Machine for forming, ditching, deep fertilizing and covering in paddy field

A deep ditch and paddy field technology, applied to fertilization devices, excavation/covering of ditch holes, application, etc., can solve problems such as poor anti-sludge water backflow effect, inconvenient adjustment of fertilization lateral offset, fertilizer water surface drift, etc., to achieve Prevent the backflow of muddy water from damaging the ditch type, structure and function design, and the effect of stabilizing the depth of fertilizer application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

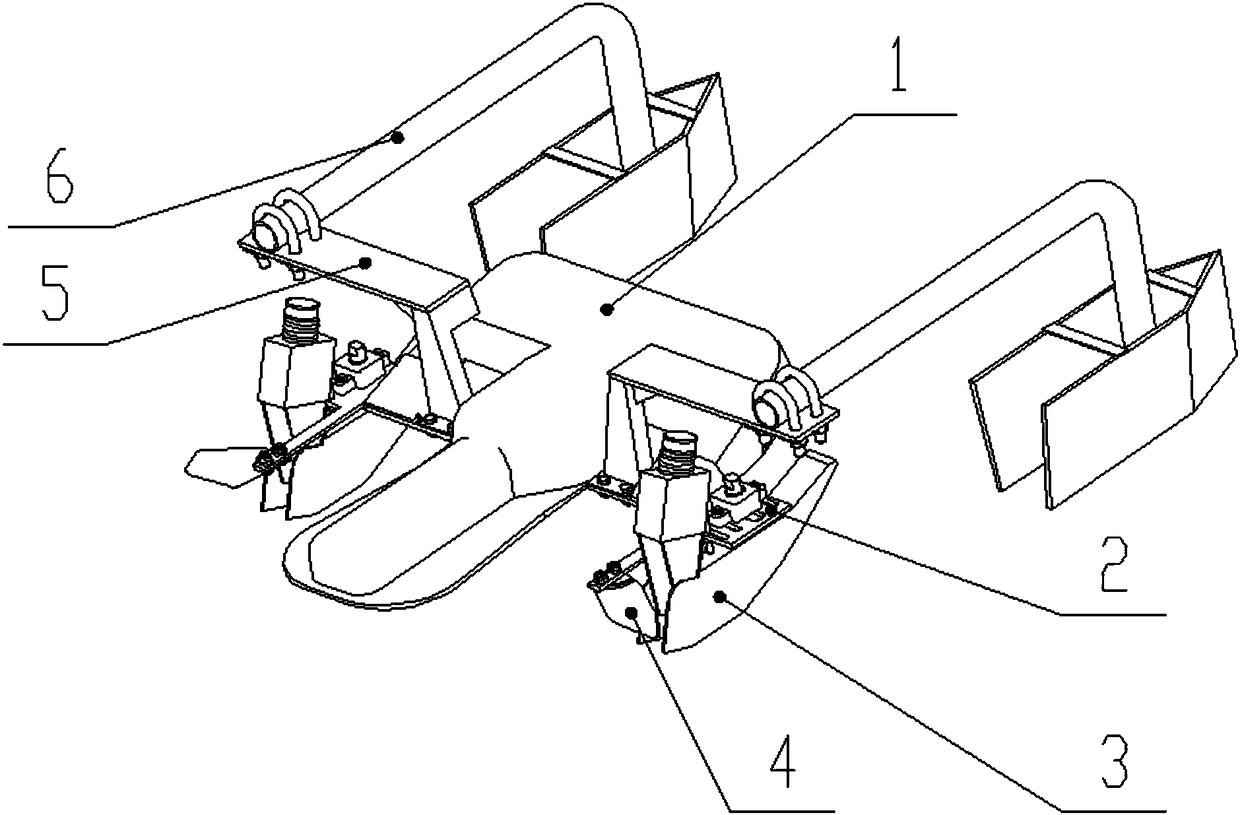

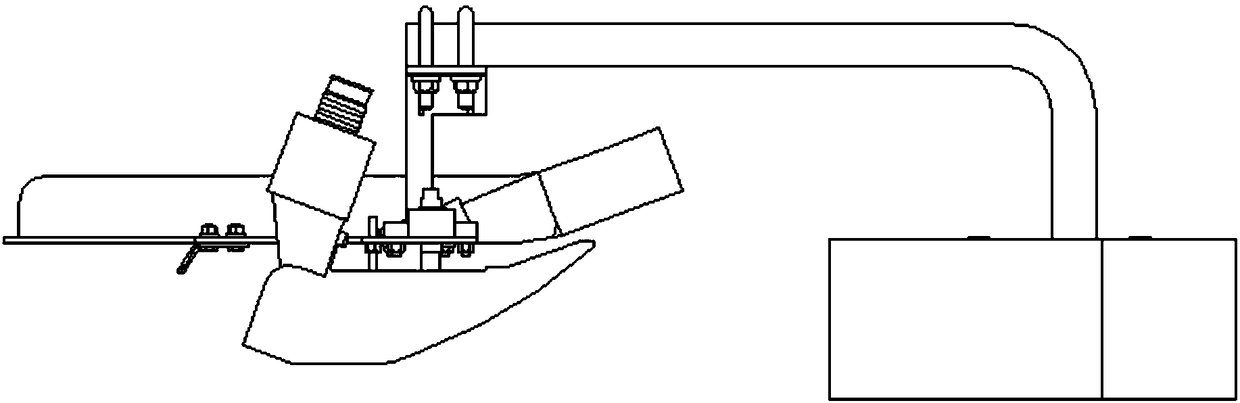

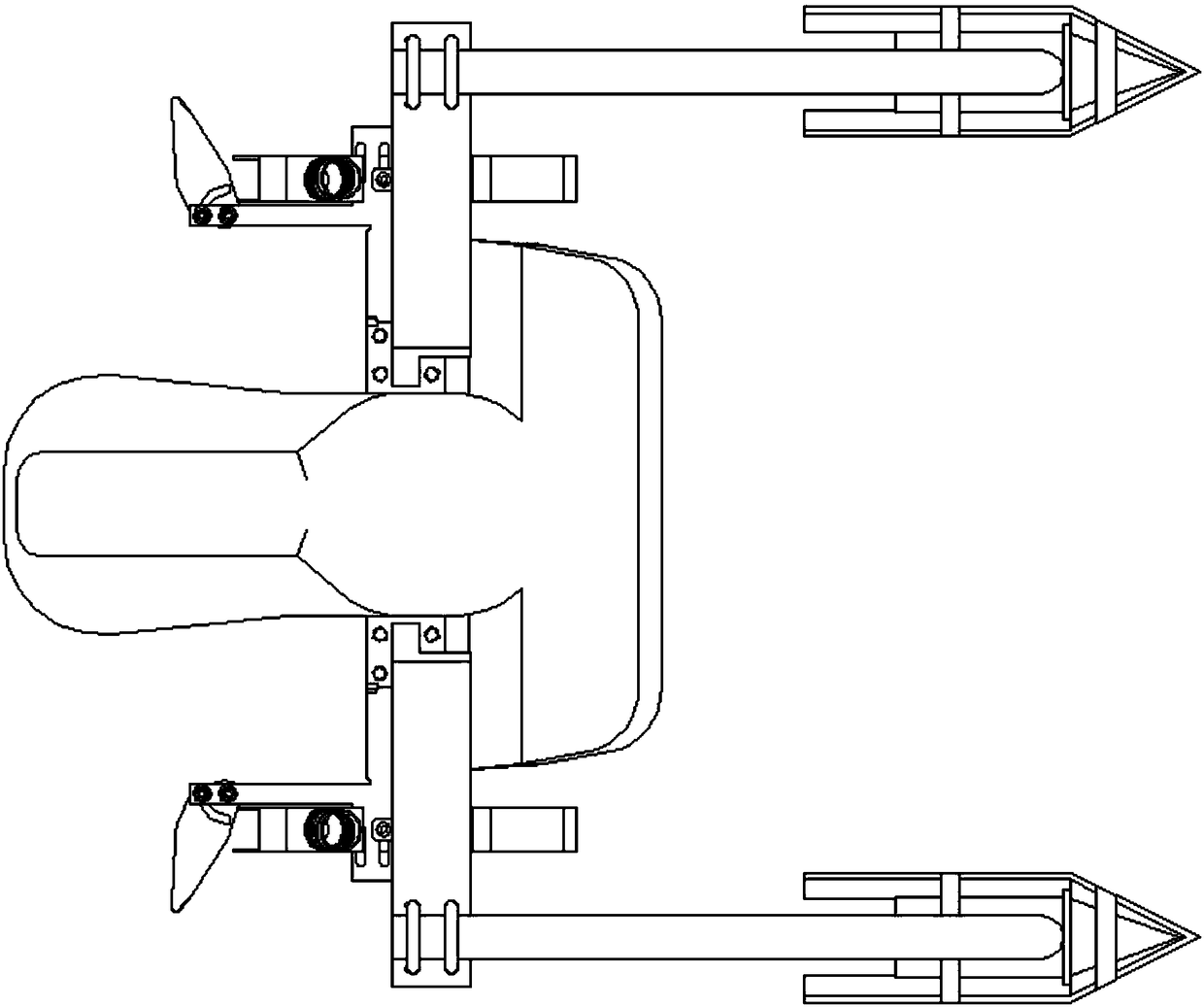

[0042] see Figure 1-Figure 18 , a forming ditch deep fertilization and soil covering device for paddy fields, comprising a floating plate 1, a pair of connecting plates 2, a pair of open side fertilizer ditch devices 3, a pair of soil covering plates 4, and a pair of water ditch devices 6; The connecting plate 2 is T-shaped, and the two sides of the first end of the connecting plate respectively have a first group of fixing holes and a second group of fixing holes, and the second end of the connecting plate has a third group of fixing holes; the first group of fixing holes Used for fixed connection with the floating plate 1, the second group of fixing holes has a plurality of holes that can be connected with the open side fertilization ditch device 3 along the side offset direction; The hole position of the open water ditch connection device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com