A self-propelled shredding equipment for livestock pasture

A self-propelled, equipment-based technology, applied to cutting equipment, applications, agricultural machinery and tools, etc., can solve the problems of low efficiency, large speed and slow speed, and achieve the effect of high efficiency, fast speed and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

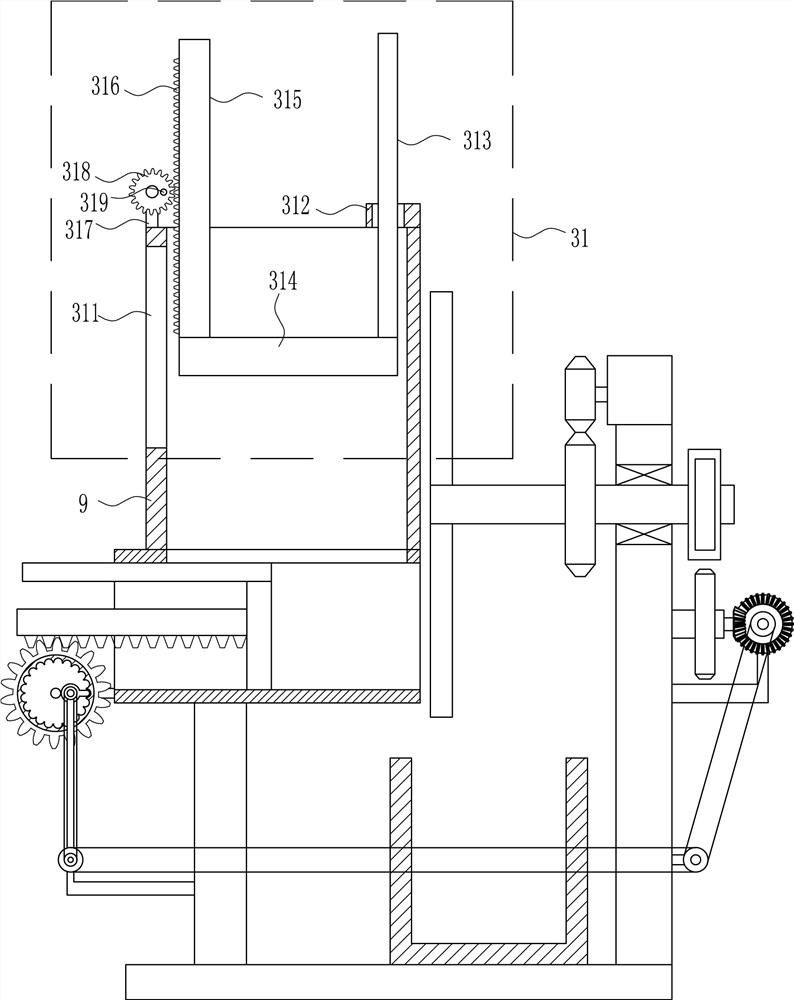

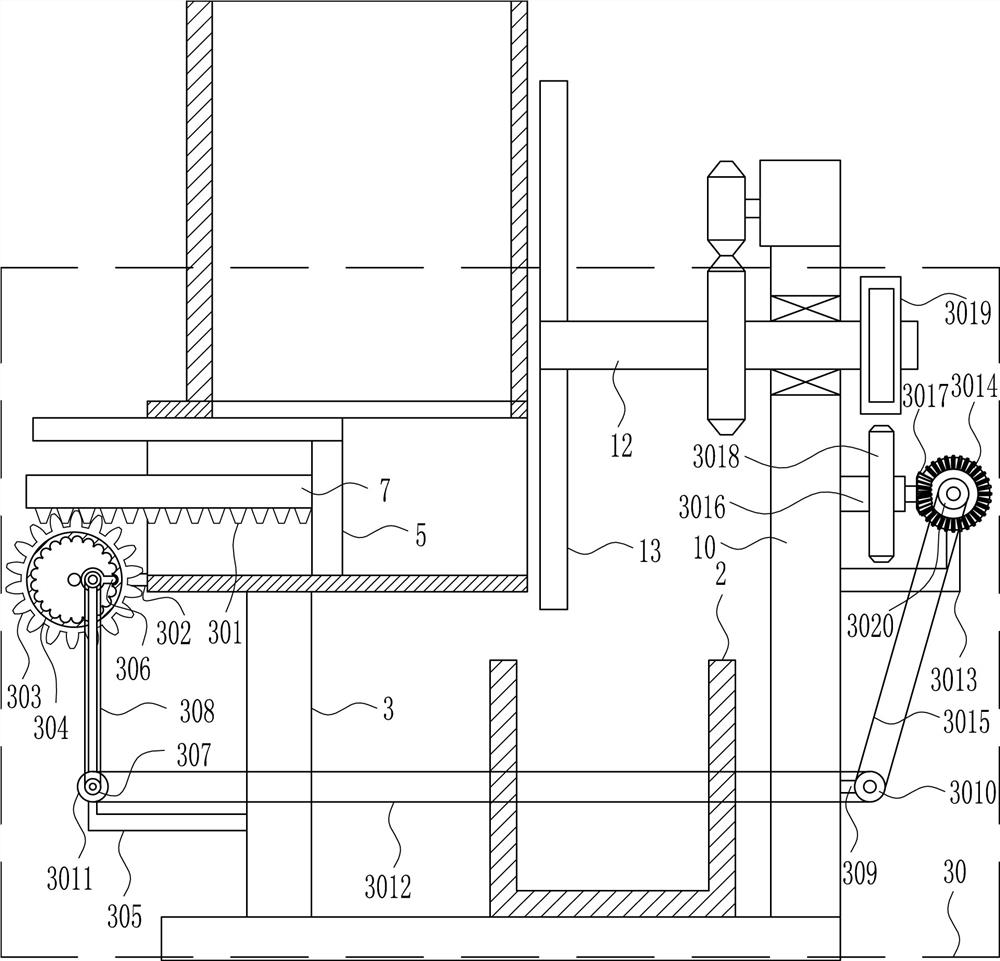

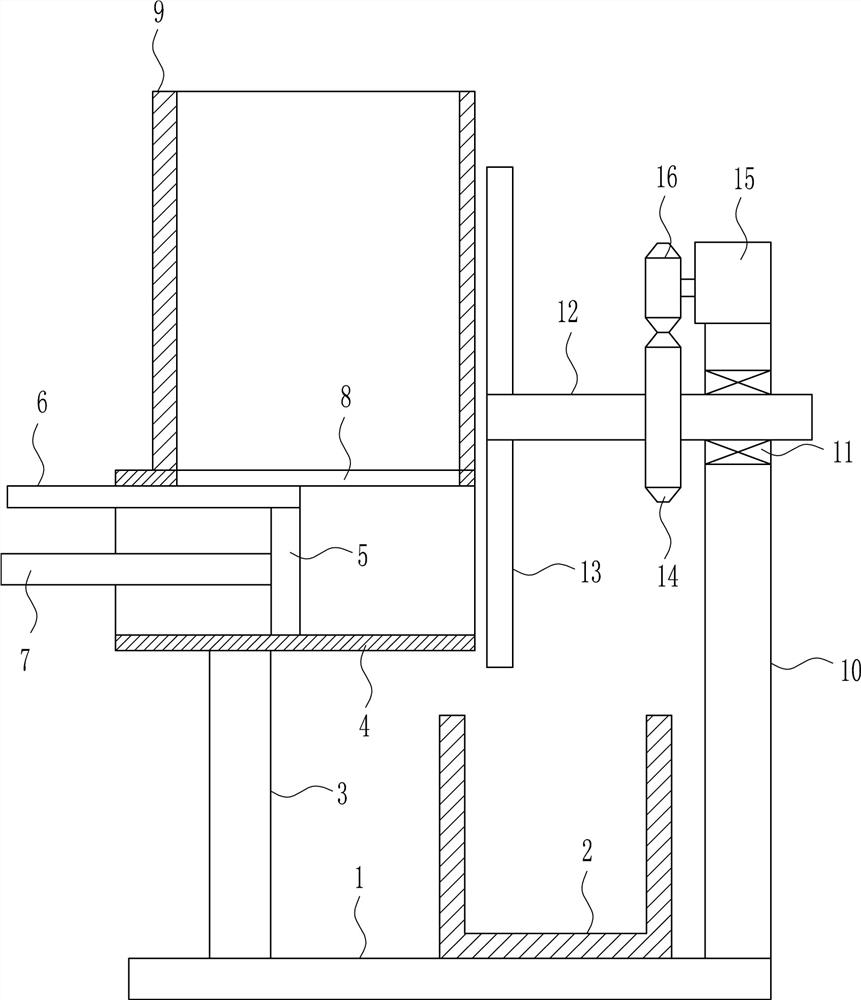

Embodiment 1

[0026] A self-progressive chopping equipment for pasture for livestock, such as Figure 1-5 As shown, it includes base plate 1, collection box 2, support rod 3, telescopic sleeve 4, push block 5, first baffle plate 6, push rod 7, placement sleeve 9, fixed rod 10, bearing seat 11, first rotating rod 12. Cutter 13, first gear 14, reduction motor 15 and second gear 16, collection box 2 is placed on the right side of base plate 1, support rod 3 is installed on the left side of base plate 1 by welding, and the upper end of support rod 3 A telescopic sleeve 4 is installed, and the telescopic sleeve 4 is slidably connected with a push block 5, the upper end of the push block 5 is connected with a first baffle plate 6, the left side of the push block 5 is connected with a push rod 7, and the upper right side of the telescopic sleeve 4 is opened with a The blanking hole 8, the first baffle plate 6 blocks the blanking hole 8, the upper side of the telescopic sleeve 4 is connected with a...

Embodiment 2

[0028] A self-progressive chopping equipment for pasture for livestock, such as Figure 1-5 As shown, it includes base plate 1, collection box 2, support rod 3, telescopic sleeve 4, push block 5, first baffle plate 6, push rod 7, placement sleeve 9, fixed rod 10, bearing seat 11, first rotating rod 12. Cutter 13, first gear 14, reduction motor 15 and second gear 16, collection box 2 is placed on the right side of base plate 1, support rod 3 is installed on the left side of base plate 1 by welding, and the upper end of support rod 3 A telescopic sleeve 4 is installed, and the telescopic sleeve 4 is slidably connected with a push block 5, the upper end of the push block 5 is connected with a first baffle plate 6, the left side of the push block 5 is connected with a push rod 7, and the upper right side of the telescopic sleeve 4 is opened with a The blanking hole 8, the first baffle plate 6 blocks the blanking hole 8, the upper side of the telescopic sleeve 4 is connected with a...

Embodiment 3

[0031] A self-progressive chopping equipment for pasture for livestock, such as Figure 1-5 As shown, it includes base plate 1, collection box 2, support rod 3, telescopic sleeve 4, push block 5, first baffle plate 6, push rod 7, placement sleeve 9, fixed rod 10, bearing seat 11, first rotating rod 12. Cutter 13, first gear 14, reduction motor 15 and second gear 16, collection box 2 is placed on the right side of base plate 1, support rod 3 is installed on the left side of base plate 1 by welding, and the upper end of support rod 3 A telescopic sleeve 4 is installed, and the telescopic sleeve 4 is slidably connected with a push block 5, the upper end of the push block 5 is connected with a first baffle plate 6, the left side of the push block 5 is connected with a push rod 7, and the upper right side of the telescopic sleeve 4 is opened with a The blanking hole 8, the first baffle plate 6 blocks the blanking hole 8, the upper side of the telescopic sleeve 4 is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com