Production method of rapid diffusion and absorption urine-leakage-prevention absorption product and diaper product

An absorbent product and a production method technology, applied in the field of sanitary products, can solve the problems of easy omission, leakage of urine, etc., and achieve the effects of increasing the effective use area, improving dryness and absorption, and solving poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

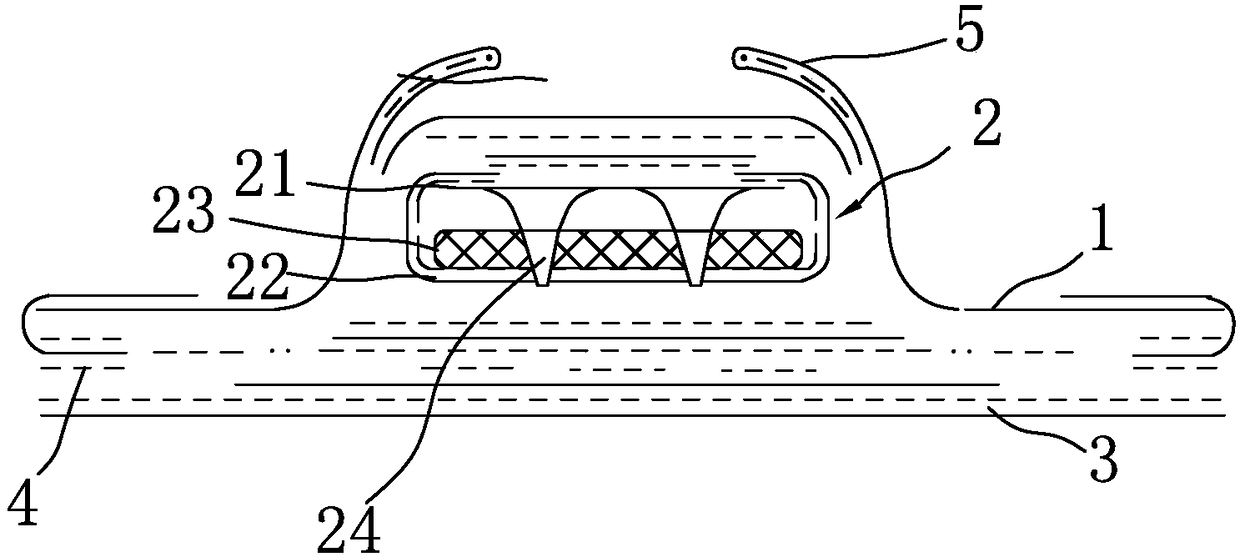

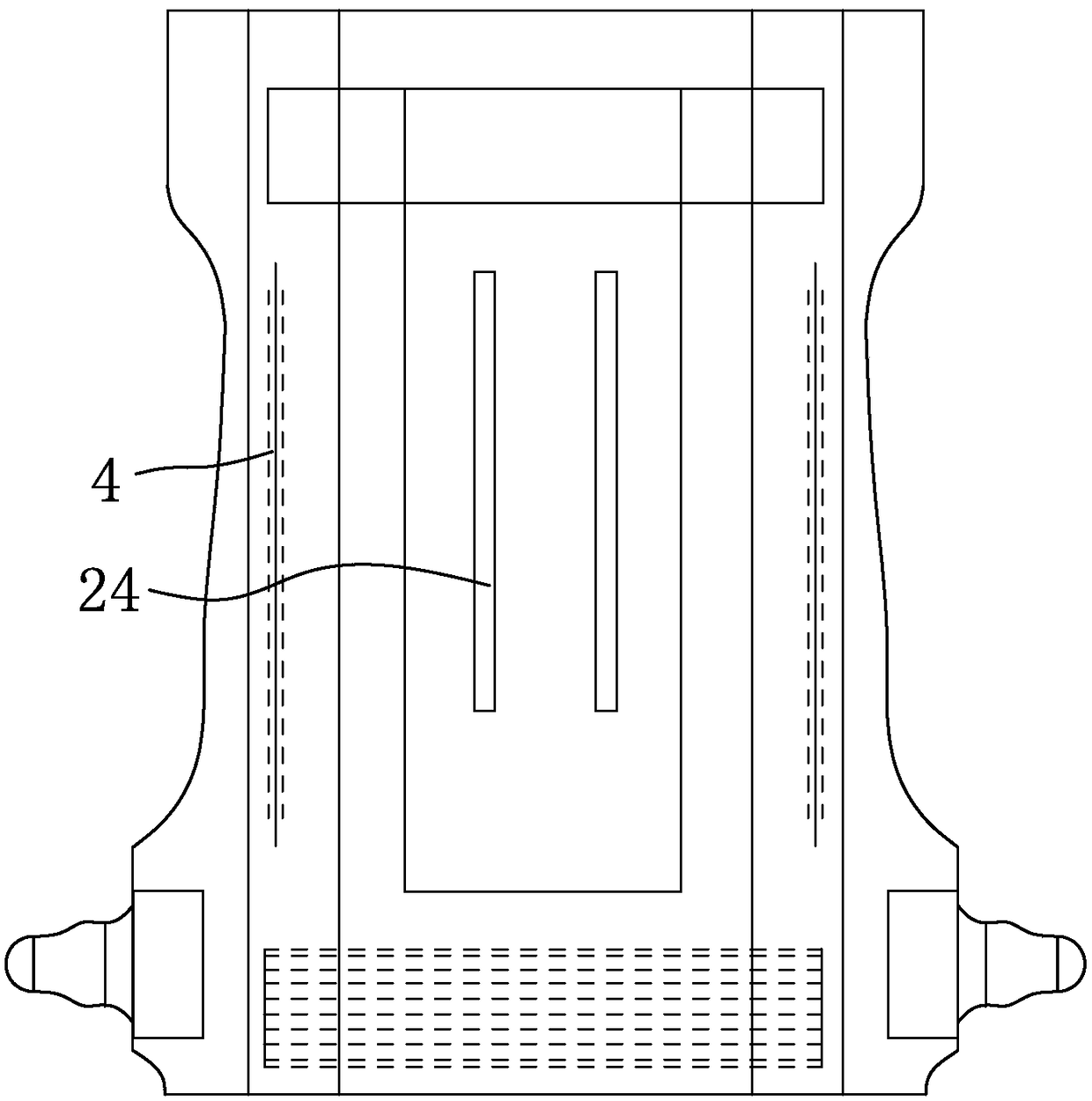

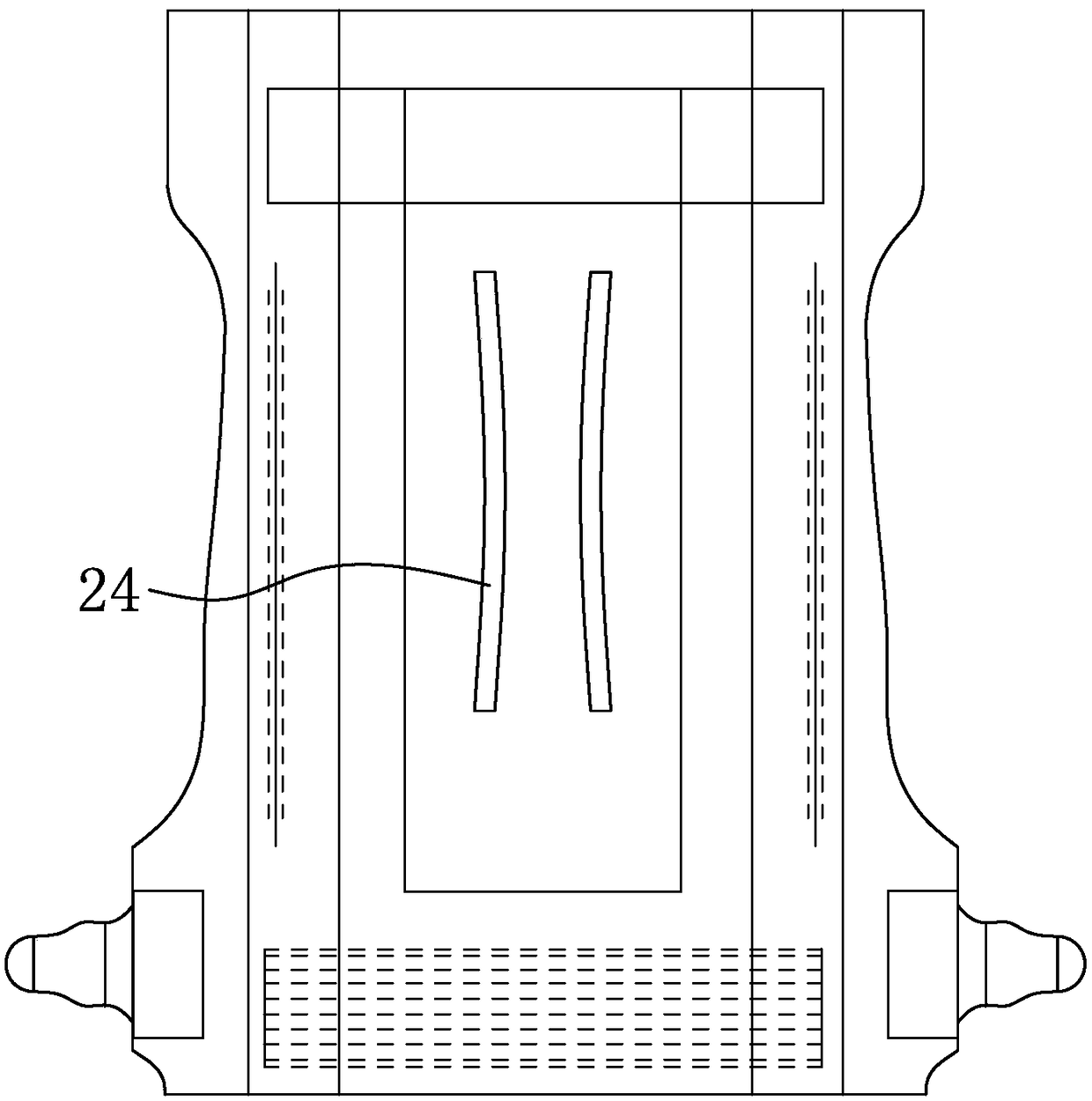

[0033] A production method for rapidly diffusing and absorbing urine leakage prevention absorbent articles, comprising the following steps:

[0034] 1. In the core body forming stage, a forming block is arranged on the forming die of the core body. When the core body is formed, it is affected by the forming block. forming a directional shaping groove with the same contour as the forming block;

[0035] 2. Squeeze the directional shaping groove under negative pressure in step (1) to fix the structure of the directional shaping groove;

[0036] 3. Spray the adhesive at the directional shaping groove, and then compound the upper wrapping layer on the upper surface of the fluff pulp and the polymer mixture, and perform a hot-pressing circumferential sealing;

[0037] 4. Bonding the upper wrapping layer and the lower wrapping layer by hot pressing, ultrasonic wave or gluing method at the directional shaping groove;

[0038] 5. Compound the surface material and the bottom material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com