Self-excitation type hydraulic cleaning tool

A cleaning tool and self-excited technology, which is applied in cleaning methods and utensils, cleaning hollow objects, spraying devices, etc., can solve problems such as unsatisfactory effects, inability to clean in all directions, easy deposition of dirt, etc., and achieve efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

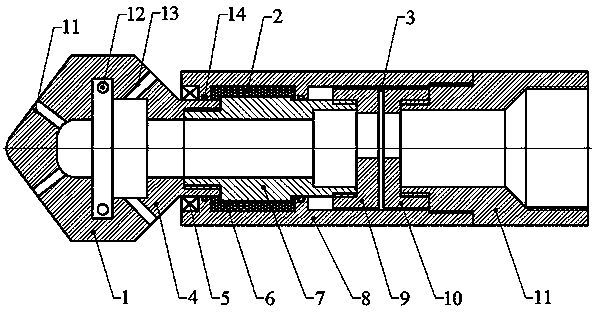

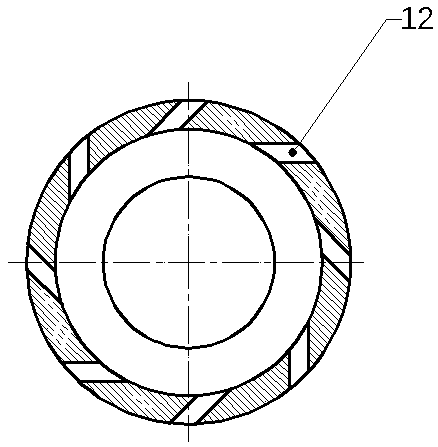

[0022] like figure 1 and figure 2 As shown, the present invention provides a self-excited hydraulic cleaning tool, including a spin mechanism 1 , a speed limiting mechanism 2 and a pulse mechanism 3 . Wherein the spin mechanism 1 includes a spin nozzle 4, the head of the spin nozzle 4 is provided with a forward hole 11, the side is provided with a tangential hole 12 and the side rear is provided with a rearward hole 13; the speed limiting mechanism 2 includes Outer casing 8, ball bearing 5 is installed on the outer circle of the tail of spin nozzle 4 and ball bearing 5 is installed and fixed on the inner side of outer casing 8, the interference fit between the outer casing 8 and ball bearing 5; There is a mandrel 7 with openings at both ends, two sets of sealing rings 14 are installed between the outer casing 8 and the mandrel 7, and the chamber 6 between the inner side of the outer casing 8, the outer side of the mandrel 7 and the sealing ring 14 is filled with viscous damp...

specific Embodiment 2

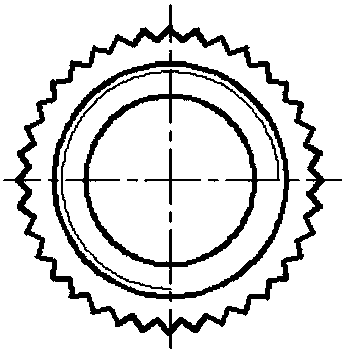

[0023] like image 3 As shown, on the basis of Embodiment 1, preferably, teeth are processed on the outer circle of the mandrel 7, and the height of the teeth is 5-7mm.

[0024] The effect of its improvement is that this technical feature can enhance the shear viscous damping fluid, and the resistance increases with the increase of the speed, which acts as a speed limiter, prevents the water flow from the nozzle from being scattered when the rotation speed is too high, and reduces the impact force.

[0025] It can be concluded that the jet nozzles in the above two embodiments generate forward jets to clean the dirt on the front end; the tangential jets clean the dirt on the circumference for a second time and generate tangential force to rotate the nozzles and form The swirling flow field can realize all-round cleaning; while the backward jet cleans the pipeline, the dirt is discharged backward. The pulse mechanism is that two eccentric holes move relative to each other. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com