Isometric cutting device

A cutting device and equal-length technology, applied in shearing devices, accessories of shearing machines, manufacturing tools, etc., can solve the problem of inability to achieve equal-length cutting of parts, reduce manual labor, improve processing efficiency, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

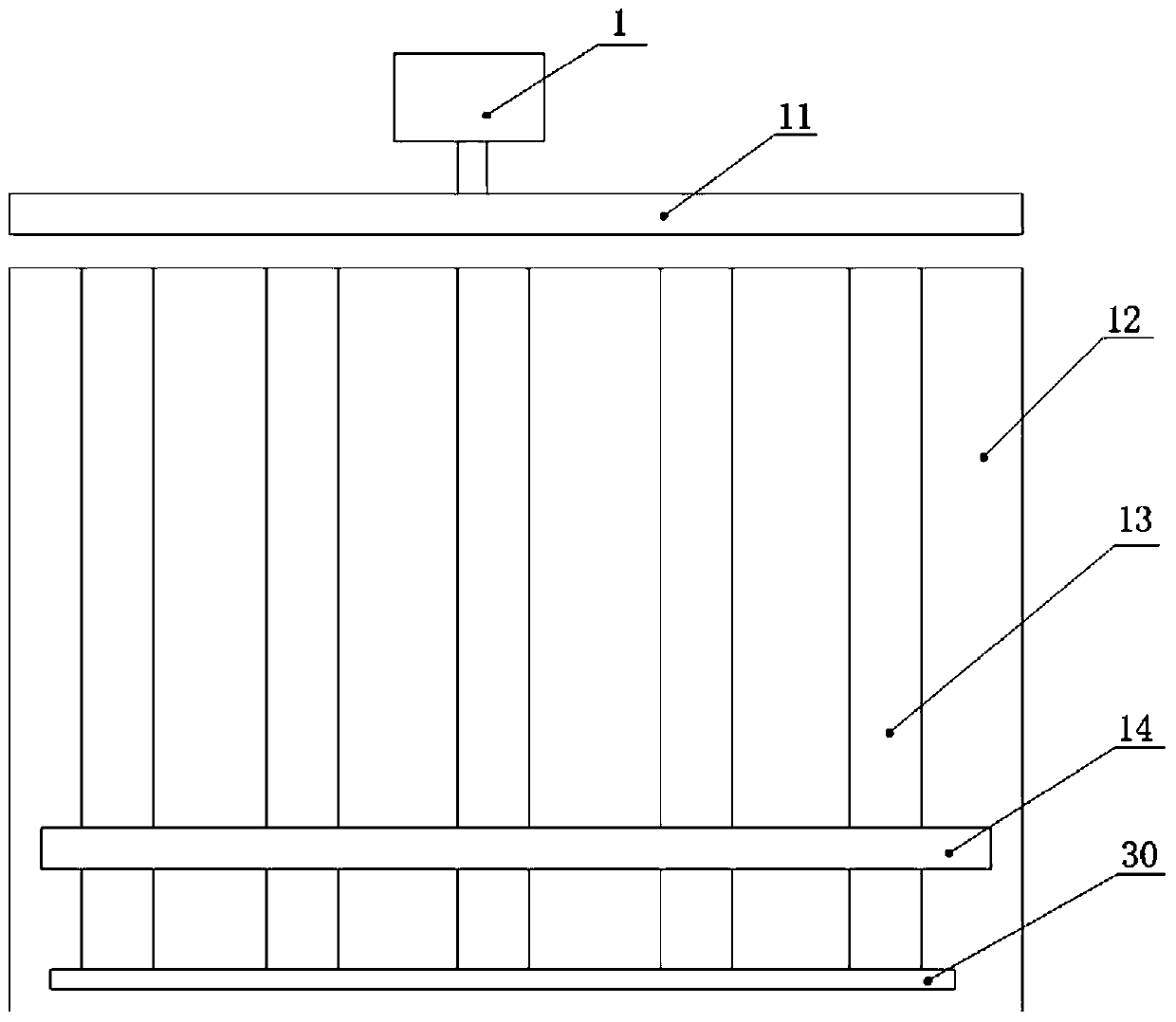

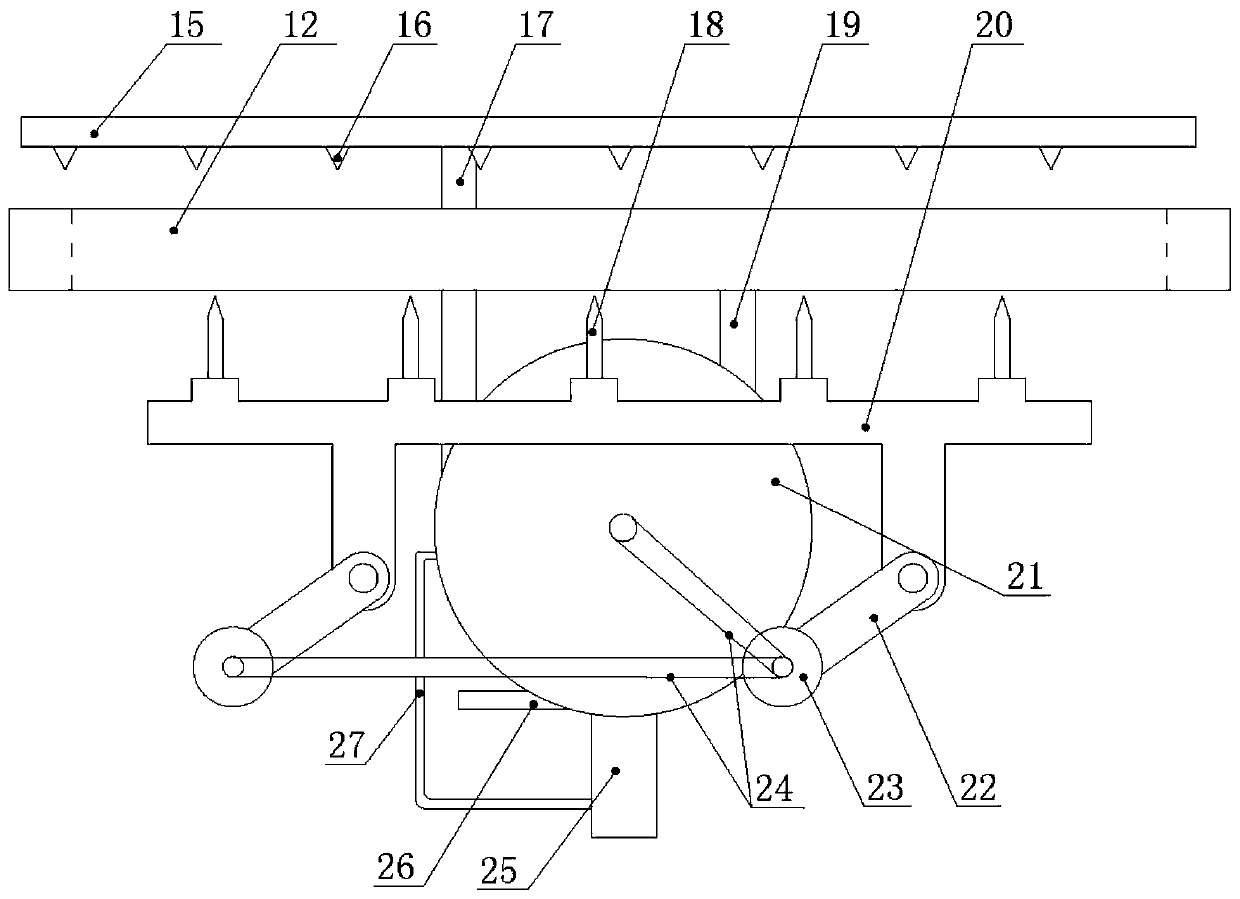

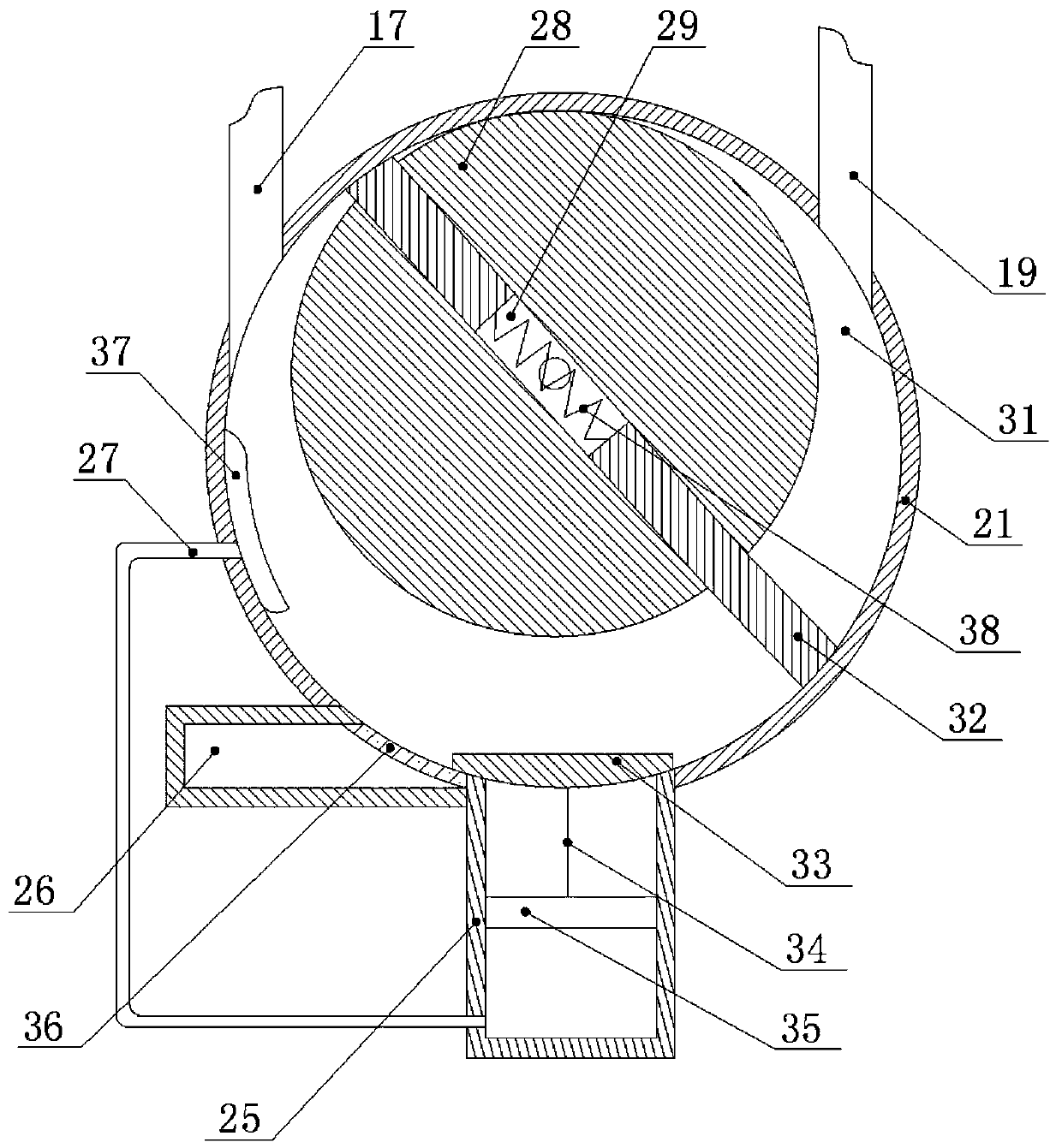

[0022] The reference signs in the drawings of the description include: cylinder 1, push plate 11, processing table 12, placement groove 13, cutting hole 14, cooling pipe 15, nozzle 16, air outlet pipe 17, cutter 18, air inlet pipe 19, knife holder 20. Cylinder 21, connecting rod 22, runner 23, belt 24, water pipe 25, escape pipe 26, branch pipe 27, driving column 28, chute 29, limit plate 30, air cavity 31, slide plate 32, sealing plate 33, rope 34, magnet 35, elastic cloth 36, air bag 37, spring 38.

[0023] Such as figure 1 As shown, the equal-length cutting device of the present invention comprises a processing table 12, and a plurality of placing grooves 13 are vertically and parallelly opened on the processing table 12, and a push plate 11 is horizontally installed at the rear end of the placing groove 13, and the push plate 11 is connected with a pushing mechanism, which drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com