Anti-vibration atomizing grinding device

An anti-vibration, atomizing nozzle technology, used in grinding/polishing safety devices, grinding machines, grinding frames, etc., can solve the problems of inability to remove dust, increase work efficiency, and low processing efficiency, and reduce vibration fatigue. , Improve the comfort of use and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment.

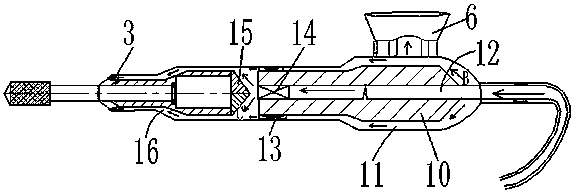

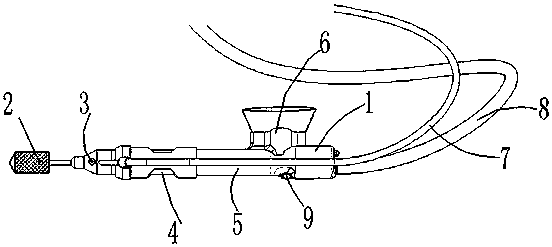

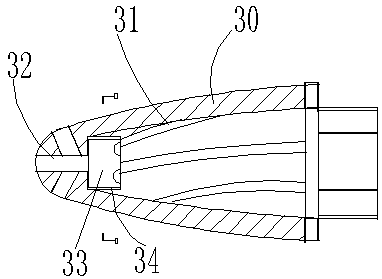

[0016] An anti-vibration atomization grinding device of the present invention is mainly composed of a housing 1, a grinding head 2, an atomizing nozzle 3, a switch 4, a shell back seat 5, a drying nozzle 6, a circulating water pipe 7, a double channel pipe 8, a drying Nozzle switch button 9, diverter block 10, air flow channel B11, water flow channel A12, No. 1 electromagnetic switch valve 13, No. 2 electromagnetic switch valve 14, motor mounting seat 15, atomizing nozzle housing 30, spiral groove 31, air outlet nozzle 32 , guide block 33, gasification through hole 34, outer tube 61, inner tube 62, spiral guide rib 63, water flow channel 64, air channel 65.

[0017] The device includes a housing 1, a grinding head 2, and an atomizing nozzle 3. The front end of the housing 1 is provided with a grinding head 2, the grinding head 2 is connected to the motor output shaft in the motor mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com