Rubber band winding machine

A winding machine and rubber band technology, which is applied in the field of rubber band winding machines, can solve the problems of uneven quality and low efficiency of rubber band winding machines, and achieve the effects of reducing production costs, improving quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

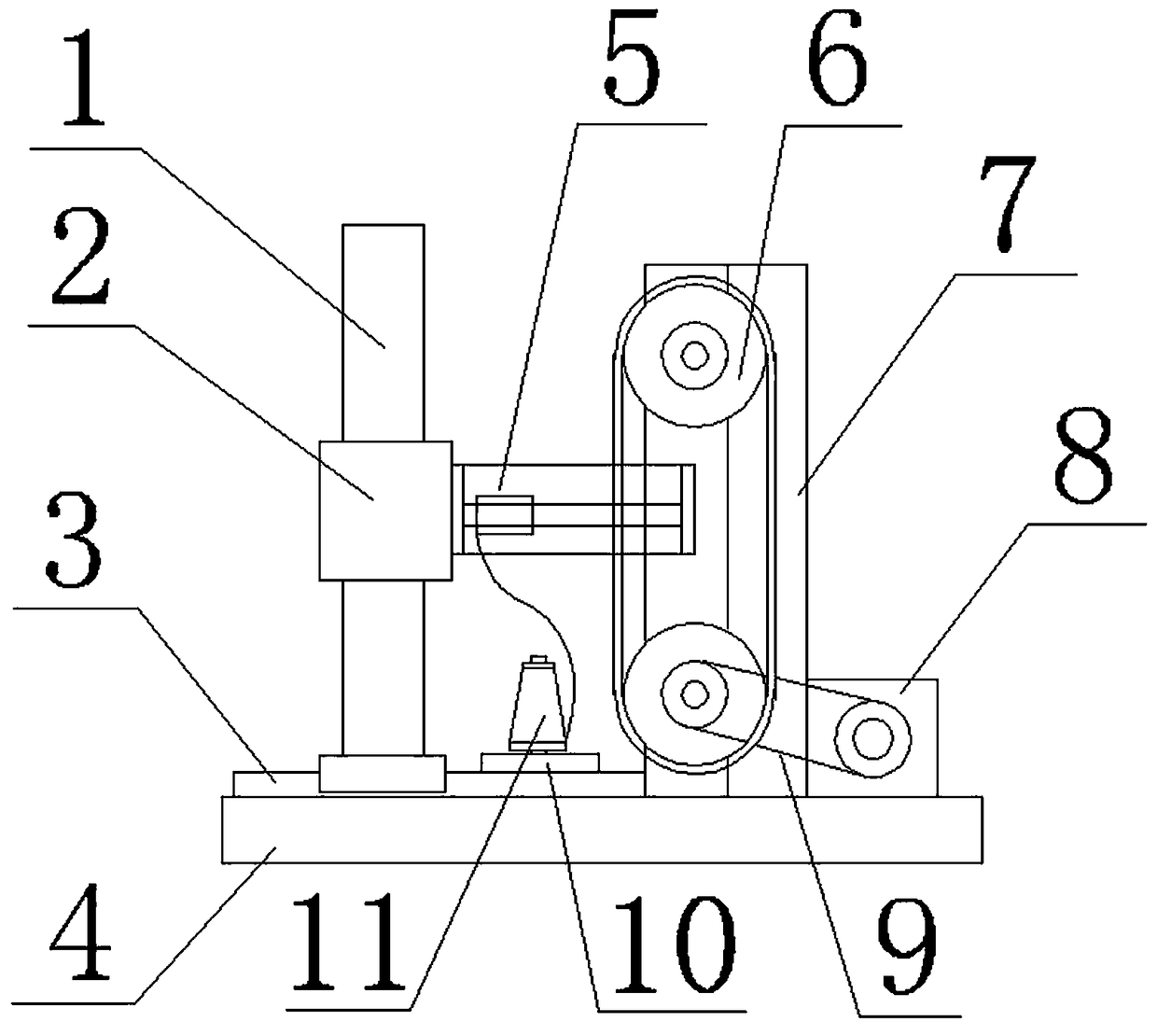

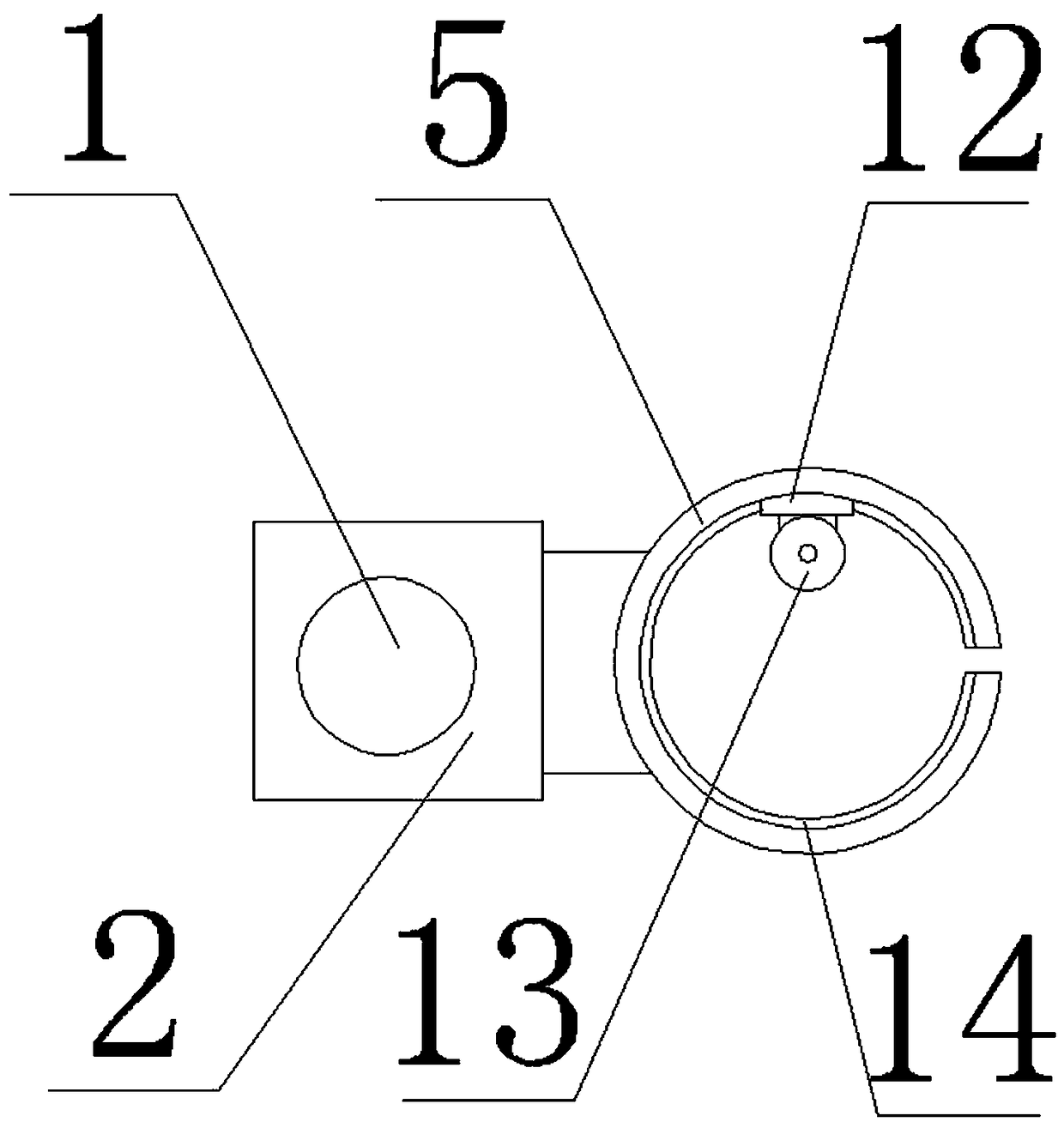

[0017] A rubber band winding machine, comprising a base 4, a winding device 5 and a rubber band fixing device 7, the base 4 is provided with a slide rail 3, the column 1 is arranged on the slide rail 3 through a walking device, and the winding The device 5 is arranged on the column 1 by the drive mechanism 2, the inside of the winding device 5 is provided with a track 14, the wool fixer 13 is arranged on the track 14 through the walking device 12, the wool bobbin fixer 10 is arranged below the winding device 5, and the wool Tube 11 is installed on the bobbin holder 10, and described rubber band fixing device 7 is arranged on the right side of winding device 5, and rubber band fixing device 7 top is driven wheel 6, and below is driving wheel 9, and driving wheel 9 passes belt and right side. The motor 8 on the side is connected. An application method of a rubber band winding machine is as follows: the operator puts the rubber band between the driven wheel 6 and the driving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com