Anti-leakage wastewater reaction equipment

A reaction equipment and anti-leakage technology, applied in water pollutants, water treatment parameter control, neutralized water/sewage treatment, etc. The effect of improving biochemical properties and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] As a basic example:

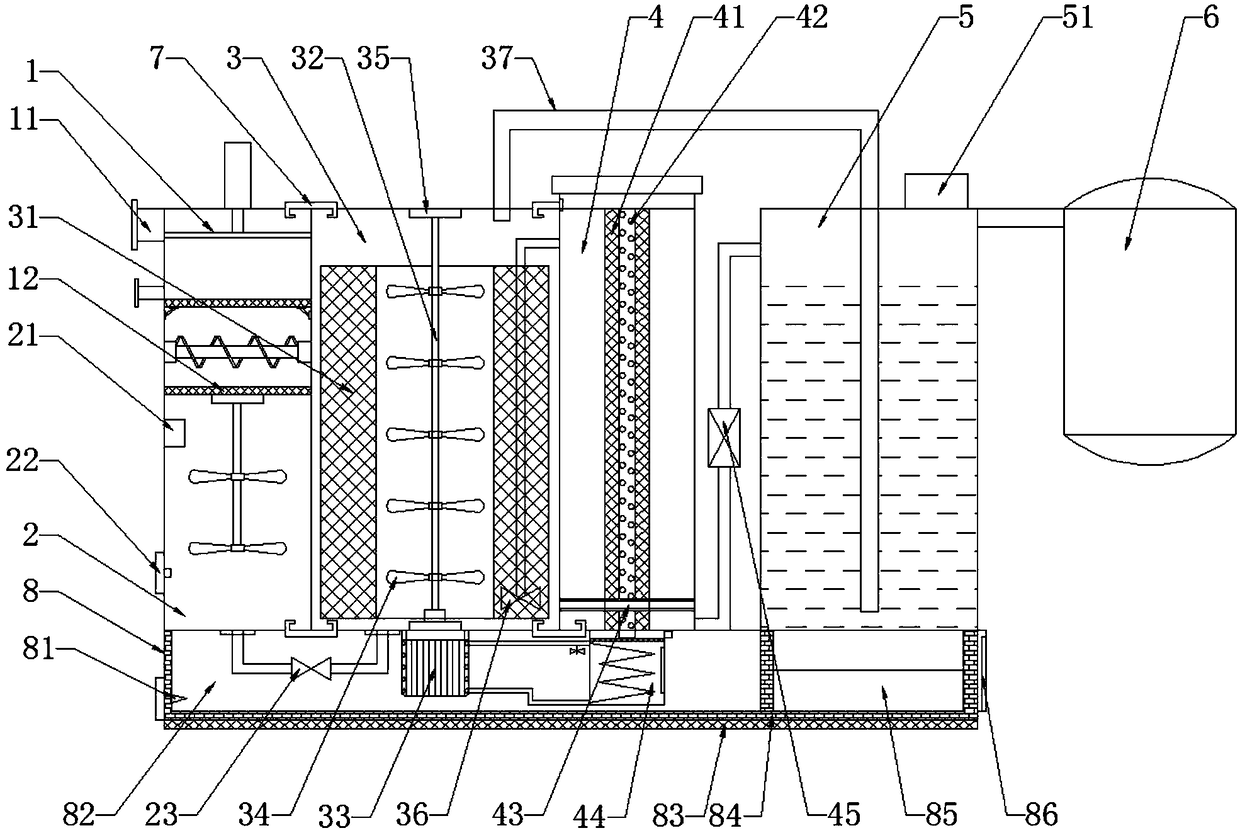

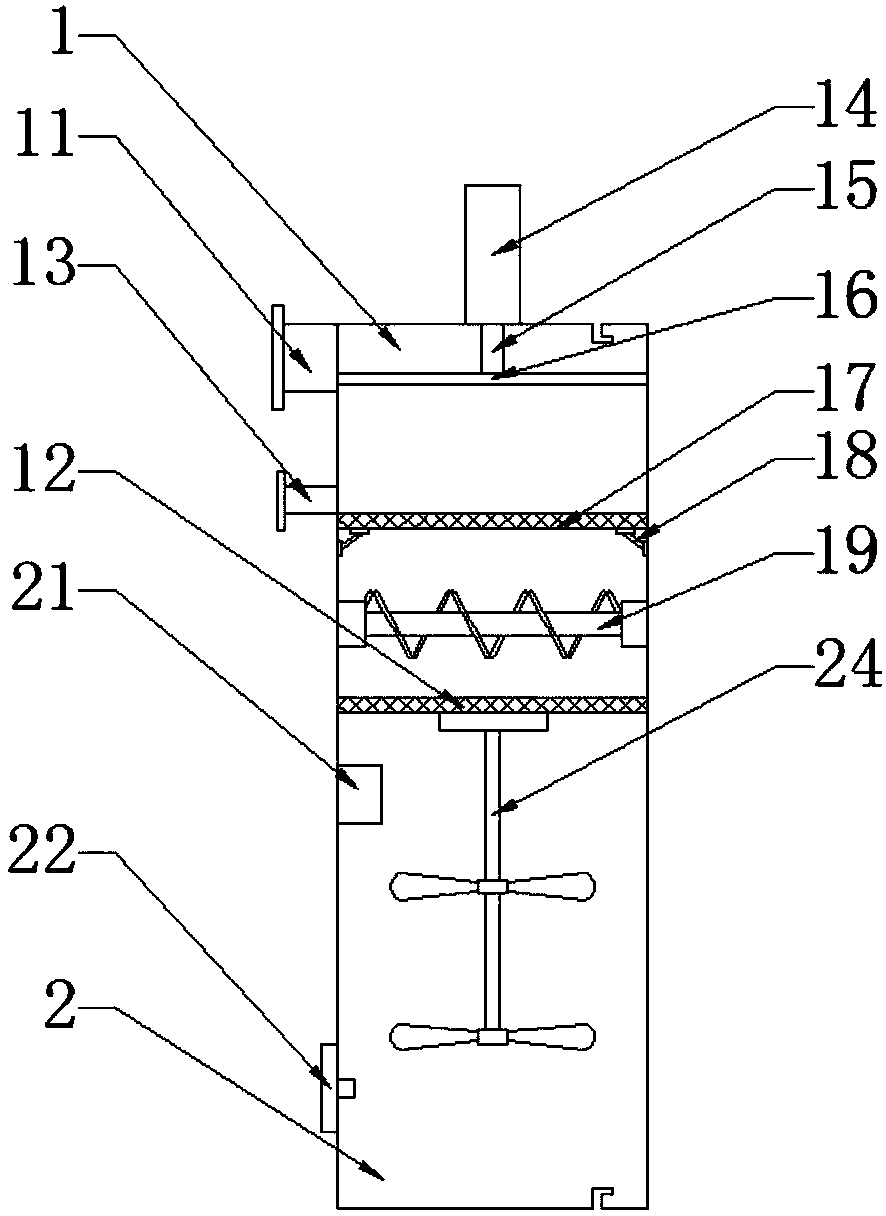

[0045] A kind of anti-leakage wastewater reaction equipment, including sedimentation well 1, regulating pond 2, anaerobic pond 3 and aerobic pond 4, described regulating pond 2 is connected with anaerobic pond 3, and described anaerobic pond 3 is connected with aerobic pond The tanks 4 are connected together, and it is characterized in that a hydraulic cylinder 14 is installed on the top surface of the settling well 1, and a hydraulic rod 15 located in the settling well 1 is connected under the hydraulic cylinder 14, and a hydraulic rod 15 is connected under the hydraulic rod 15. Filter plate 16, the inwall of sedimentation well 1 is equipped with the press filter screen 17 that is positioned at described press filter plate 16 below, and the inwall of the sedimentation well 1 below described press filter screen 17 is equipped with stirring separator 19, and described stirring A filter residue screen 12 is installed below the separator 19, a regulat...

Embodiment 2

[0048] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the top and bottom surfaces of the sedimentation well 1, the anaerobic pond 3, and the aerobic pond 4 are close to the pasting One side of the joint surface is provided with a clamping groove, and a clamping rubber strip 7 whose shape matches the clamping groove is installed in the clamping groove.

[0049] Further, the clamping rubber strip 7 is in a "concave" shape, and the ends of the two protruding parts of the "concave" shape of the clamping rubber strip 7 are connected with hooks extending toward the concave part of the clamping rubber strip 7 .

Embodiment 3

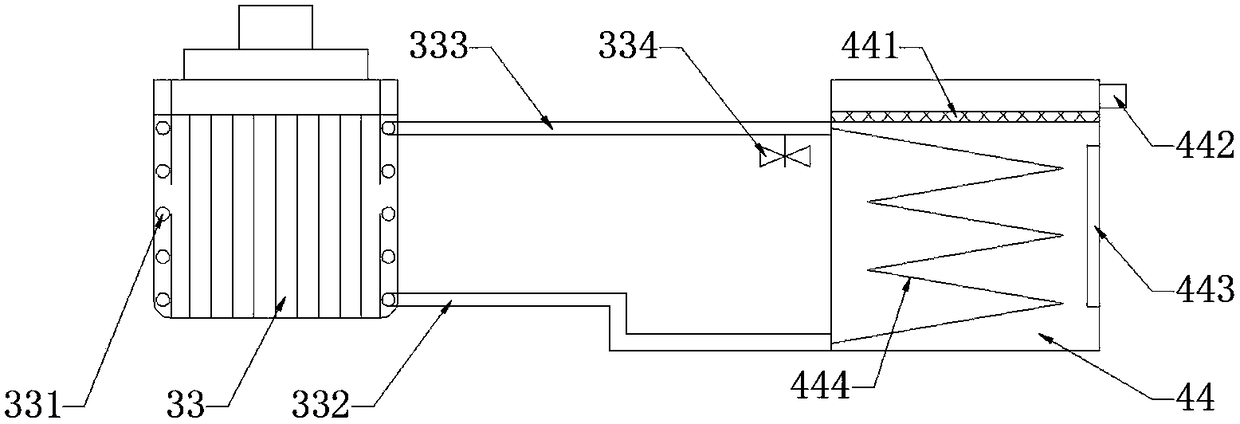

[0051] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the bottom surface of the anaerobic tank 3 is connected with a motor 33 connected to the stirring shaft 32, so Said motor 33 is provided with a spiral heat exchange tube 331, the bottom of the aerobic pool 4 is connected with an antifreeze fan 44, a heating tube 444 is installed in the antifreeze fan 44, and the upper and lower ends of the heating tube 444 are respectively connected with a spiral The upper end of the heat exchange pipe 331 is connected to the liquid outlet pipe 333 and the liquid inlet pipe 332 connected to the upper end. The liquid outlet pipe 333 is connected with an antifreeze valve 334, and a heating net 441 is installed above the antifreeze fan 44. A thermometer 442 is connected above the side, and an inspection door 443 is also installed on the side of the antifreeze fan 44 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com