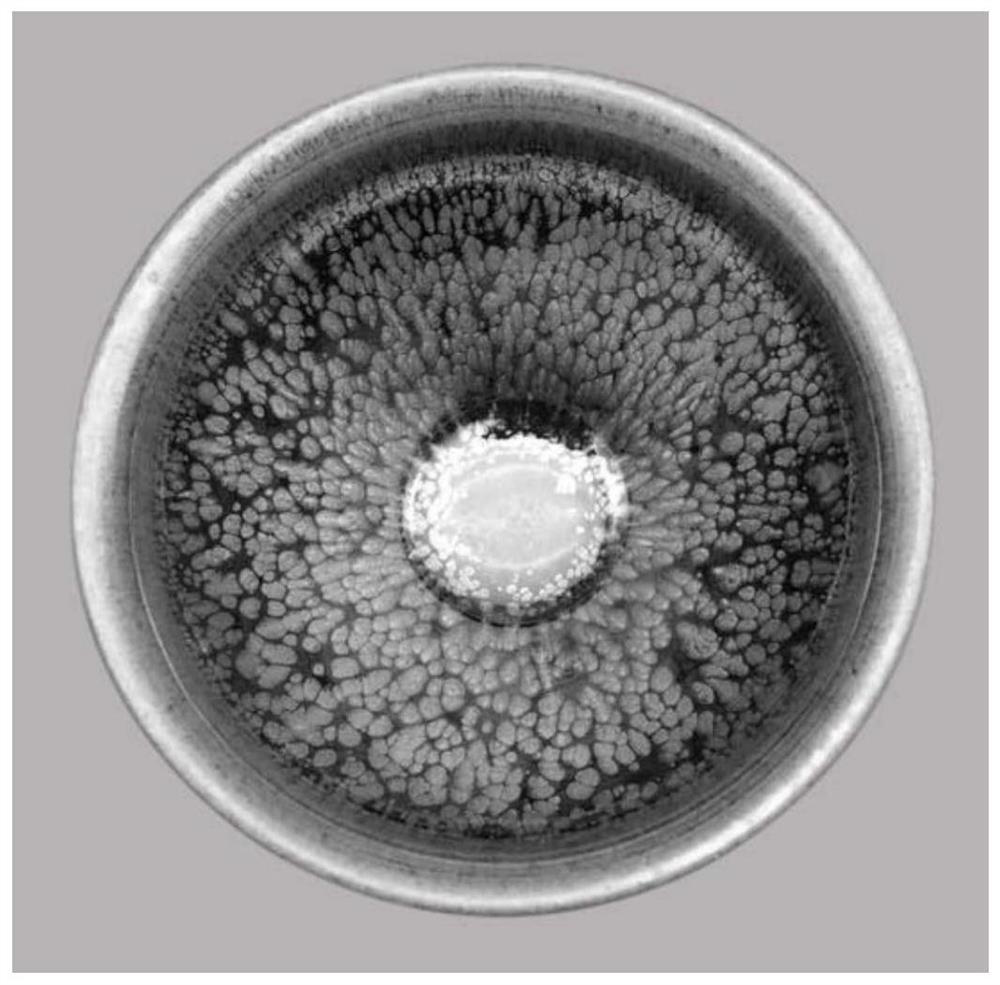

Firing method of traditional black-glazed silver oil-drop Jianzhan

A black glaze, traditional technology, applied in the firing field of Jianzhan, can solve the problems of difficult control formula, firing atmosphere and temperature curve, crystal pattern does not display, high difficulty of firing, etc., to achieve good vitrification effect, three-dimensional Strong sense and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The firing method of the traditional black-glazed silver oil-drop Jianzhan includes the following steps:

[0031] (1) Green body preparation: take 50 parts by weight of kaolin, 30 parts by weight of field soil, and 20 parts by weight of red clay, mix them in a blender and stir; pass through a 100-mesh sieve after stirring evenly to obtain mud; press filter the mud to obtain a filter cake; Put the filter cake into the mud refiner to vacuumize the mud, the pressure of mud refining is 0.1MPa, repeat the mud refining 3 times, each time 15s, to get the mud material;

[0032] (2) Forming of the blank body: the mud material is manually drawn into the blank, dried, and trimmed;

[0033] (3) Bisque firing of the green body; during biscuit firing, the furnace door is opened with a gap width of 8-10 cm, and the furnace temperature rises from normal temperature to 300°C. Then close the furnace door, the temperature continues to rise to 850 ° C, keep warm for 6 hours, stop the furn...

Embodiment 2

[0044] The firing method of the traditional black-glazed silver oil-drop Jianzhan includes the following steps:

[0045] (1) Green body preparation: take 45 parts by weight of kaolin, 30 parts by weight of field soil, and 18 parts by weight of red clay, mix them in a blender and stir; pass through an 80-mesh sieve after stirring evenly to obtain mud; press filter the mud to obtain a filter cake; Put the filter cake into the mud refining machine to vacuumize the mud, the pressure of the mud refining is 0.08MPa, repeat the mud refining 4 times, each time for 10s, and get the mud material;

[0046] (2) Forming of the blank body: the mud material is manually drawn into the blank, dried, and trimmed;

[0047] (3) Bisque firing of the green body; during biscuit firing, the furnace door is opened with a gap width of 8-10 cm, and the furnace temperature rises from normal temperature to 290°C. Then close the furnace door, the temperature continues to rise to 840 ° C, keep warm for 7 h...

Embodiment 3

[0058] The firing method of the traditional black-glazed silver oil-drop Jianzhan includes the following steps:

[0059] (1) Green body preparation: take 55 parts by weight of kaolin, 27 parts by weight of field soil, and 24 parts by weight of red clay, mix them and add them to a blender for stirring; pass through a 90-mesh sieve after stirring evenly to obtain mud; press filter the mud to obtain a filter cake; Put the filter cake into the mud refiner to vacuumize the mud, the pressure of the mud is 0.09MPa, repeat the mud refining 6 times, each time 20s, to get the mud;

[0060] (2) Forming of the blank body: the mud material is manually drawn into the blank, dried, and trimmed;

[0061] (3) Biscuit firing; during biscuit firing, the furnace door is opened with a gap width of 8-10 cm, and the furnace temperature rises from normal temperature to 305°C. Then close the furnace door, the temperature continues to rise to 830 ° C, keep warm for 8 hours, stop the furnace, and when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com