A brush calligraphy ink correction fluid and preparation method thereof

A technology of correction fluid and calligraphy, which is applied in the direction of coating, etc., can solve the problems of calligraphy writing, error correction, ink marks, pollution, etc., and achieve the effects of reducing paper consumption, high coating efficiency, and ensuring uniformity and fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

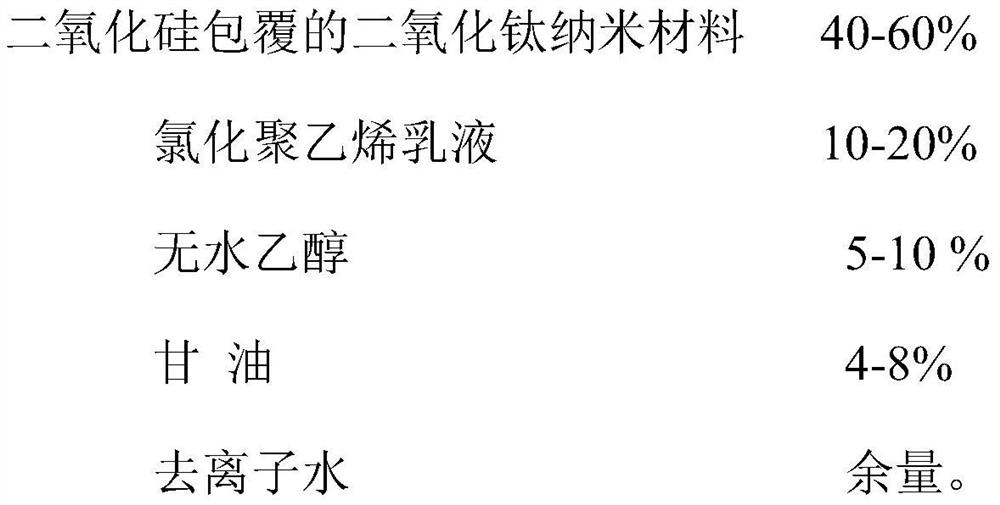

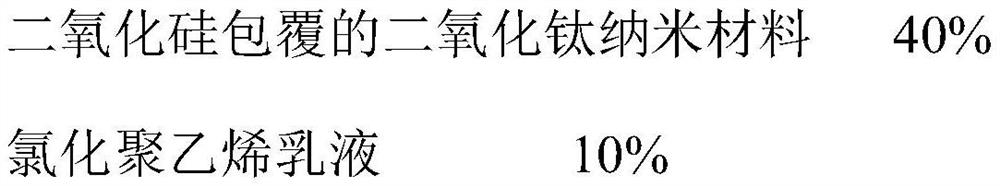

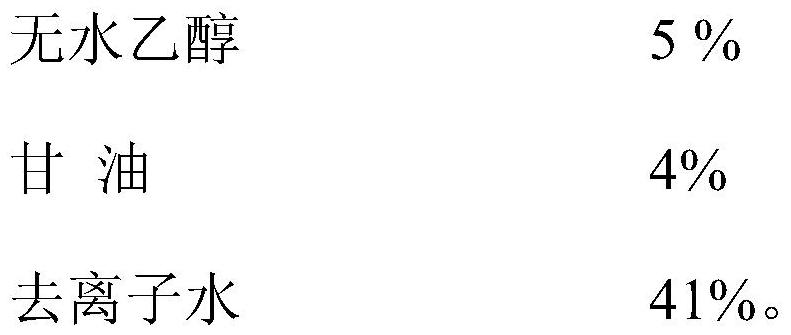

[0023] A brush calligraphic ink in this embodiment is applied, composed of the following mass percentage of raw materials:

[0024]

[0025]

[0026] The silica coated titanium dioxide nanoma is prepared from the following steps:

[0027] (1) TIO 2 Surface hydroxylation treatment: 100 mg TiO under magnetic stirring 2 P 25 The powder was added to a NaOH solution of 10 ml of a concentration of 0.5 mol / L, and stirred for 9 h, then washed with deionized water to dispersion to dispersion, it is weak to acid, to obtain TiO of surface hydroxylation treatment 2 nanomaterials;

[0028] (2) TiO of hydroxylated surface obtained by step (1) 2 The nanomaterials were dispersed into 30 ml of anhydrous ethanol, and the ultrasound was oscillated for 15 minutes to make it sufficiently dispersed, prepared for TiO 2 Nanomaterial dispersion;

[0029] (3) Ethyl orthosilicate and a mass concentration of 28% ammonia water and anhydrous ethanol are fully mixed by a volume ratio of 1: 1.1: 1, and pre...

Embodiment 2

[0034] A brush calligraphic ink in this embodiment is applied, composed of the following mass percentage of raw materials:

[0035]

[0036] The silica coated titanium dioxide nanoma is prepared from the following steps:

[0037] (1) TIO 2 Surface hydroxylation treatment: under magnetic stirring conditions, 200 mg TiO 2 P 25 The powder was added to a NaOH solution of 10 ml of 1 mol / L, and the stirring was held for 12 h, then the dispersion was washed with deionized water to the dispersion, which was weakly acidic to obtain a surface hydroxylated TiO. 2 nanomaterials;

[0038] (2) TiO of hydroxylated surface obtained by step (1) 2 The nanomaterial is dispersed into 50 mL of anhydrous ethanol, and the ultrasonic oscillation of 30 min makes it sufficiently dispersed, prepared to get TiO 2 Nanomaterial dispersion;

[0039] (3) Ethyl lysate and the mass concentration of 28% ammonia water and anhydrous ethanol are thoroughly mixed by a volume ratio of 1: 2: 2, and prepared a mixed d...

Embodiment 3

[0044] A brush calligraphic ink in this embodiment is applied, composed of the following mass percentage of raw materials:

[0045]

[0046] The silica coated titanium dioxide nanoma is prepared from the following steps:

[0047] (1) TIO 2 Surface hydroxylation treatment: under magnetic stirring conditions, 400 mg TiO2 P 25 The powder was added to a NaOH solution of 10 ml of 2 mol / L, and was allowed to be stirred for 15 h, and then washed with deionized water to centrifugally, the dispersion was weak, resulting in surface hydroxylation treatment TiO 2 nanomaterials;

[0048] (2) TiO of hydroxylated surface obtained by step (1) 2 Nanofilm material is dispersed into 80 mL of anhydrous ethanol, and the ultrasound oscillate 50min makes it fully dispersed, preparing TiO 2 Nanomaterial dispersion;

[0049] (3) Ethyl n-silicate and a mass concentration of 28% ammonia water and anhydrous ethanol are mixed in a volume ratio of 1: 3.5: 4, and the mixed dispersion is prepared.

[0050] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com