Stirring heating device capable of tracking maximum wind energy utilization rate

A utilization rate and heating device technology, which is applied in the field of stirring heating devices, can solve the problems of reduced wind energy utilization efficiency, deviation of operation performance, and poor self-starting performance, so as to improve wind energy utilization efficiency, improve space utilization, and improve operation reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

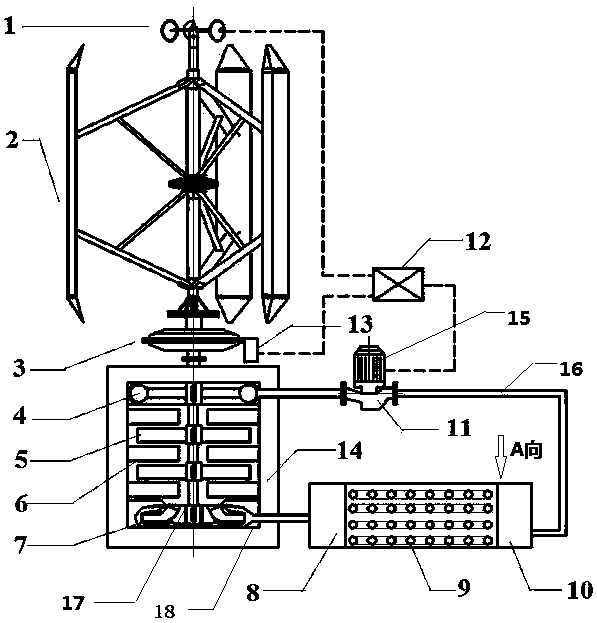

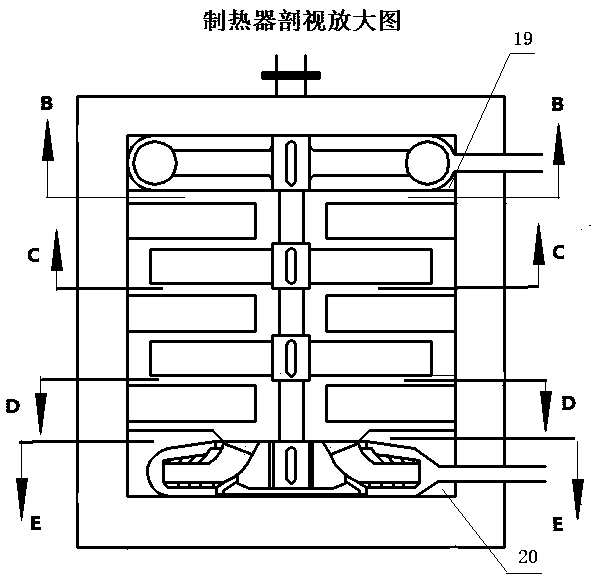

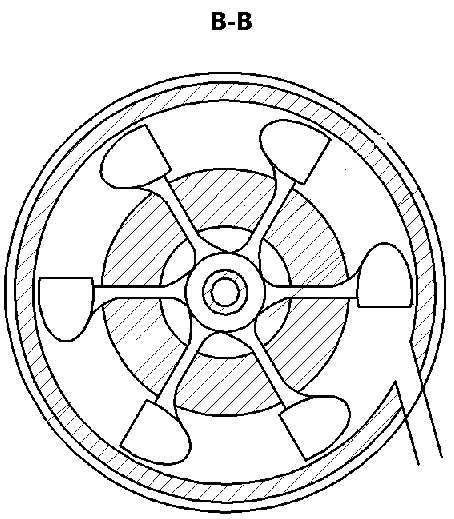

[0036] The following combination Figure 1-Figure 8 The present invention will be further described in detail with specific examples, and the specific examples described here are only used to explain the present invention, and are not intended to limit the present invention.

[0037] refer to Figure 1-Figure 8, a stirring and heating device for tracking the maximum utilization rate of wind energy according to the present invention, the wind cup type wind speed sensor 1 is installed on the top of the lift-type H-type vertical-axis wind turbine 2, and the lower end of the lift-type H-type vertical-axis wind turbine 2 is fixed Connected to the upper end of the planetary gear box 3, the planetary gear box 3 is a speed change mechanism, the output shaft of the lift-type H-type vertical axis wind turbine 2 is connected to the input shaft of the planetary gear box 3, and the laser speed sensor 13 is fixedly connected to the planetary box 3 , the lower end of the planetary gear box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com