Soil pressure balance model tunnel boring machine capable of realizing lining support function

An earth pressure balance and shield machine technology, which is applied in the field of shield machine testing, can solve the problem that the stratum conditions have a great influence and cannot realize the support function of the shield construction segment. Many scholars inside and outside have studied the model shield machine testing machine. Such as the small shield machine developed by Nomoto (1999) and others that can carry out centrifugal test, the small model shield machine suitable for clay established by Champan (2006) and others, and the small shield machine developed by the domestic Shanghai Tunnel Co., Ltd. (1996). Shield simulation test bench, large-diameter model shield machine developed by Shanghai Tunnel Co., Ltd. in cooperation with Zhejiang University and Tongji University (2004), double-shell single-helix model shield developed by Tongji University (2006), Beijing Jiaotong University (2007) ), the earth pressure balance shield machine developed by He Chuan (2013), the small-diameter mud-water balance shield developed by Shandong University (2016), etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

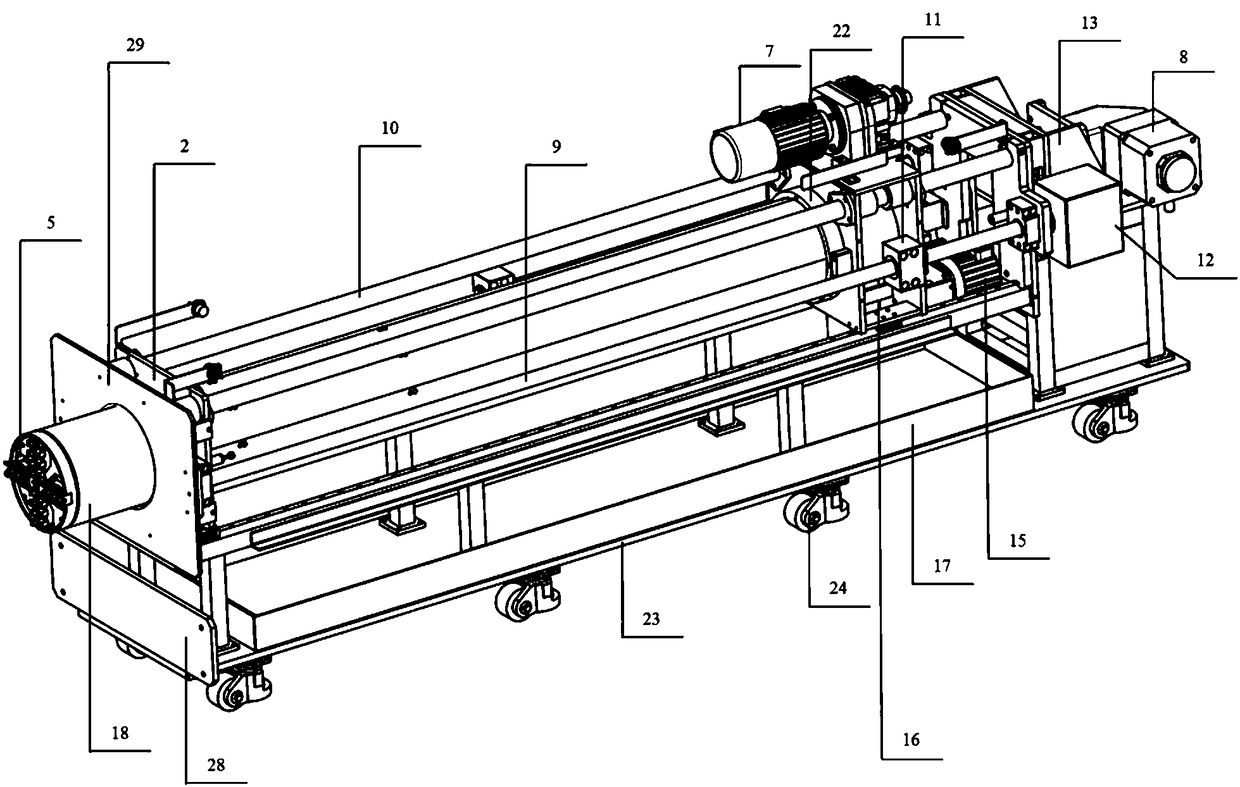

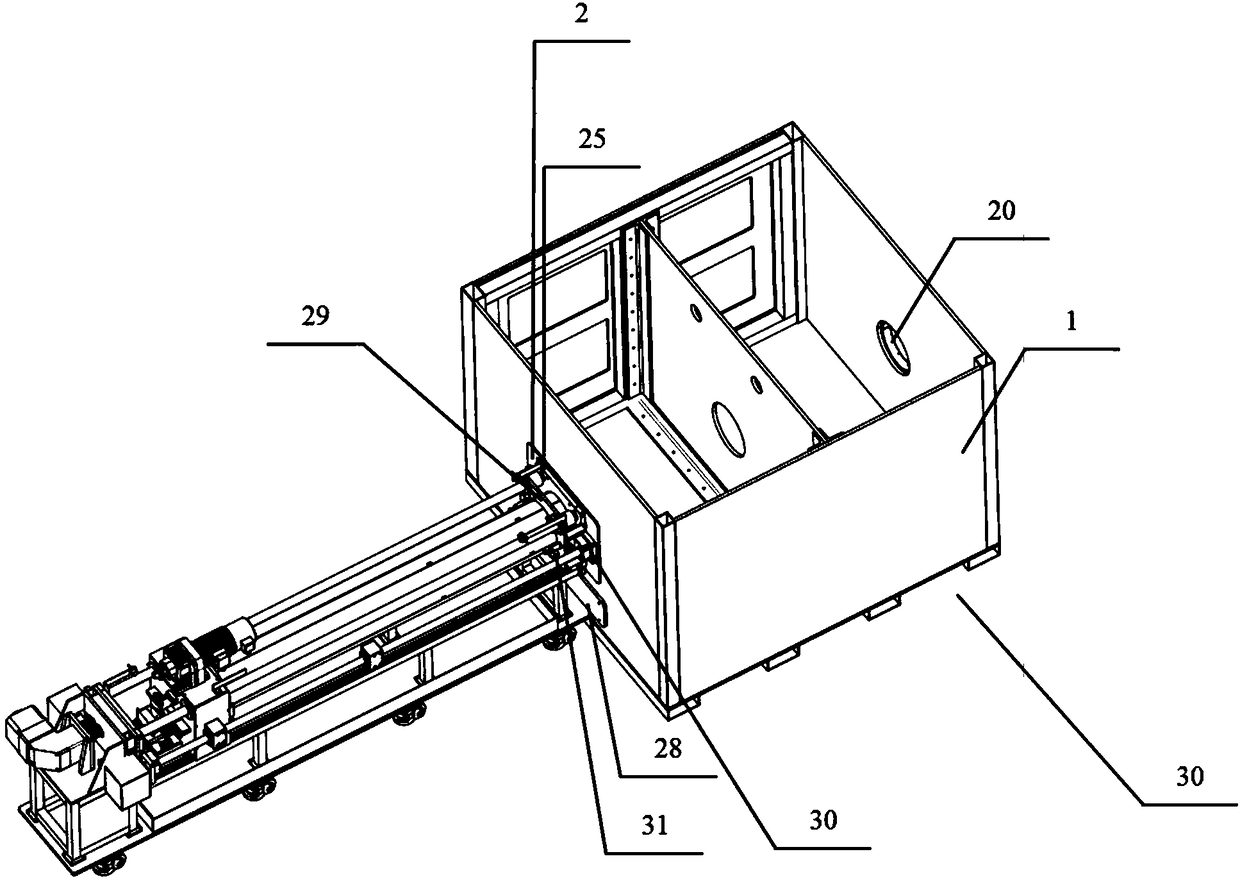

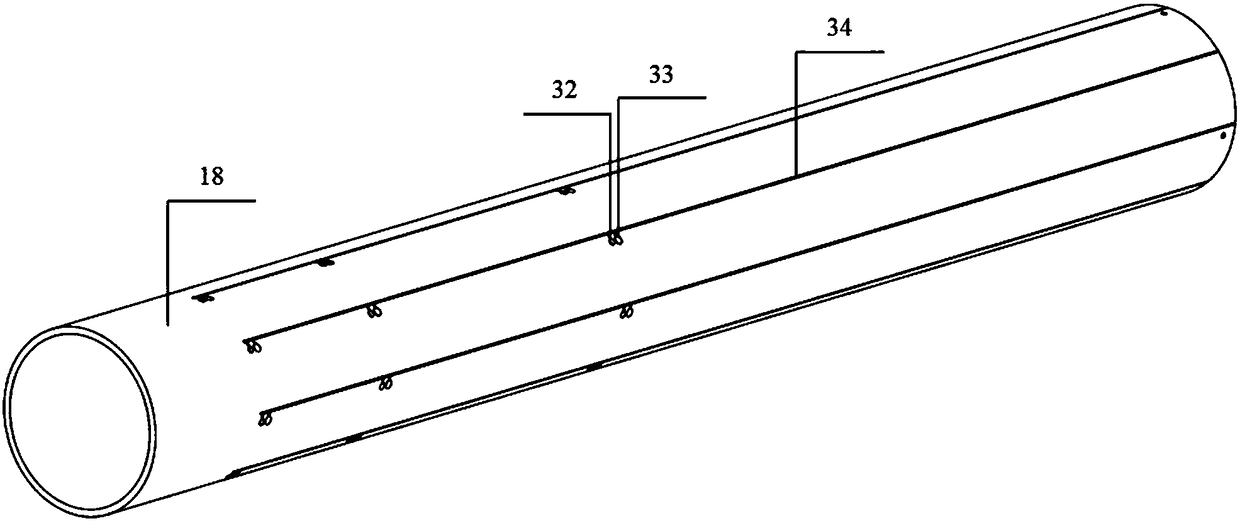

[0027] Such as Figure 1 to Figure 5 As shown, the earth pressure balance model shield testing machine of the present invention that can realize the lining support function includes a model box, a shield shell, a cutting system, a jacking system, an excavation system and a support system.

[0028]After fixing the model box (1) at the designated position for the test, make the universal wheels (24) of the shield machine base (23) touch the ground, move the shield machine to the matching position, and then make the supporting feet (24) touch the ground. The height of the supporting feet (24) keeps the base of the shield machine (23) and the base of the model box (1) on the same level. The shield machine and the model box (1) are connected together by connecting the shield machine base connecting plate (28) and the floating support connecting plate (39).

[0029] Befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com