Micro-grain light emitting diode display panel

A technology of light-emitting diodes and display panels, applied to static indicators, identification devices, instruments, etc., can solve the problems of loss of light energy, display devices are difficult to be thin and flexible, and increase the power consumption of liquid crystal display devices, etc., to achieve increased The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

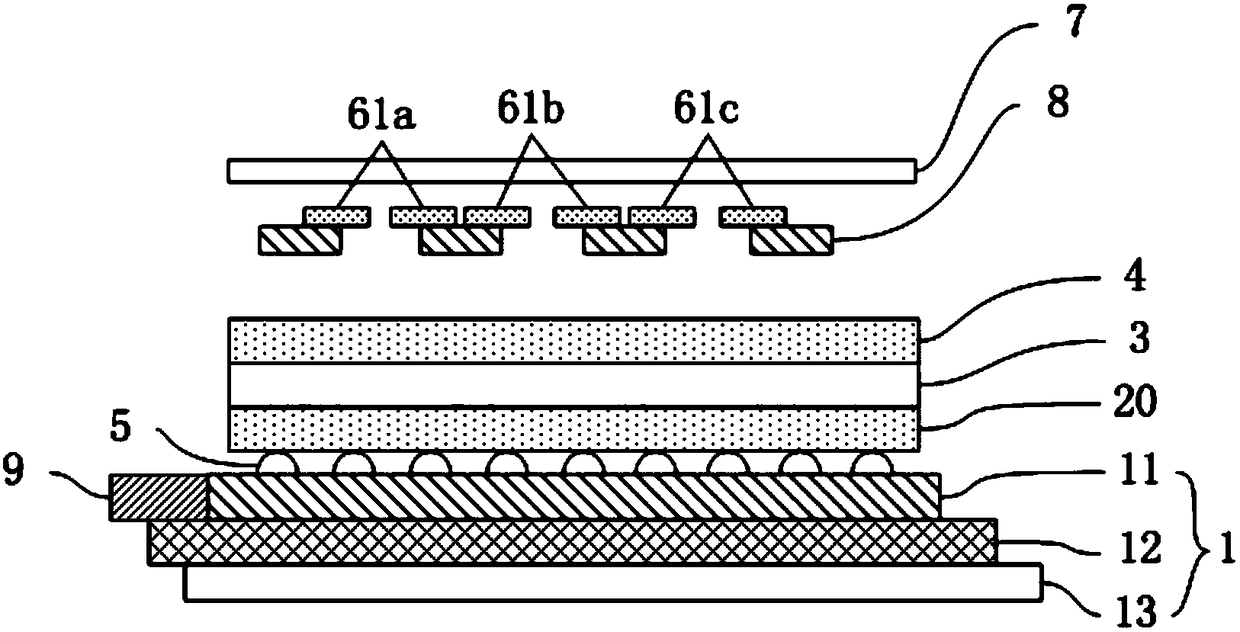

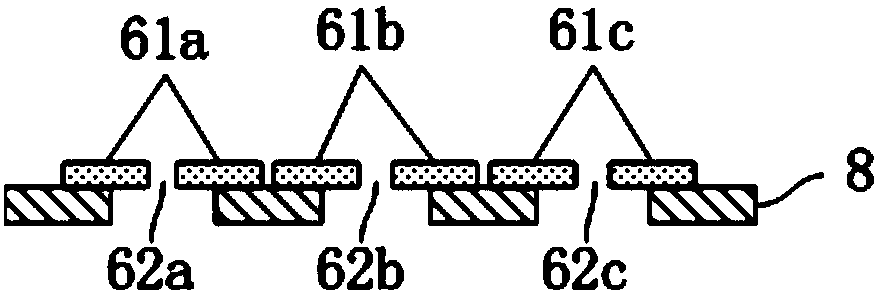

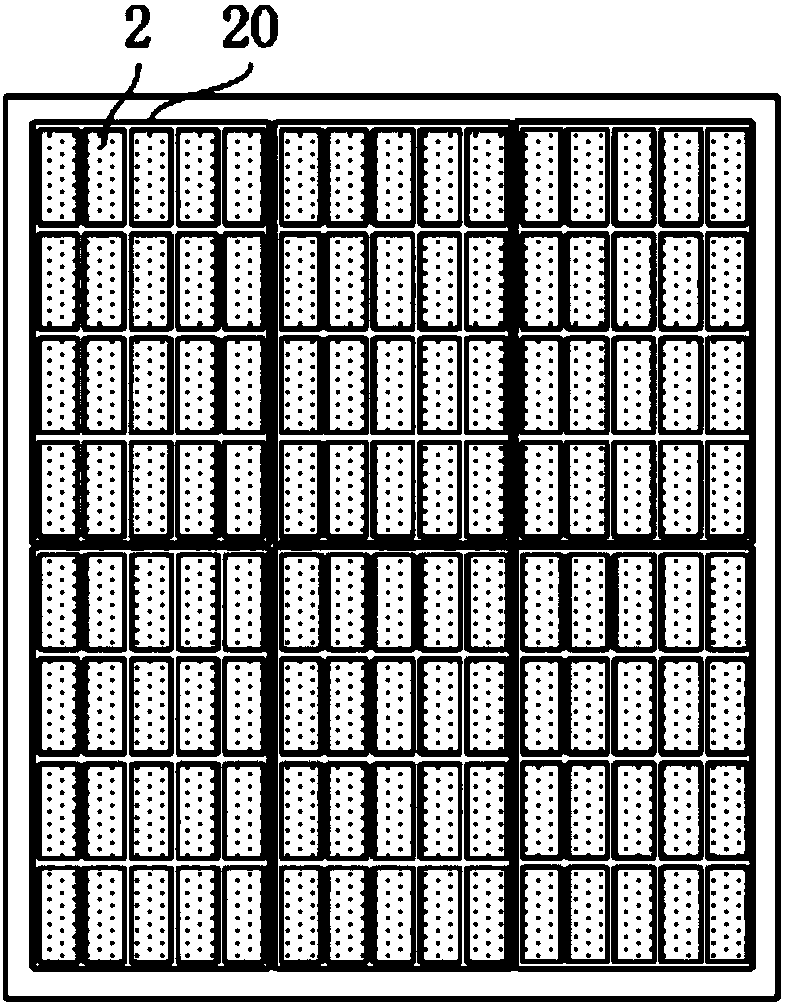

[0027] The present invention provides a microcrystalline light-emitting diode 2 display panel, such as figure 1 As shown, the display panel includes a flexible substrate 1, a plurality of light emitting diodes 2 arranged in an array, a diffraction grating 3 located above the plurality of light emitting diodes 2, a light scattering film 4, and a plurality of light valves located above the light scattering film 4, figure 1 61a, 61b, 61c shown in are light valves. Such as figure 2 As shown, the corresponding openings of the light valves 61a, 61b, and 61c are respectively 62a, 62b, and 62c.

[0028] Wherein, the flexible substrate 1 includes a driving circuit 11, and a plurality of light emitting diodes 2 are fixed on the flexible substrate 1 by flip-chip; white light.

[0029] The diffraction grating 3 is used to split the white light emitted by the light emitting diode 2 to form multiple outgoing lights with different wavelengths.

[0030] The light scattering film 4 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com