A kind of mesoporous composite molecular sieve, catalyst and its preparation method and application

A composite molecular sieve and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unproposed solutions, achieve uniform distribution of mesopore channels, low precious metal content, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] A preparation method of USY / MCM-48 mesoporous composite molecular sieve, the preparation method comprises the following steps:

[0065] Mix the USY molecular sieve and the alkali source in the aqueous solution to obtain the first solution;

[0066] dissolving the templating agent in water to obtain a second solution;

[0067] mixing the first solution and the second solution, adjusting the pH to 7-12 to obtain a third solution;

[0068] adding a silicon source to the third solution for crystallization;

[0069] The crystallized product is filtered, washed, dried and roasted to obtain USY / MCM-48 mesoporous composite molecular sieve.

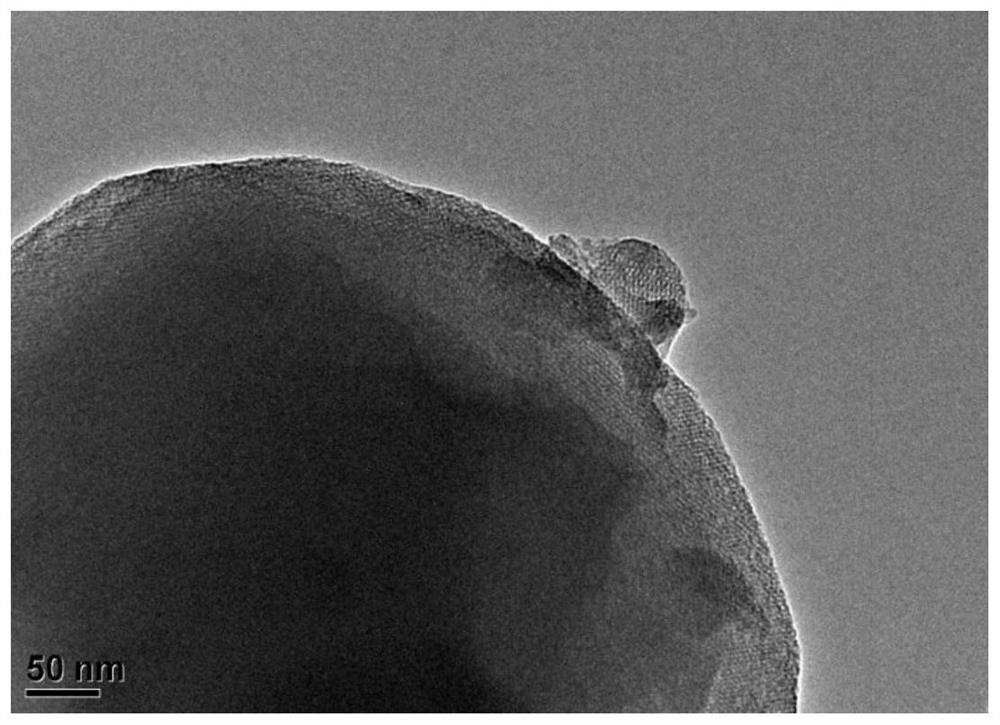

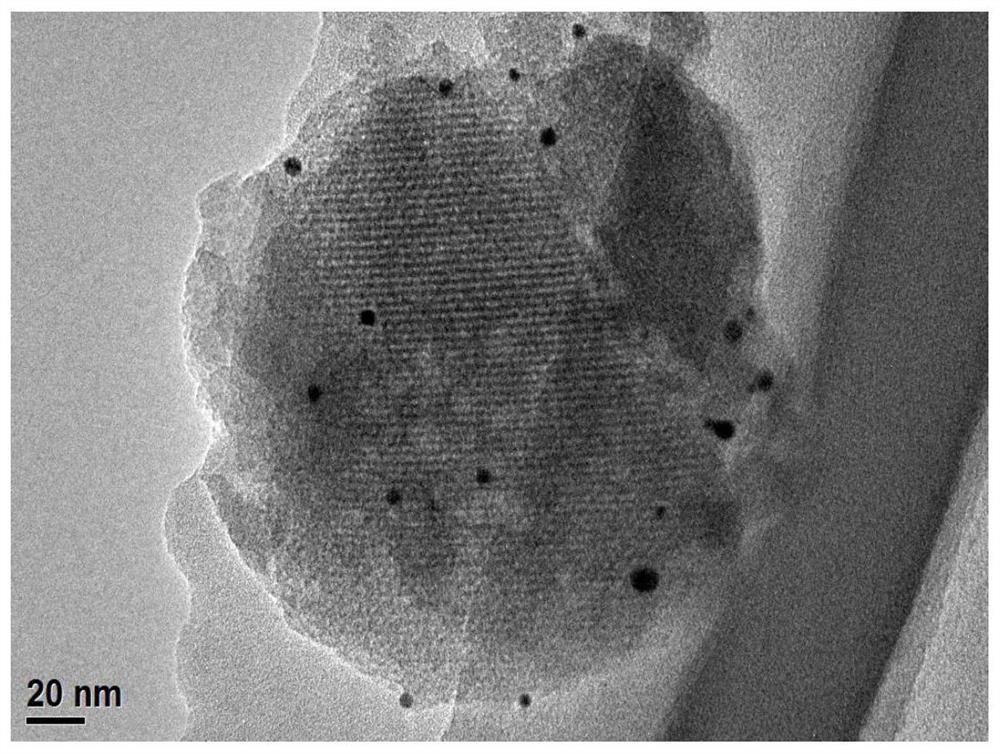

[0070] In this preparation method, the surface is covered with a layer of MCM-48 particles by using USY as the core, so that the combination of the two phases is tighter.

[0071] At the same time, the ratio of the microporous phase to the mesoporous phase in the mesoporous carrier can be controlled by adding different masses of USY micr...

Embodiment 1

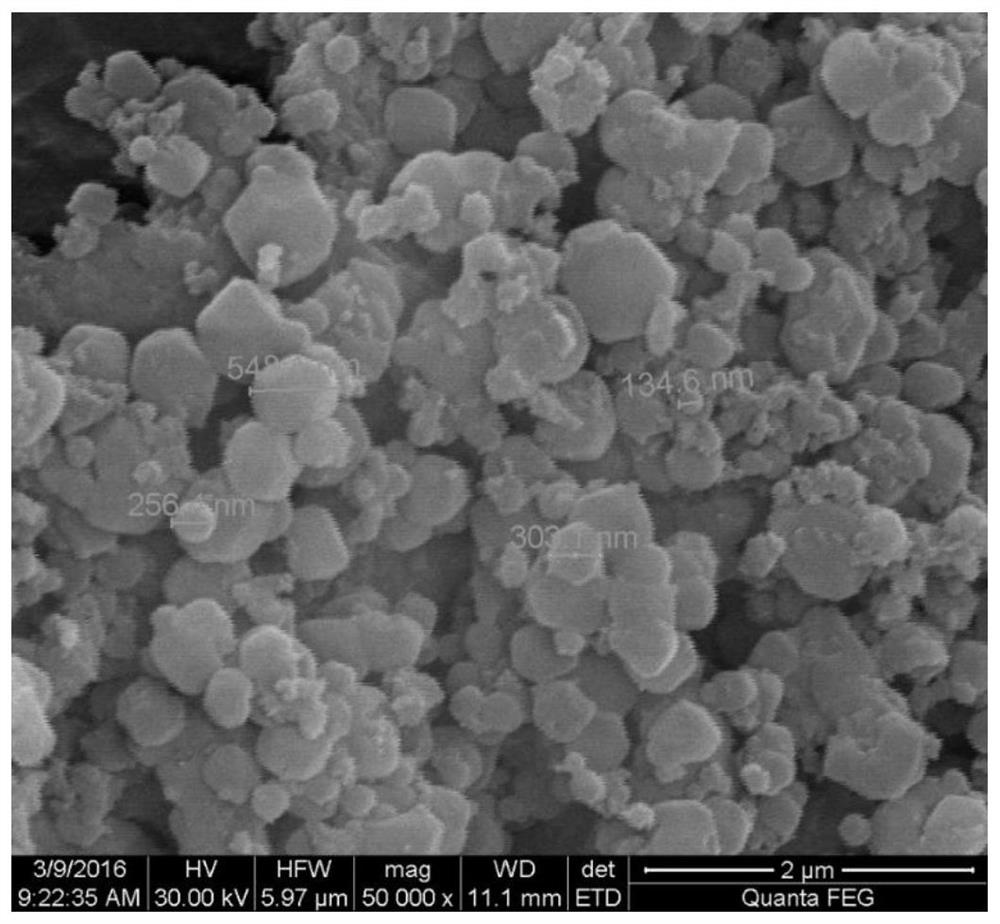

[0096] A USY / MCM-48 mesoporous composite molecular sieve, with mesoporous and microporous channel structure, mesopore pore size distribution is 2.0-4.0nm, micropore pore size distribution is 0.4-1.0nm; specific surface area is 1000-1200m 2 / g, the total pore volume is 1.0~1.2cm 3 / g, the mesopore volume accounts for 80-90% of the total pore volume.

[0097] The preparation method of above-mentioned USY / MCM-48 composite molecular sieve is as follows:

[0098] First dissolve 6g of NaOH in 60mL of water, then add 0.5g of dry USY molecular sieve powder into it, and stir in a water bath at 35°C for 1 hour to form the USY molecular sieve precursor;

[0099] Dissolve 4g CTAB and 7g P123 template in 80mL distilled water, stir at 35°C for 1 hour to form a transparent solution, and adjust the pH of the solution to 10 with ammonia water;

[0100] Add the USY molecular sieve precursor solution into the template solution, and stir for 2 hours. Then add 24g of TEOS dropwise to the mixed ...

Embodiment 2

[0103] A USY / MCM-48 mesoporous composite molecular sieve, with mesoporous and microporous channel structure, mesopore pore size distribution is 2.0-4.0nm, micropore pore size distribution is 0.4-1.0nm; specific surface area is 1000-1200m 2 / g, the total pore volume is 0.8~1.0cm 3 / g, the mesopore volume accounts for 70-80% of the total pore volume.

[0104] The preparation method of above-mentioned USY / MCM-48 composite molecular sieve is as follows:

[0105] Firstly, 6g of NaOH was dissolved in 60mL of water, then 1g of dry USY molecular sieve powder was added to it, and stirred in a water bath at 35°C for 1 hour to form a USY molecular sieve precursor;

[0106] Dissolve 4g of CTAB and 7g of P123 template in 80mL of distilled water, stir at 35°C for 1 hour to form a transparent solution, and adjust the pH of the solution to 10 with ammonia water; add USY molecular sieve precursor to the template solution, and stir for 2 hours;

[0107] Then, 18g TEOS was added dropwise into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com