Specialized process mold for machining pi-ring sealing washer and manufacturing and use method

A ring seal and gasket technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inability to solve deformation and precision, high expansion coefficient, processing difficulties, etc., to shorten the production cycle, simple production, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described in conjunction with accompanying drawing now:

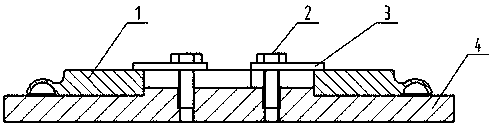

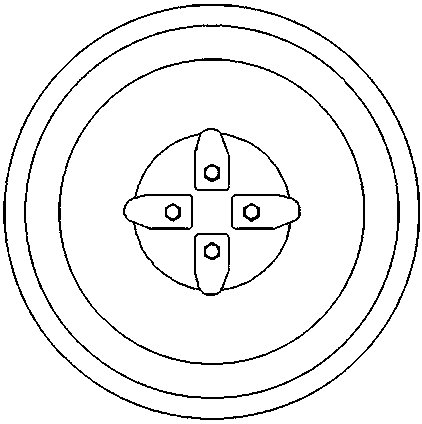

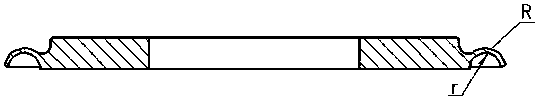

[0024] Special process mold for processing Ω ring sealing gasket: such as Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the special process mold for processing Ω-ring sealing gaskets: the mold structure includes a second-order circular platform, bolts and pressure plates. The height of the table is 7mm, the diameter of the boss is 3-15μm smaller than the actual size of the inner diameter of the Ω ring sealing gasket, four bolt holes are evenly distributed on the boss, and the diameter is M12-20; the pressure plate is rectangular, and the end of the presser foot is a pointed circle Angle, slope shape, there are holes in the pressure plate, the diameter is slightly larger than the diameter of the bolt. The mold material is steel plate.

[0025] The manufacturing method of the special craft mold for processing the omega ring sealing gask...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com