Building engineering plastic recycling crushing device

A plastic recycling and crushing device technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of uneven crushing, engineering plastics that cannot be crushed in long strips, and simple structure, so as to improve crushing efficiency, The effect of uniform force and lightening the burden on workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

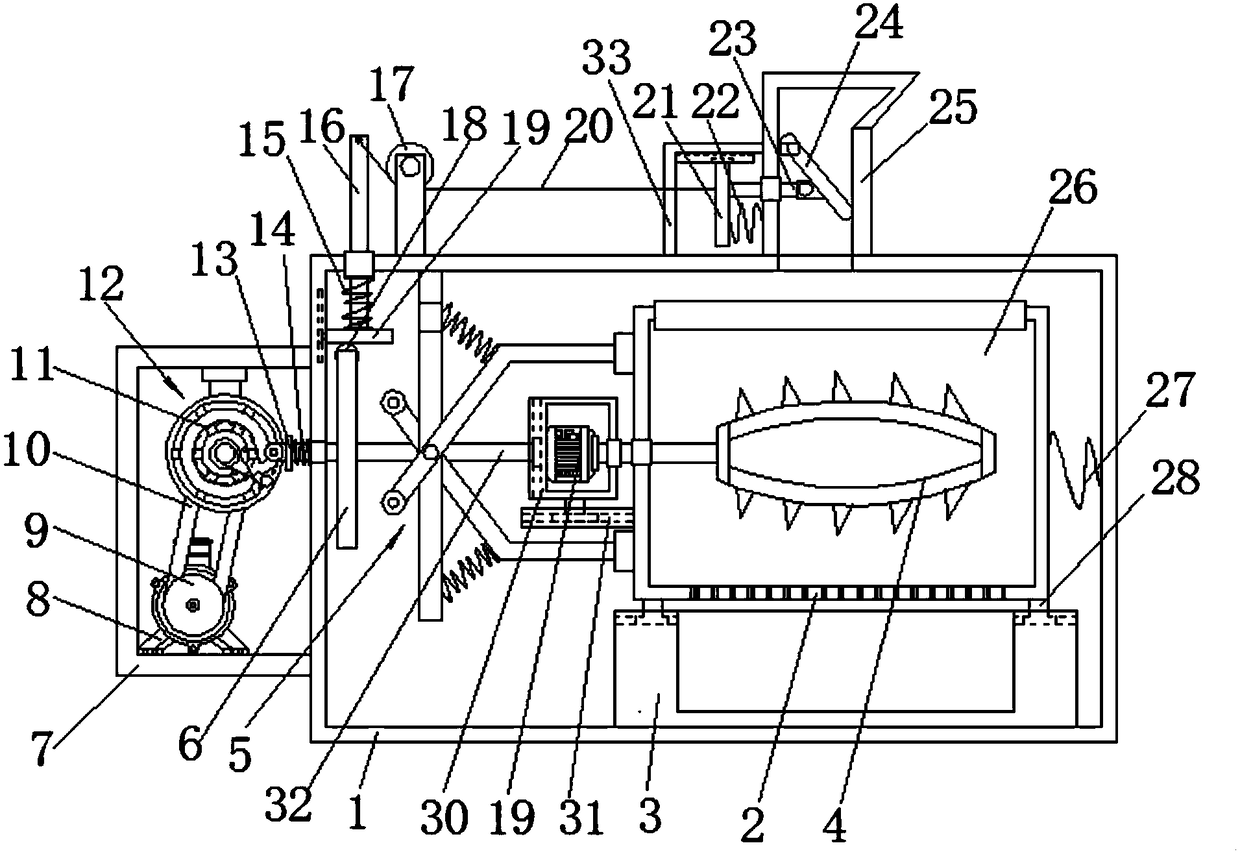

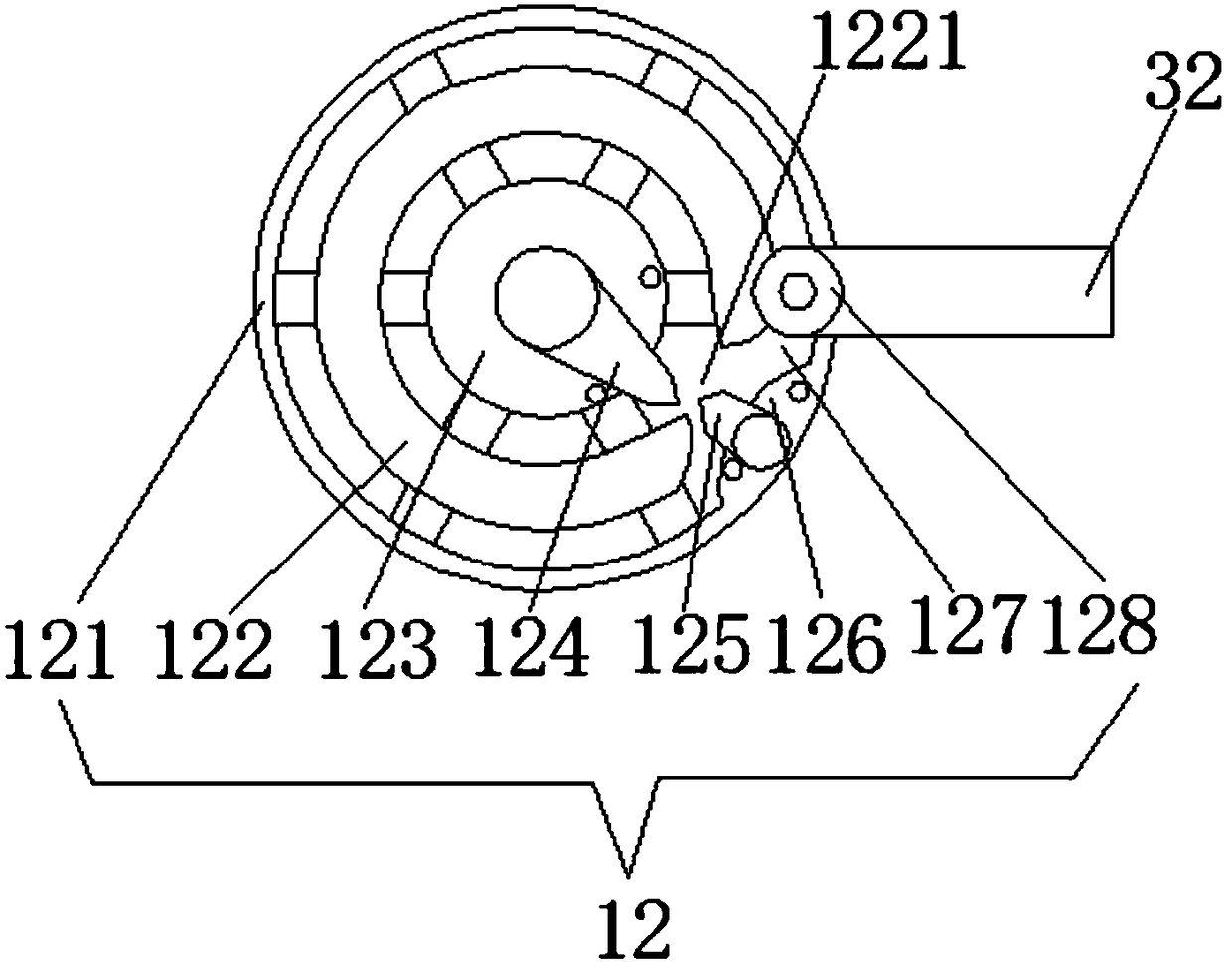

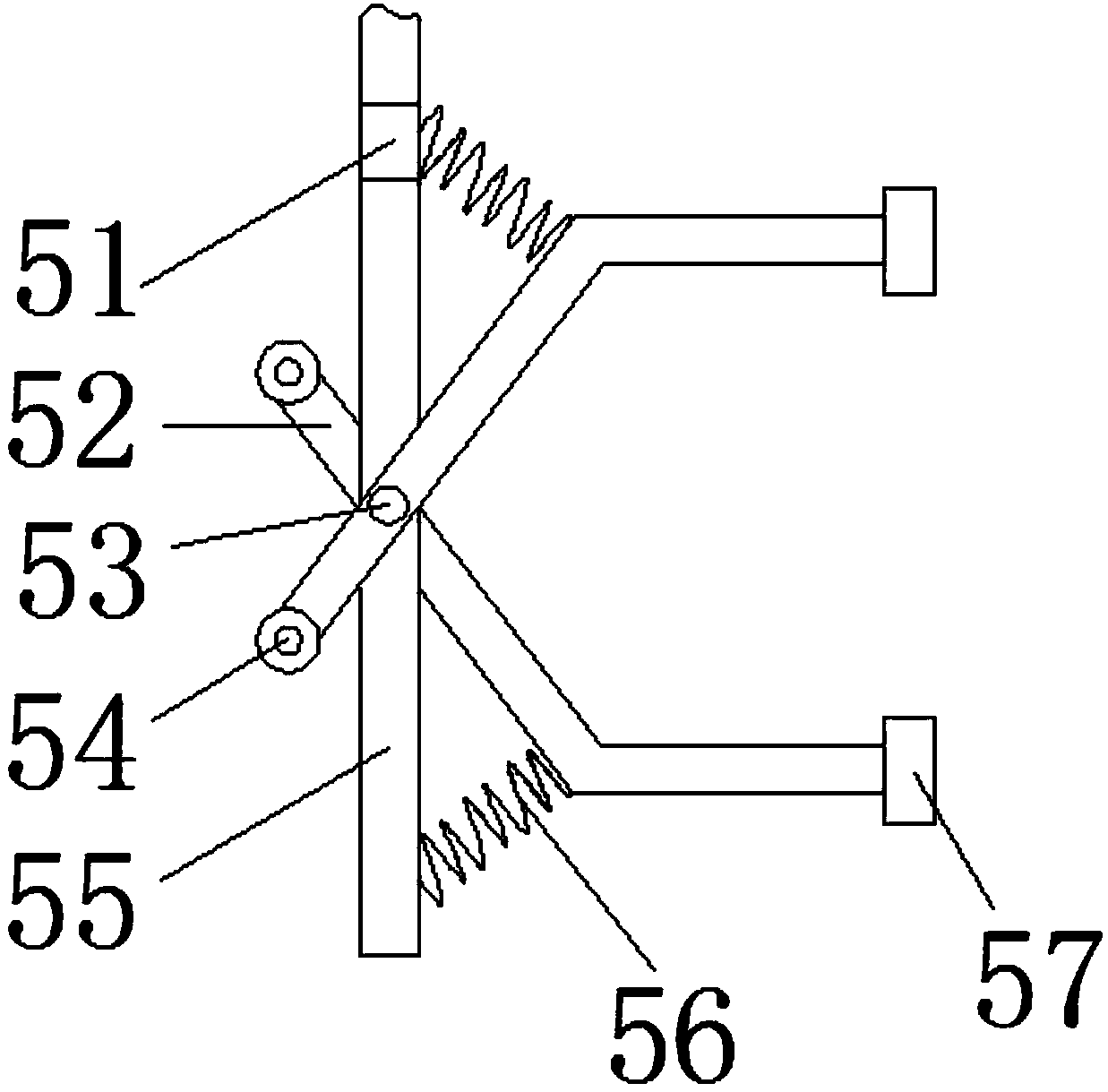

[0025] see Figure 1-3 , the present invention provides a technical solution: a recycling and crushing device for construction engineering plastics, comprising an outer frame 1 of the device, a crushing box 26 arranged inside the outer frame 1 of the device, a feed channel 25 arranged at the top of the outer frame 1 of the device, and Be located at the feed box 3 of crushing box 26 below. This pulverizing box 26 inside is provided with pulverizing wheel 4, and the left side of pulverizing box 26 is equipped with second power box 30, and second power box 30 inside is fixedly installed with second motor 19, and the output shaft of second motor 19 penetrates pulverizing box 26 The inside is fixed with the crushing wheel 4; the bottom of the crushing box 26 is provided with a leak hole 2, and the plastic crushed by the crushing wheel 4 enters the material box 3 through the leak hole 2. Crushing box 26 left sides are also equipped with vibrating hammer device 5, and vibrating hamm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com