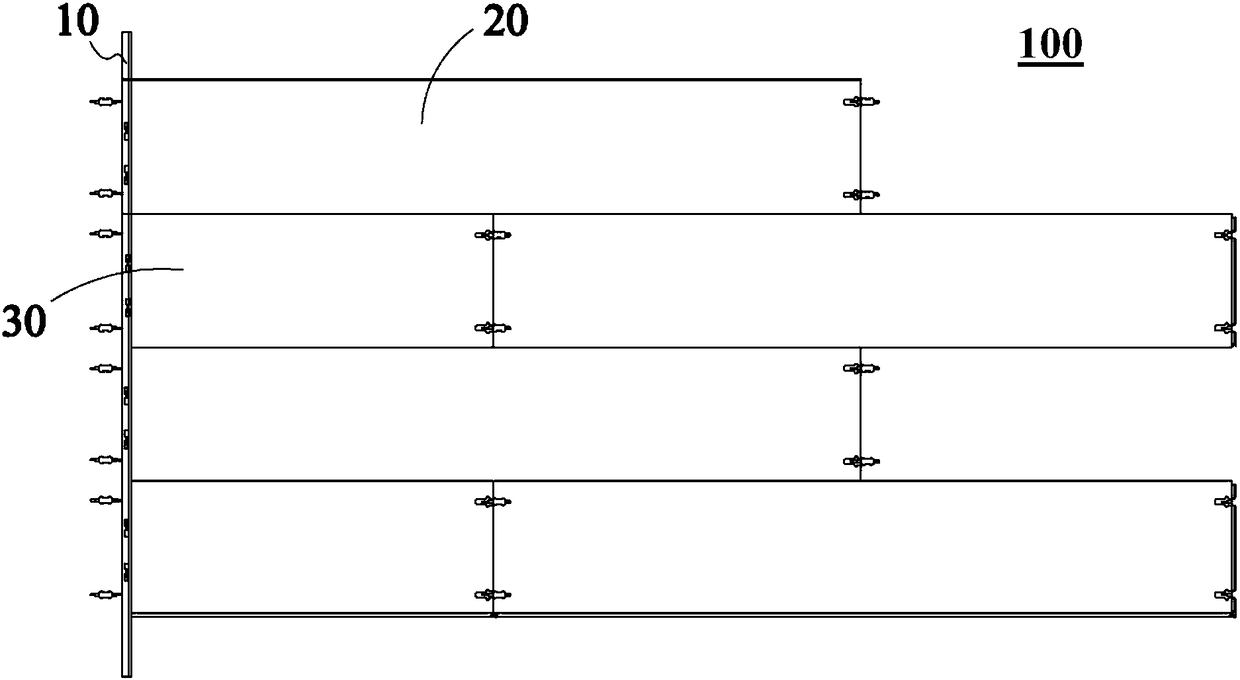

Self-heating floor and self-heating floor system thereof

A self-heating and flooring technology, which is applied in the direction of electric heating system, heating system, household heating, etc., can solve the problems of uneven ground, non-heating of the floor, and inability to lay in large areas, so as to achieve paving operations suitable for large areas , Improve the effect of paving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

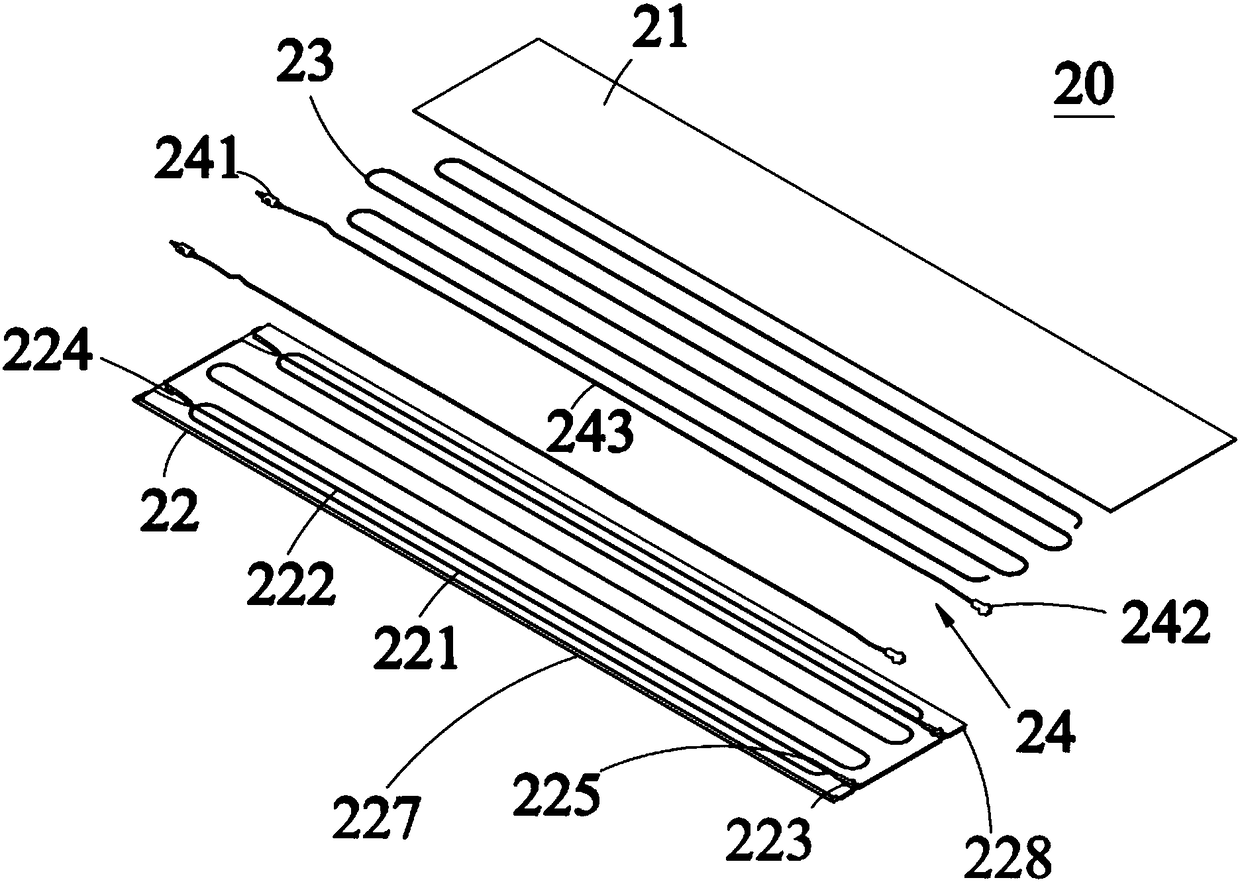

[0043] ginseng figure 2As shown, this embodiment discloses a self-heating floor 20, including: a bottom plate 22 and a top plate 21 that are laminated and bonded, a heating cable 23 coiled between the bottom plate 22 and the top plate 21, and an even number of electrically connected heating elements. Electrical connector 24 for cable 23 . Specifically, the bottom plate 22 and the top plate 21 are made of PVC, wood plastic, stone plastic or solid wood. In this implementation, the bottom plate 22 is made of PVC, and the top plate 21 is made of solid wood.

[0044] Specifically, in this embodiment, the diameter of the heating cable 23 can be 1-6mm, and the heating power is set at 150-350W / M 2 . A plurality of heating cables 23 can be connected in parallel through an electrical connector 24, and a plurality of heating cables 23 in two adjacent rows of self-generating heating floors 20 can be connected in parallel through an electrical connector 24, and simultaneously connected...

Embodiment 2

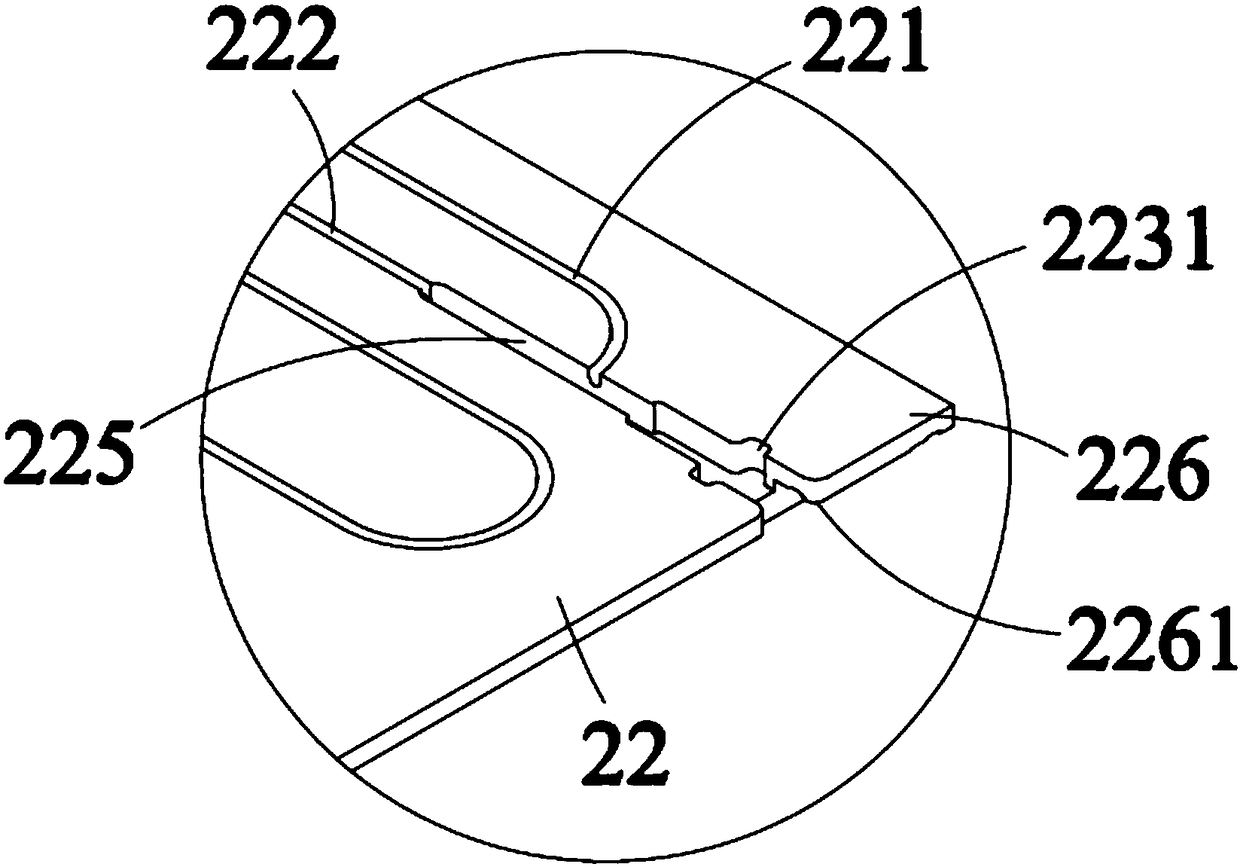

[0062] This embodiment shows a first modified example of a self-heating floor 20. Compared with Embodiment 1, the main difference is that, in this embodiment, the surface of the bottom plate 22 facing the top plate 21 forms a completely accommodating heating cable 23 The first receiving groove 221 of the electrical connector 24 and the second receiving groove 222 that completely accommodate the electrical connector 24, and the two ends of the second receiving groove 222 respectively form a first expansion that completely accommodates the terminals at the two ends of the electrical connector 24. The recessed portion 224 and the second expanded recessed portion 223 . Wherein, the female terminal 242 is completely accommodated in the second expanded concave portion 223 , the male terminal 241 is completely accommodated in the first expanded concave portion 224 , and the upper plane 2424 of the female terminal 242 is flush with the upper surface of the bottom plate 20 At the same ...

Embodiment 3

[0065] This embodiment shows a second modification of the self-heating floor 20. Compared with Embodiment 1 and / or Embodiment 2, especially compared with Embodiment 2, the main difference is that in the embodiment The first receiving groove 221 and the second receiving groove 222 mentioned above are all formed on the bottom surface of the top plate 21, and the upper surface of the bottom plate 22 may not be provided with the first receiving groove 221 and the second receiving groove 222, so as to form a smooth surface.

[0066] For the technical solutions in this embodiment that are the same as those in Embodiment 1 and / or Embodiment 2, please refer to Embodiment 1, and details will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Heating power | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com