Method for testing electrical conductivity of graphene powder

A technology of graphene powder and bulk conductivity, which is applied in the preparation of test samples, measuring devices, and material analysis through electromagnetic means, which can solve the problems that affect the accuracy of graphene conductivity test results, unevenness of graphene surface, Graphene powder is not easy to form into sheets, etc., to achieve good compression molding, simple steps, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

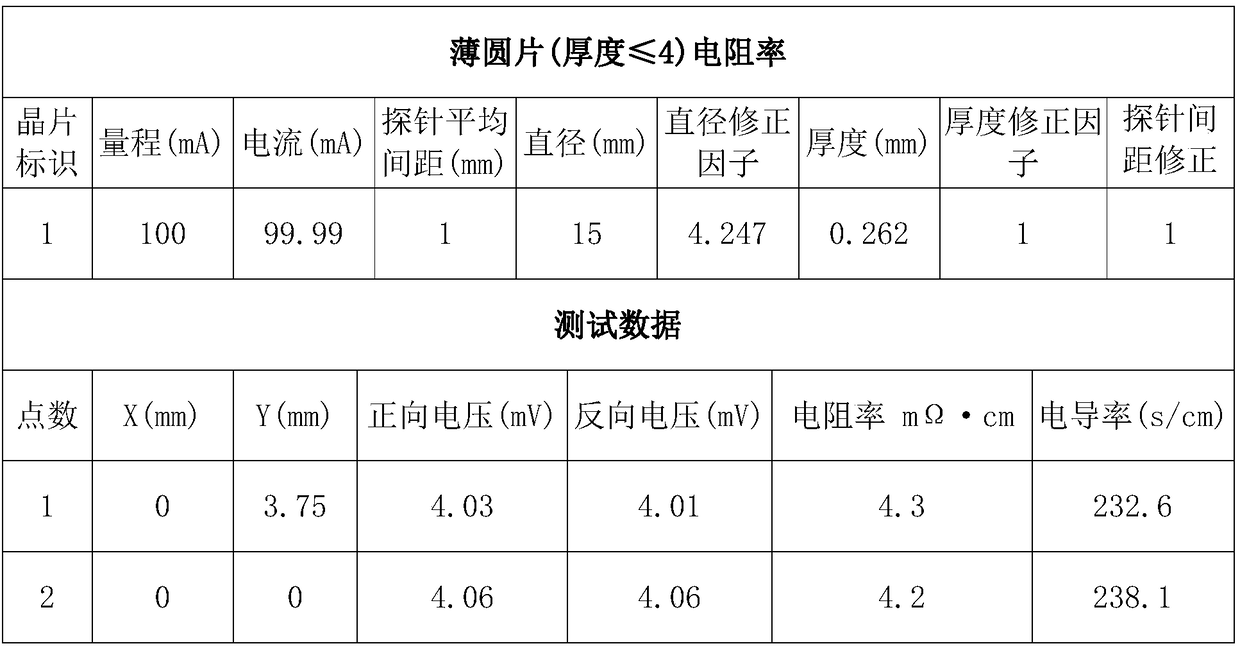

[0075] Weigh 48 mg of graphene powder and 12 mg of PVDF and grind them evenly in a mortar, prepare an aluminum foil with a thickness of 15 μm that is suitable for the sheet-making mold, spread the aluminum foil on the bottom of the mold, pour the ground sample into the mold, and cover the upper layer as well Aluminum foil, adjust the tablet press to a pressure of 25 MPa for tableting, and keep the pressure for 30 minutes; take out the graphene sheet, and tear off the aluminum foil attached to its surface, and use an electronic digital display outer diameter micrometer to measure different positions of the tablet (take The thickness of the three points on the left, center, and right), and the conductivity of the three points on the left, center, and right are measured, and the average value is calculated as the conductivity of the graphene powder.

[0076] The conductivity test results are shown in Table 1 below.

[0077] Table 1

[0078]

[0079]

Embodiment 2

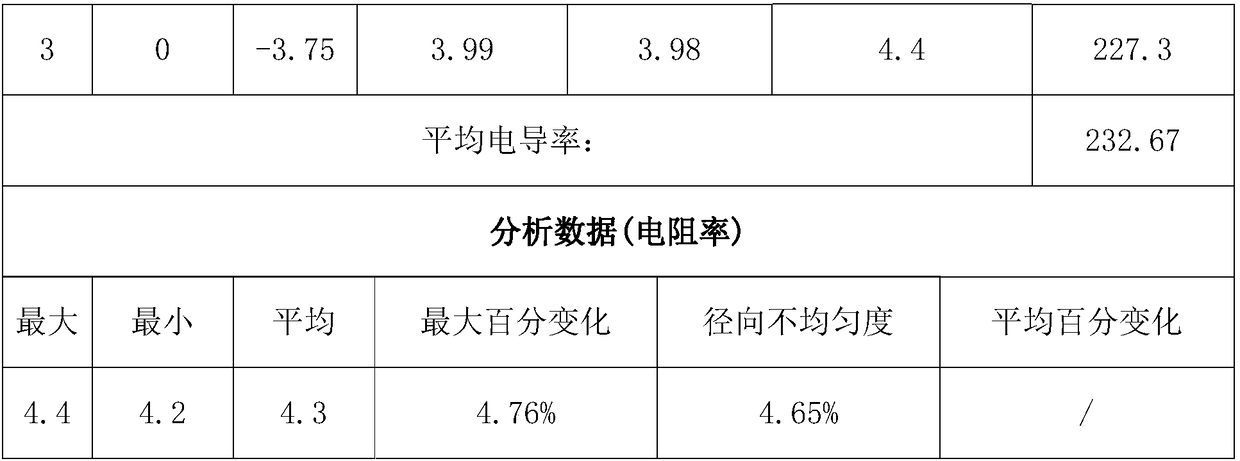

[0081] Weigh 48mg of graphene powder and 12mg of PVP and grind them evenly in a mortar; prepare an aluminum foil with a thickness of 15μm that is suitable for the sheet-making mold, spread the aluminum foil on the bottom of the mold, pour the ground sample into the mold, and cover the upper layer as well Aluminum foil, adjust the tablet press to a pressure of 25 MPa for tableting, and keep the pressure for 30 minutes; take out the graphene sheet, and tear off the aluminum foil attached to its surface, and use an electronic digital display outer diameter micrometer to measure different positions of the tablet (take The thickness of the three points on the left, center, and right), and the conductivity of the three points on the left, center, and right are measured, and the average value is calculated as the conductivity of the graphene powder.

[0082] The conductivity test results are shown in Table 2 below.

[0083] Table 2

[0084]

[0085]

Embodiment 3

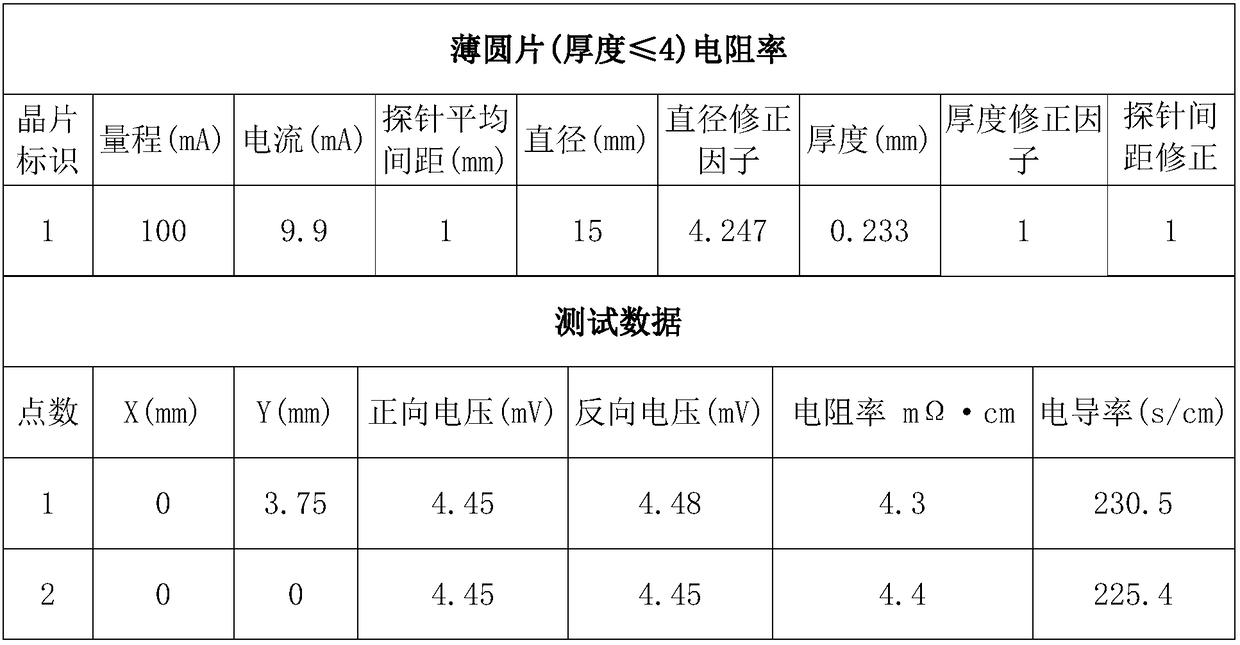

[0087] Weigh 48mg of graphene powder and 24mg of PVDF and grind them evenly in a mortar; prepare an aluminum foil with a thickness of 15μm that is suitable for the tablet-making mold, spread the aluminum foil on the bottom of the mold, pour the ground sample into the mold, and cover the upper layer as well Aluminum foil, adjust the tablet press to a pressure of 25 MPa for tableting, and keep the pressure for 30 minutes; take out the graphene sheet, and tear off the aluminum foil attached to its surface, and use an electronic digital display outer diameter micrometer to measure different positions of the tablet (take The thickness of the three points on the left, center, and right), and the conductivity of the three points on the left, center, and right are measured, and the average value is calculated as the conductivity of the graphene powder.

[0088] The conductivity test results are shown in Table 3 below.

[0089] table 3

[0090]

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com