A method for ultrasonically preparing stable gel-like wheat prolamin pickering emulsion

A wheat gliadin and alcohol solution technology, which is applied in the fields of food science, food preservation, application, etc., can solve the problems of unstable long-term storage, etc., and achieve the effect of high stability and strong application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method for wheat prolamin Pickering emulsion, comprising the following steps:

[0042] (1) Dissolve 1g of wheat prolamin in 40ml of 70% ethanol solution; get 100ml of 1% acetic acid solution, and pour the alcoholic solution of wheat prolamin into it while homogenizing, and the number of revolutions is 6000rpm , 4min;

[0043] (2) The solution obtained in step (1) was rotary evaporated, the vacuum degree was 0.1Mpa, and the temperature was controlled at 40°C for 20min;

[0044] (3) Take 5ml of the solution obtained in step (3), add 5ml of corn oil, and cut for 2min at 3000rpm;

[0045] (4) The emulsion that step (3) obtains is in power 0, 80W, 160W, 240W, 320W, 400W, accounts for total power 0, 20%, 40%, 60%, 80%, 100% respectively, and pulse is 70 % under the condition of sonication for 6 minutes to obtain wheat prolamin Pickering emulsion.

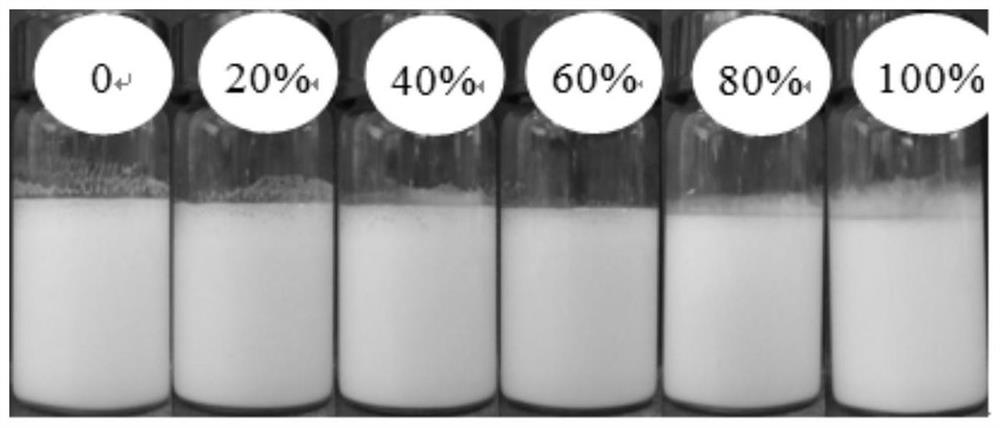

[0046] The appearance of the wheat prolamin Pickering emulsions obtained in step (4) with different ultrasonic p...

Embodiment 2

[0049] A preparation method for wheat prolamin Pickering emulsion, comprising the following steps:

[0050](1) 1g wheat prolamin is dissolved in 40ml 80% ethanol solution; Get 100ml 3% acetic acid solution, pour the alcoholic solution that is dissolved with wheat prolamin into it while homogenizing, and the rotating speed is 8000rpm, 5min;

[0051] (2) The solution obtained in step (1) was rotary evaporated, the vacuum degree was 0.1Mpa, and the temperature was controlled at 40°C for 20min;

[0052] (3) Take 5ml of the solution obtained in step (3), add 5ml of corn oil, and cut for 2min at 3000rpm;

[0053] (4) The emulsion that step (3) obtains is in power 0, 80W, 160W, 240W, 320W, 400W, respectively accounts for total power 0, 20%, 40%, 60%, 80%, 100%, pulse is 80 % under the condition of sonication for 5 minutes to obtain wheat prolamin Pickering emulsion.

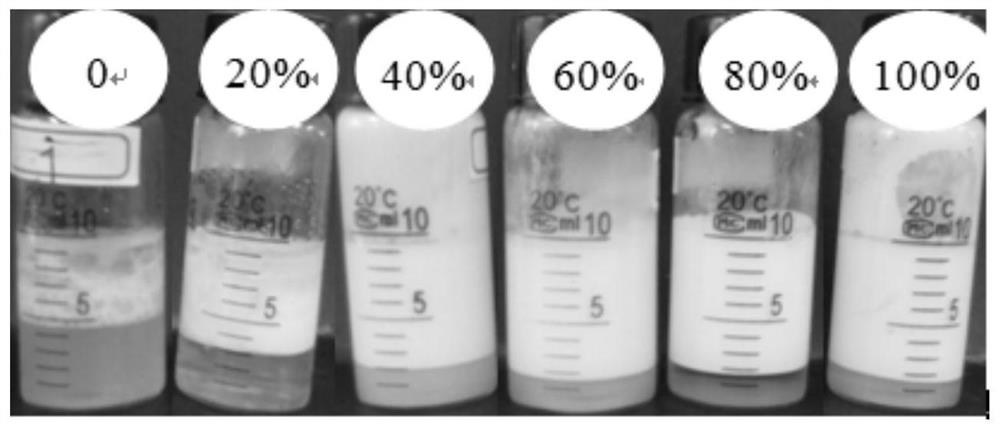

[0054] The particle sizes of wheat prolamin Pickering emulsions obtained with different ultrasonic powers are show...

Embodiment 3

[0061] A preparation method for wheat prolamin Pickering emulsion, comprising the following steps:

[0062] (1) Dissolve 1g of wheat prolamin in 50ml of 60% ethanol solution; get 100ml of 5% acetic acid solution, pour the alcoholic solution of wheat prolamin into it while homogenizing, and the number of revolutions is 6500rpm , 7min;

[0063] (2) The solution obtained in step (1) was rotary evaporated, the vacuum degree was 0.1Mpa, and the temperature was controlled at 40°C for 25min;

[0064] (3) Take 5ml of the solution obtained in step (3), add 5ml of corn oil, and cut for 90s at 4000rpm;

[0065] (4) Sonicate the emulsion obtained in step (3) for 6 minutes under the conditions of power of 0, 160W (accounting for 40% of total power) and pulse of 70%, to obtain wheat prolamin Pickering emulsion.

[0066] The ultrasonic power that step (4) obtains is that the new system emulsion of 0 and ultrasonic power are 160W, accounts for the microstructure of the emulsion of 40% of to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com