System for realizing three-state switching operation of thermoelectric unit

A three-state, thermoelectric unit technology, applied in mechanical equipment, steam engine installations, machines/engines, etc., to achieve the effect of small transformation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

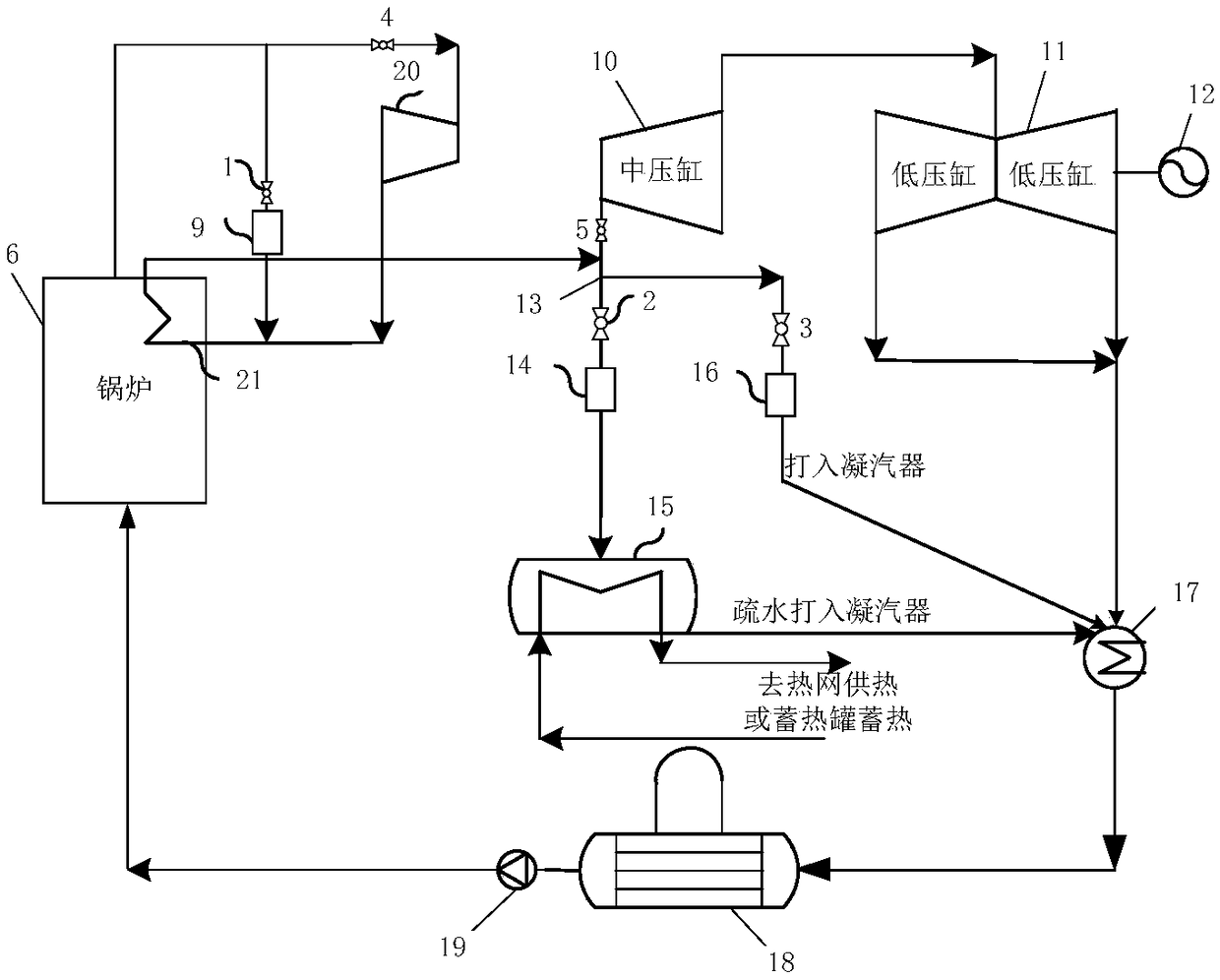

[0038] Embodiment 1 (single heating mode)

[0039] refer to figure 1 , a system that realizes the switching operation of the thermal power unit in three states, including the high-pressure bypass water spraying temperature reduction and pressure reduction pipeline, the low pressure bypass water spraying temperature reduction and pressure reduction pipeline, the heating network heater and the centralized control system of the power plant The bypass heating control module sends all the steam to the heat network heater for heat exchange through the high-pressure and low-pressure water spraying, temperature reduction and decompression bypass, which can realize that the steam turbine of the thermal power unit does not enter the steam at all, so that the cogeneration unit can be completely switched to become The single heating boiler operation mode supplies external heat.

[0040] Specifically, the boiler 6 is connected to the high-pressure cylinder 20, the boiler 6 is provided wit...

Embodiment 2

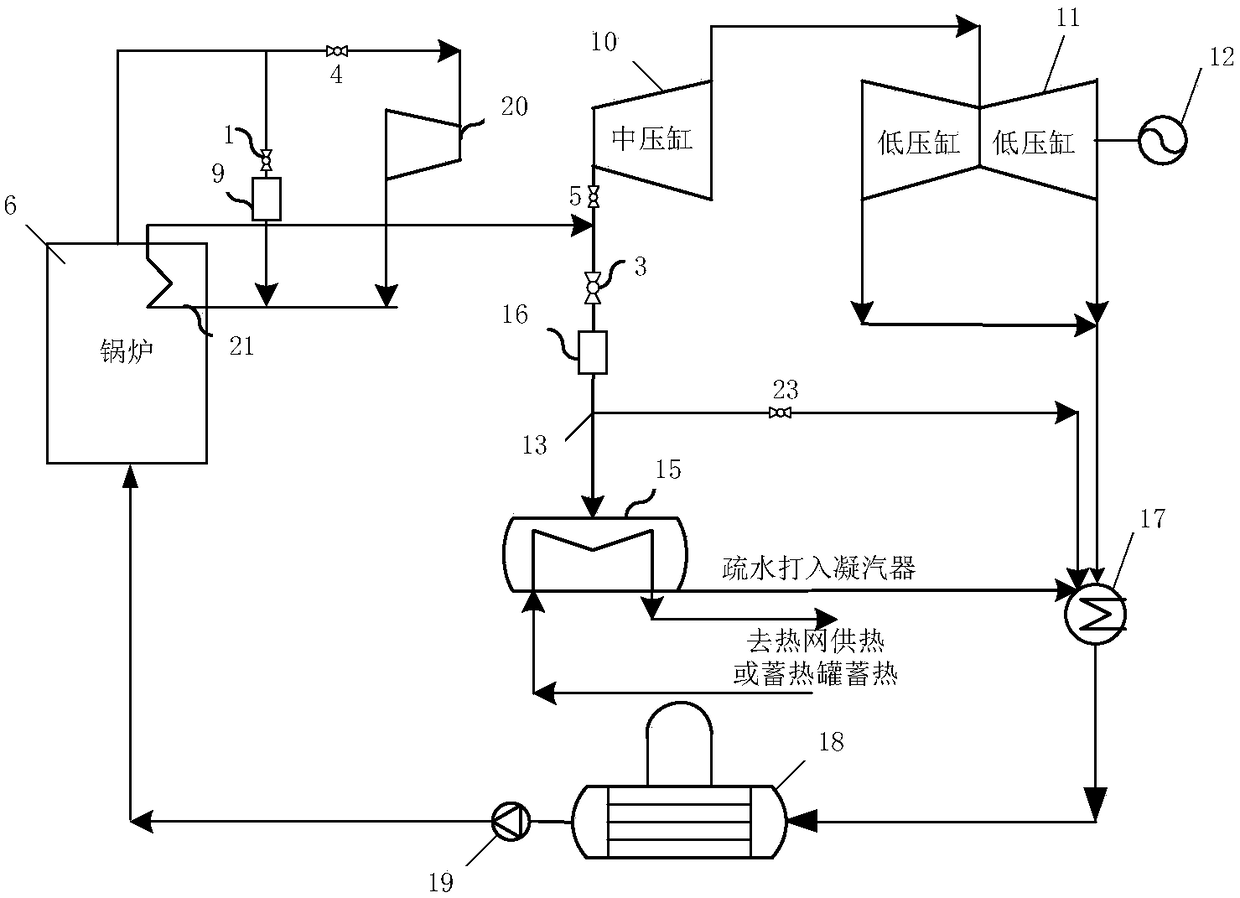

[0065] Embodiment 2 (single heating mode)

[0066] refer to figure 2 , the difference from Example 1 is that the low-pressure bypass water spray desuperheating and pressure reducing pipeline includes a low-pressure water spraying desuperheating and pressure reducing device 16 and a low-pressure inlet cut-off valve 23, and the low-pressure water spraying desuperheating and pressure reducing device A bypass regulating valve 3 is provided at the inlet of 16, and the hot network heater is connected in parallel with the inlet shut-off valve 23.

[0067] The low-pressure inlet stop valve 6 is set on the pipeline connected to the condenser, so that the existing two-stage bypass can be used to the greatest extent, so that the system modification cost is the lowest. However, such a connection method requires that the original Class I or Class II bypass flow should be large enough, on the one hand, it must meet the minimum cooling flow requirements of the reheater, and on the other ha...

Embodiment 3

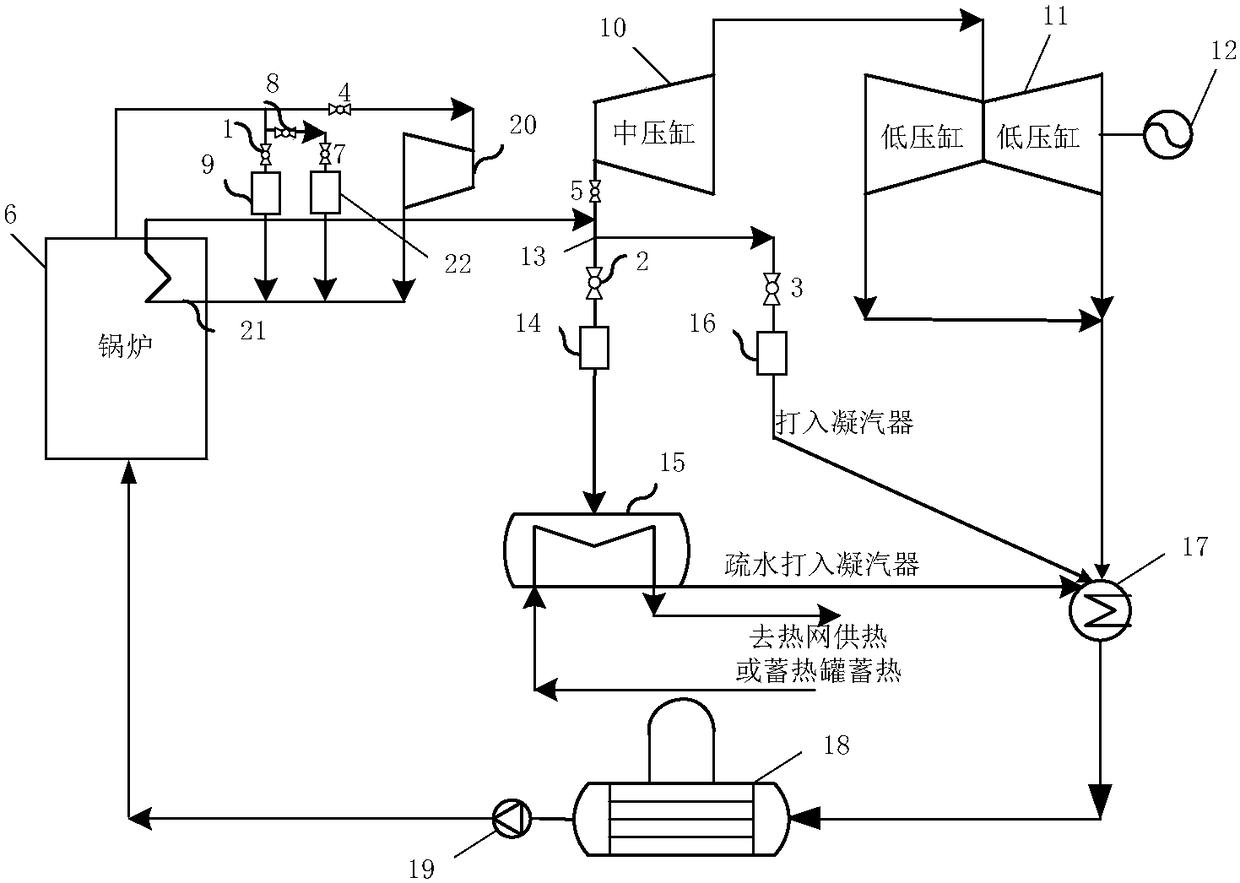

[0068] Embodiment 3 (single heating mode)

[0069] refer to image 3 , and embodiment 1 is different in that, between the boiler 6 and the high-pressure cylinder 20, there is also a large-flow high-pressure bypass water spraying temperature reduction and decompression pipeline, and the large-flow high-pressure bypass water spraying temperature reduction and decompression The pipeline is connected in parallel with the high-pressure bypass water spraying desuperheating and decompression pipeline, and the high-flow high-pressure bypass water spraying desuperheating and decompression pipeline includes a large-flow water spraying desuperheating and pressure reducing device 22. The inlet of the temperature and pressure reducer 22 is connected with a high pressure inlet stop valve 8 and a pressure reducing valve 7 . The high-pressure inlet shut-off valve 8 is connected to a boiler, and the outlet of the large-flow water spray desuperheater 22 is connected to a reheater 21 .

[0070...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com