Ceiling lamp

A ceiling fan lamp and fan technology, applied in the field of ceiling fan lamps, can solve the problems of insufficient blade smoothness, large tooth resistance, cumbersome installation, etc., and achieve the effects of smooth display and storage, smooth and stable improvement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

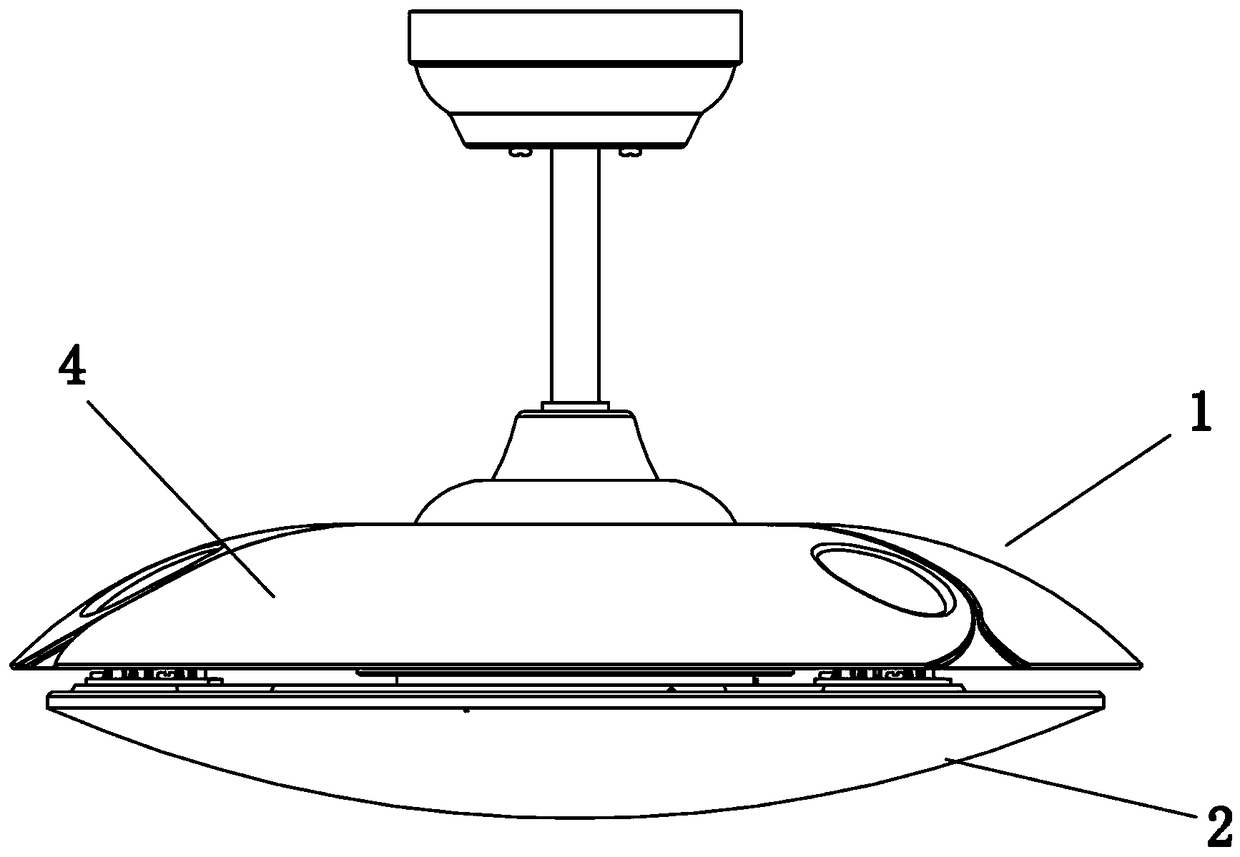

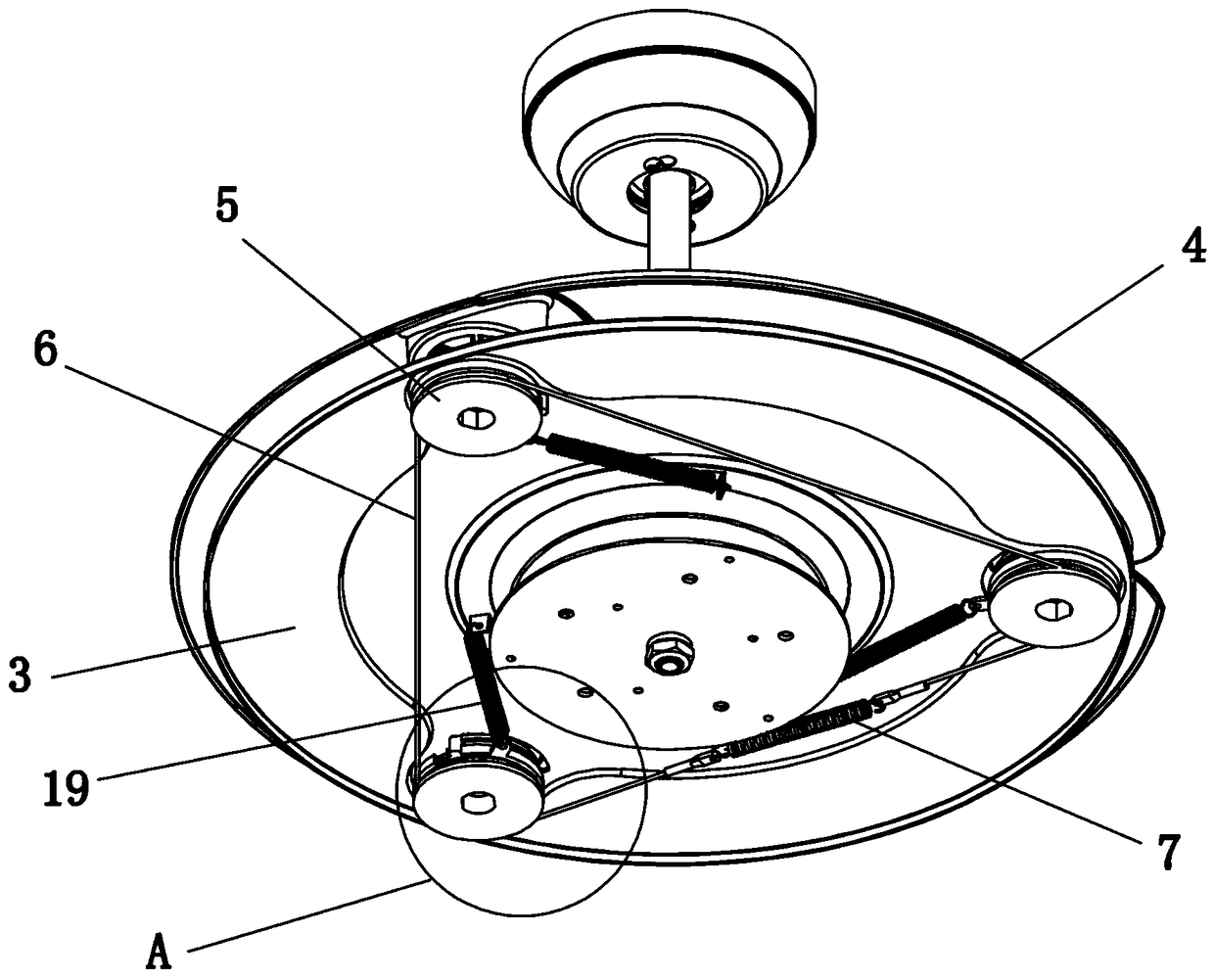

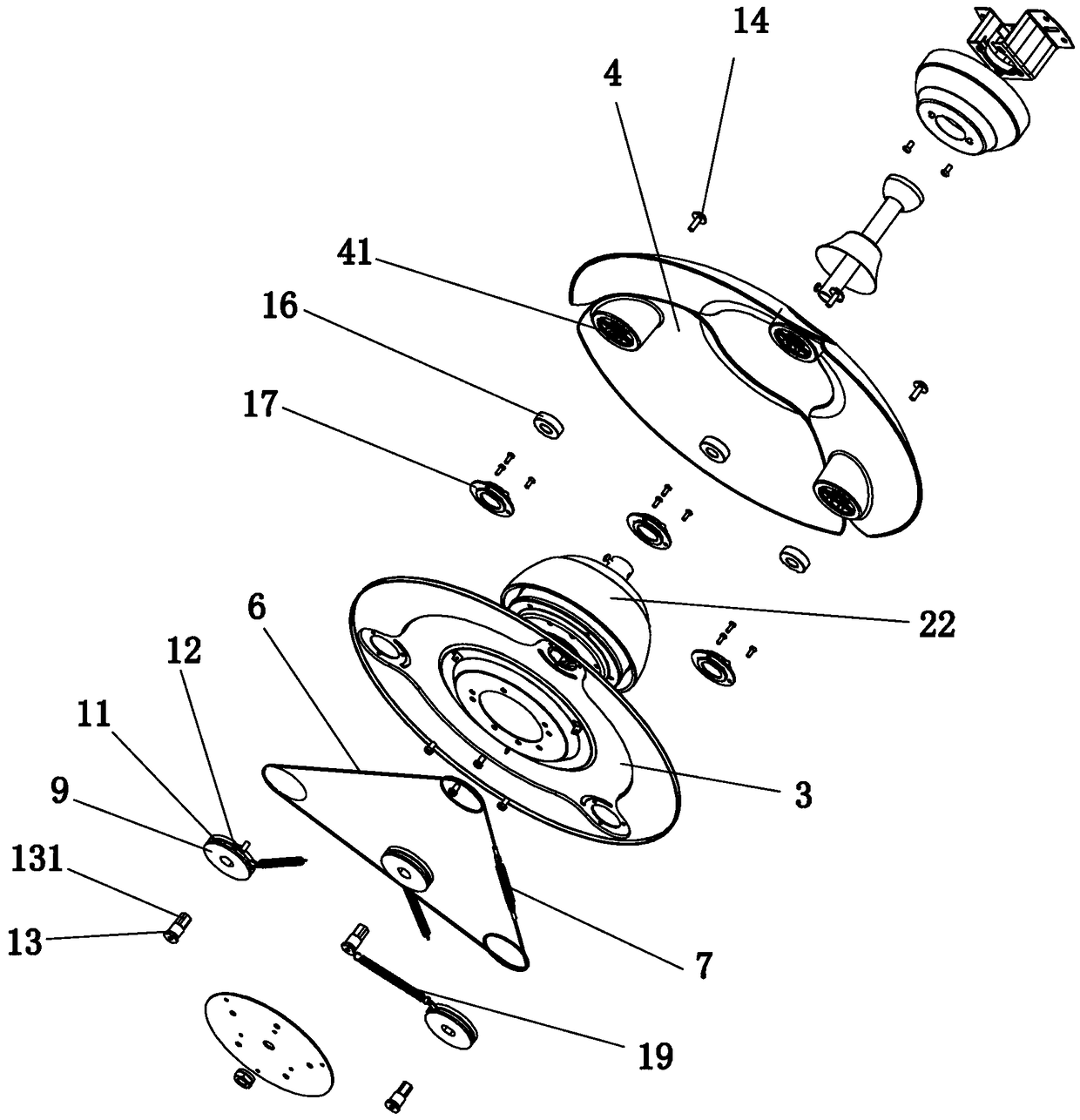

[0041] Embodiment one: if Figure 1 to Figure 10 As shown, a ceiling fan lamp includes a fan part 1 and a lamp part 2. The fan part 1 includes a rotating disk 3, at least two fan blades 4 and at least two sets of rotating wheel assemblies 5, and each fan blade 4 passes through Each group of rotating wheel assemblies 5 is installed on the rotating disk 3, and is characterized in that it also includes a synchronous rope 6, and the synchronizing rope 6 is wound on each group of synchronizing wheel assemblies 5, so that each fan blade 4 is positioned on the rotating disk. 3, synchronously slide out and synchronously retract for storage, and the synchronous rope 6 is also provided with an elastic member 7, and the elastic member 7 is connected to both ends of the synchronous rope 6. In this embodiment, the elastic member 7 is Extension spring, the two ends of the extension spring are respectively connected to the two ends of the synchronous rope 6.

[0042] As a more specific soluti...

Embodiment 2

[0049] Embodiment two: if Figure 11 As shown, this embodiment is similar to the first embodiment above, the only difference is that the elastic member 7 is replaced by a tensioning wheel 8, the tensioning wheel 8 is arranged on the rotating disk 3, and the synchronous rope 6 is wound around On the tensioning pulley 8, the tensioning pulley 8 also plays the role of tightening the synchronous rope to prevent the synchronous rotation between the groups of running wheel assemblies 5 from being loosened due to the synchronous rope 6.

[0050] Working principle: when working, the motor 22 drives the rotating disk 3 to rotate, and the fan blade 4 slides and unfolds under the action of centrifugal force, and drives the rotating wheels 9 to rotate. 18, so that the rotating wheel 9 can rotate within a certain range, so that each fan blade 4 can be slid and displayed synchronously on the rotating disk 3 .

[0051] When the motor 22 is powered off, the rotating disk 3 stops rotating, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com