Image sensor and formation method thereof

A technology of image sensor and interlayer dielectric layer, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc. It can solve the problems that the size of the metal grid is not easy to control, etc., so as to ensure performance, save costs and reduce usage. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

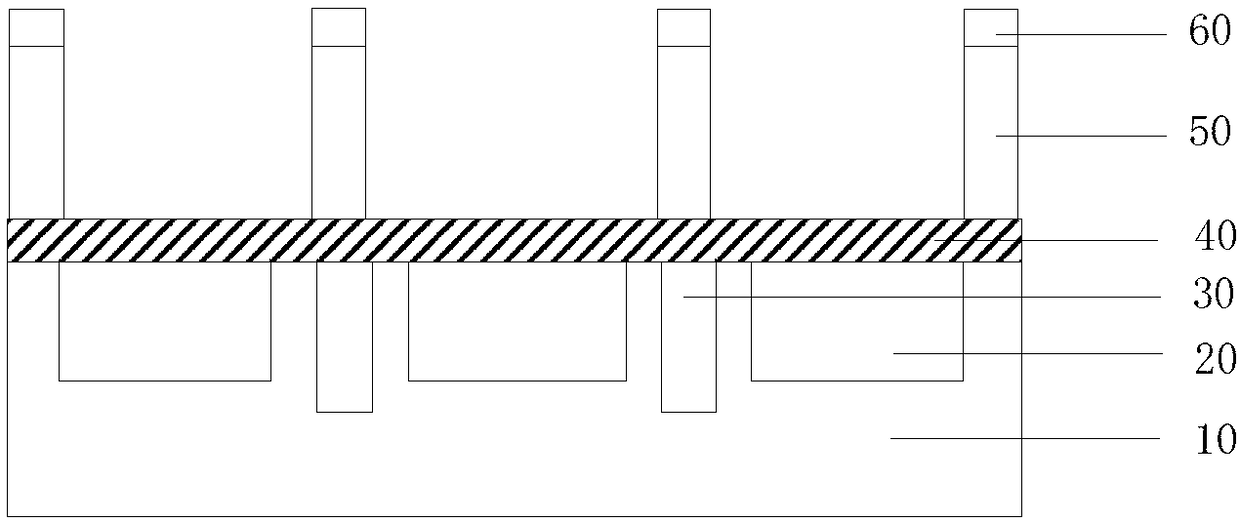

[0030] Figure 2 to Figure 9 It is a structural diagram corresponding to each step of the method for forming the back-illuminated image sensor in the first embodiment of the present invention.

[0031] refer to figure 2 , providing a semiconductor substrate 110, forming a discrete photodiode 120 in the semiconductor substrate 110; forming a deep trench isolation structure 130 in the semiconductor substrate 110, and the deep trench isolation structure 130 is located at the photodiode 120 between, and the depth of the deep trench isolation structure 130 is deeper than that of the photodiode 120, so as to obtain a better isolation effect and avoid the problem of photo-generated carrier diffusion between different pixel regions; in the semiconductor An interlayer dielectric layer 140 is formed on the surface of the substrate 110 , and the interlayer dielectric layer 140 covers the photodiode 120 and the deep trench isolation structure 130 .

[0032] In this embodiment, the semi...

no. 2 example

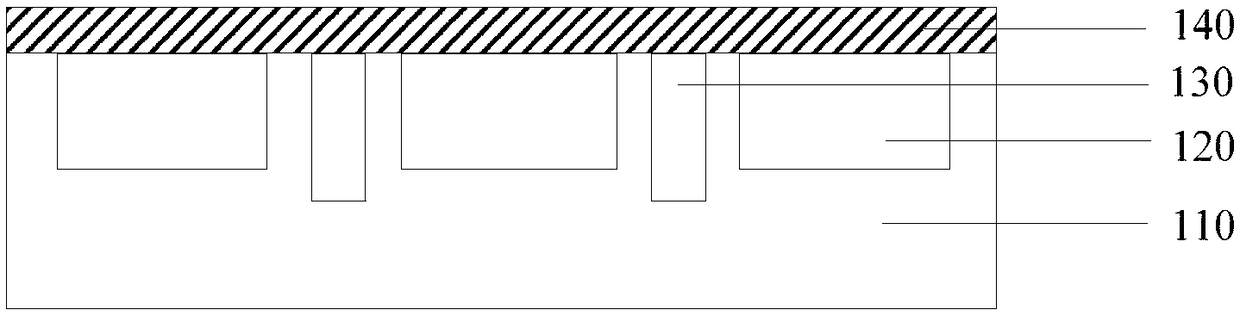

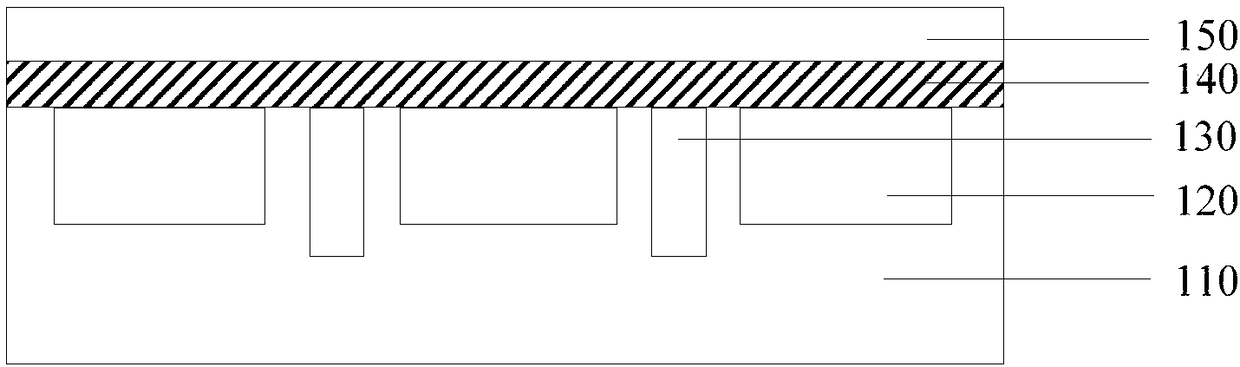

[0058] Figure 10 to Figure 18 It is a structural diagram corresponding to each step of the method for forming a back-illuminated image sensor in the second embodiment of the present invention.

[0059] refer to Figure 10 , providing a semiconductor substrate 210, forming a discrete photodiode 220 in the semiconductor substrate 210; forming a deep trench isolation structure 230 in the semiconductor substrate 210, and the deep trench isolation structure 230 is located at the photodiode 220 between, and the depth of the deep trench isolation structure 230 is deeper than that of the photodiode 220, so as to obtain a better isolation effect and avoid the problem of photo-generated carrier diffusion between different pixel regions; in the semiconductor An interlayer dielectric layer 240 is formed on the surface of the substrate 210 , and the interlayer dielectric layer 240 covers the photodiode 220 and the deep trench isolation structure 230 .

[0060] In this embodiment, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com