Electrolyzed water generation device and production device for water for dialysate preparation and method for electrolyzed water generation that use same

A technology for generating device and electrolyzing water, applied in electrochemical water/sewage treatment, dialysis system, etc., which can solve the problems of oxygen retention, difficulty in increasing dissolved hydrogen concentration, and oxygen discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

[0034] (first invention)

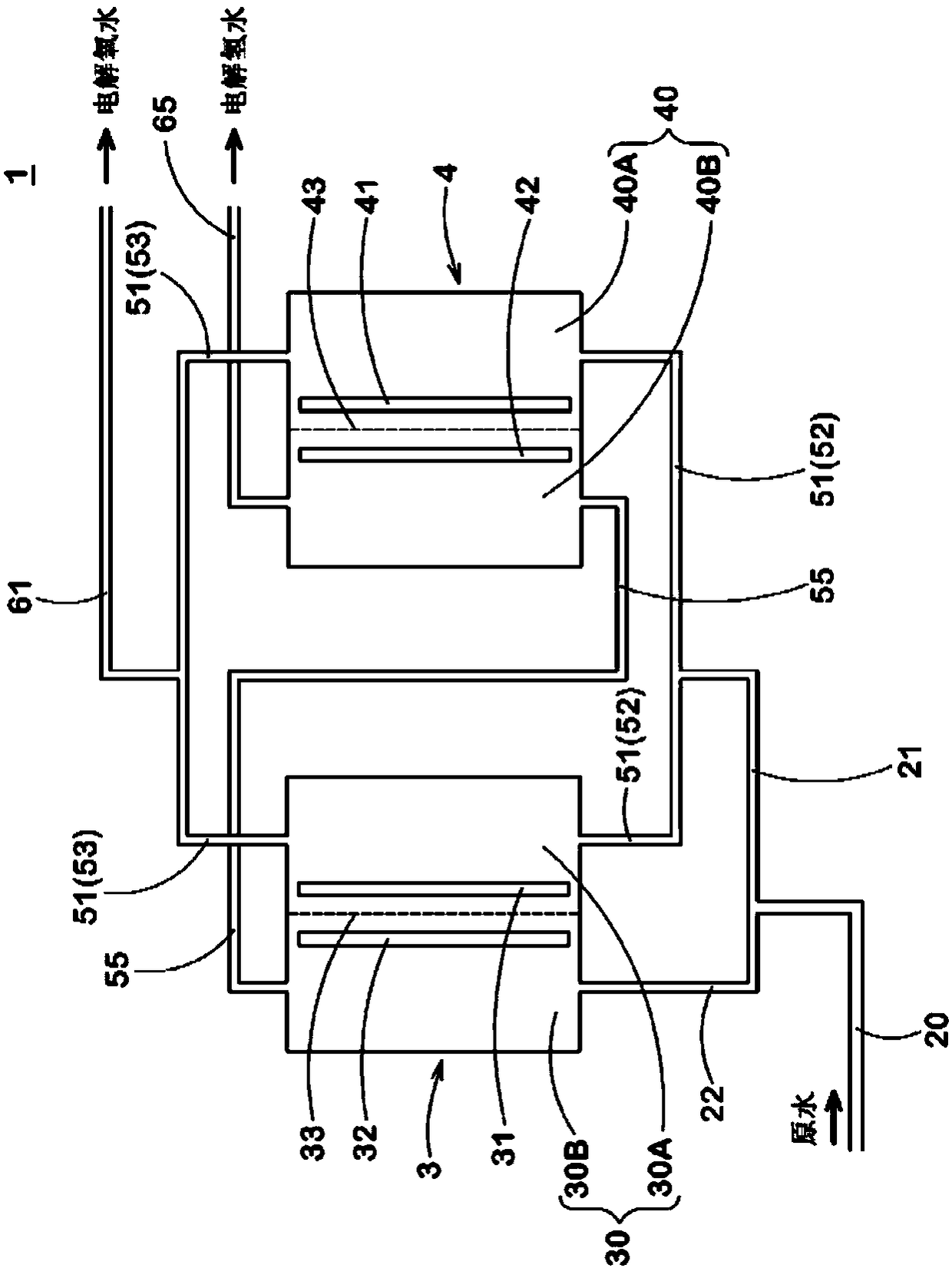

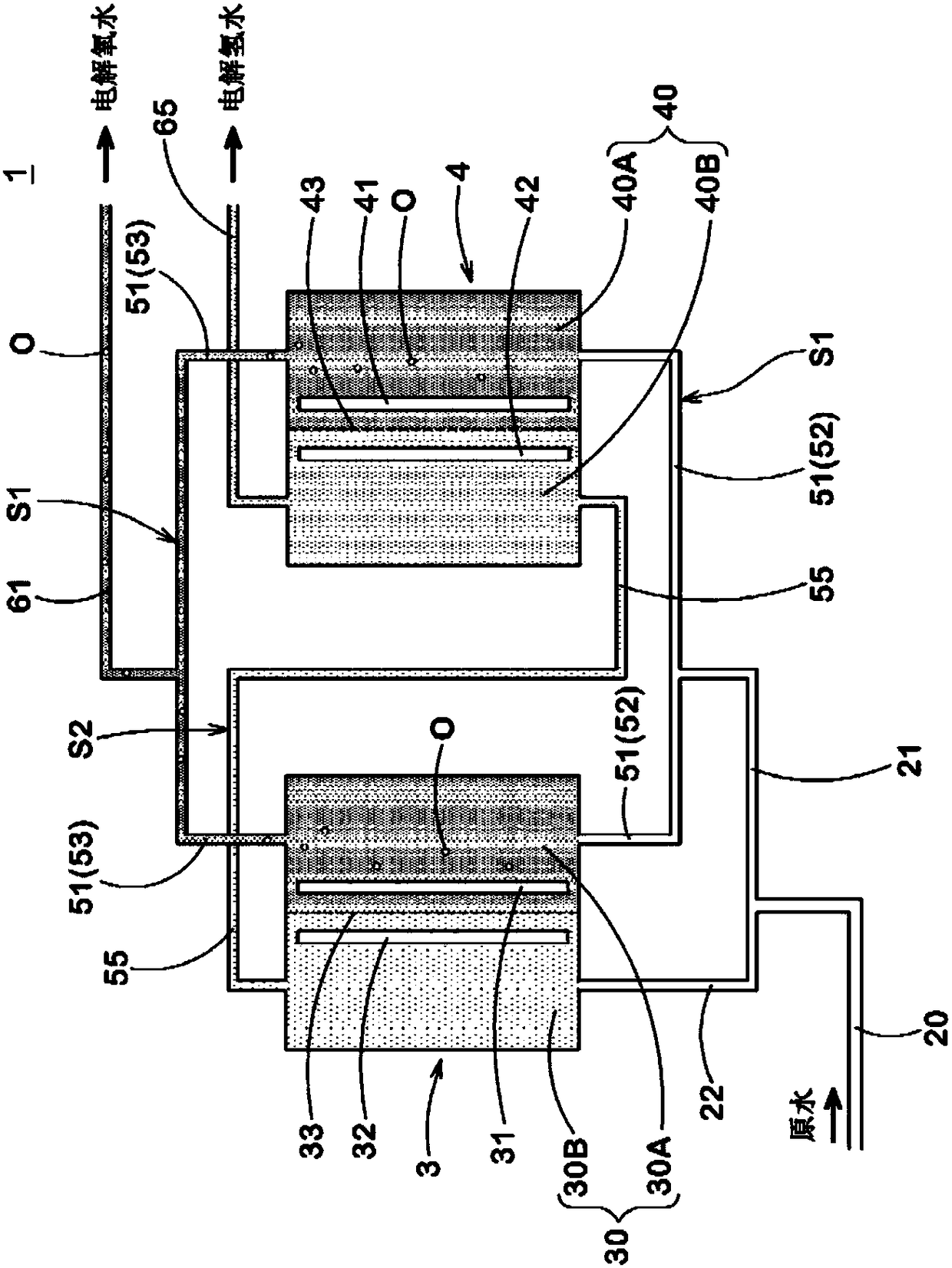

[0035] figure 1 The schematic structure of the flow path of the electrolyzed water generator 1 which is embodiment of the 1st invention is shown. The electrolyzed water generator 1 is widely used in the production of domestic drinking water, in addition to the production of dialysate preparation water, for example.

[0036] The electrolyzed water generator 1 includes a plurality of electrolytic cells 3, 4, . . . . figure 1 In , the electrolyzed water generator 1 provided with a pair of electrolytic cells 3 and 4 is shown. The electrolyzed water generator 1 may include three or more electrolytic cells 3, 4, . . . .

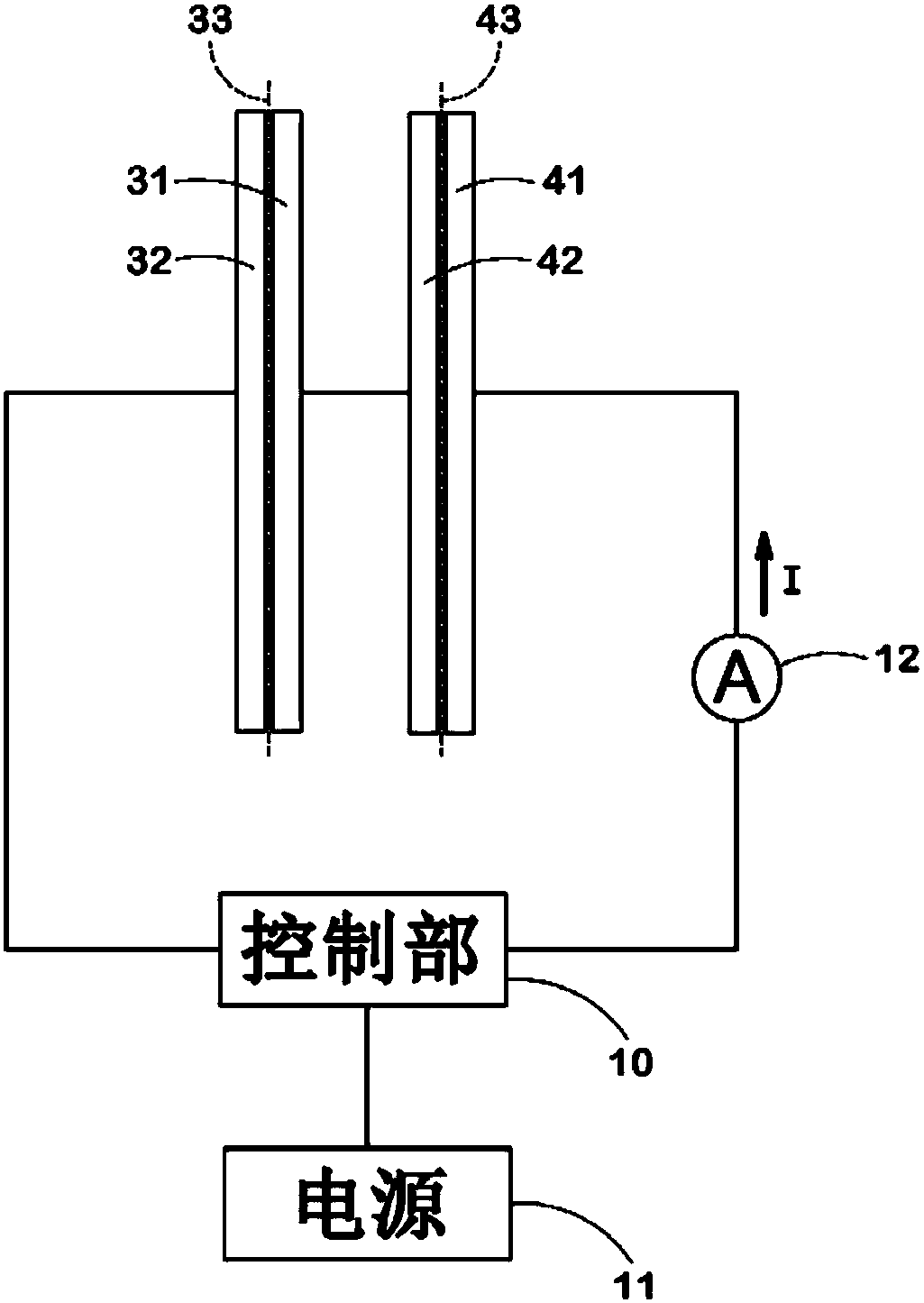

[0037] The electrolytic cell 3 has: an electrolysis chamber 30 for electrolyzing water; a first power supply body 31 and a second power supply body 32 disposed opposite to each other in the electrolysis chamber 30; The diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com