Cooling apparatus used for production process of dairy products

A production process and cooling device technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as loss of enterprises, affecting the quality of yogurt, and difficulty in cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

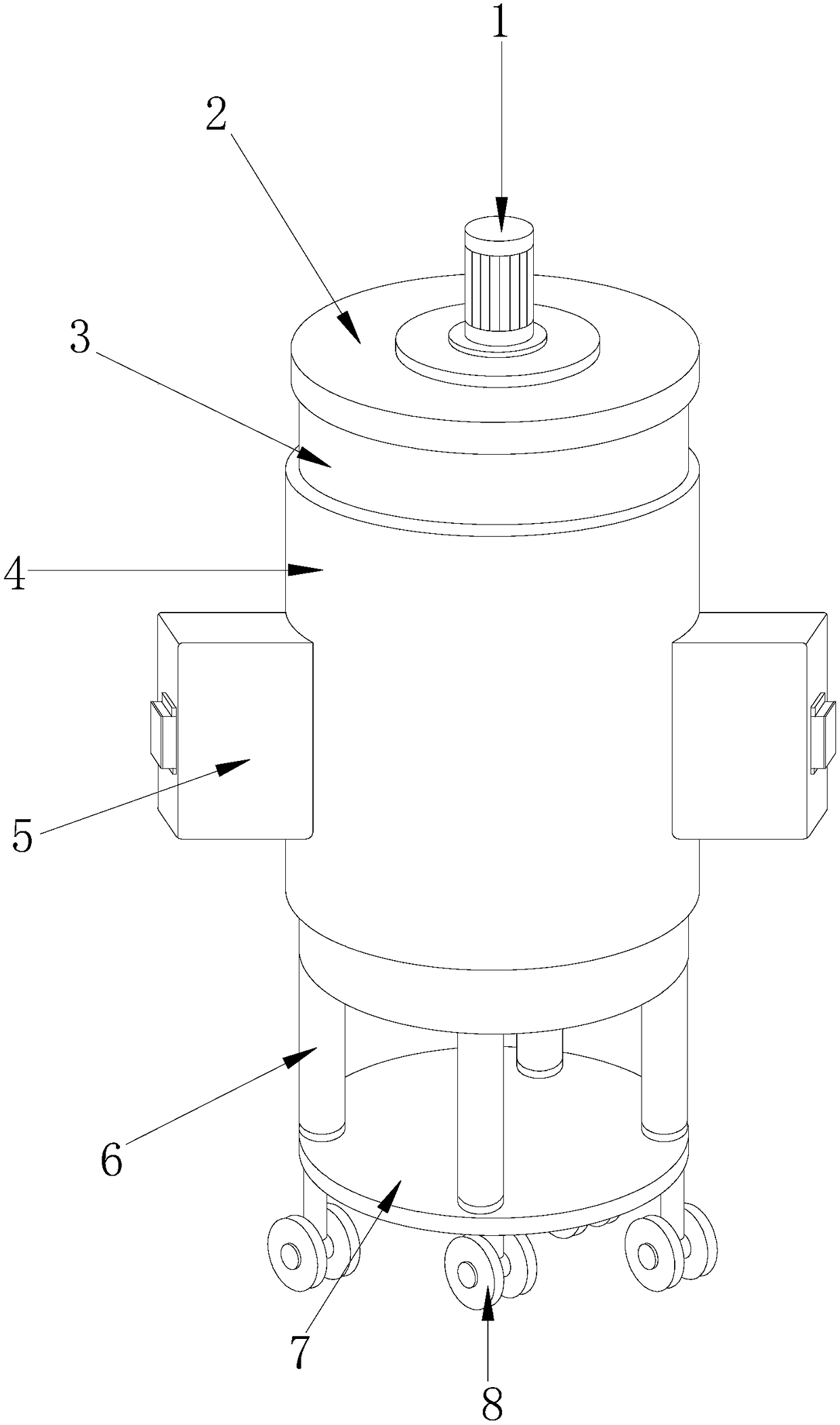

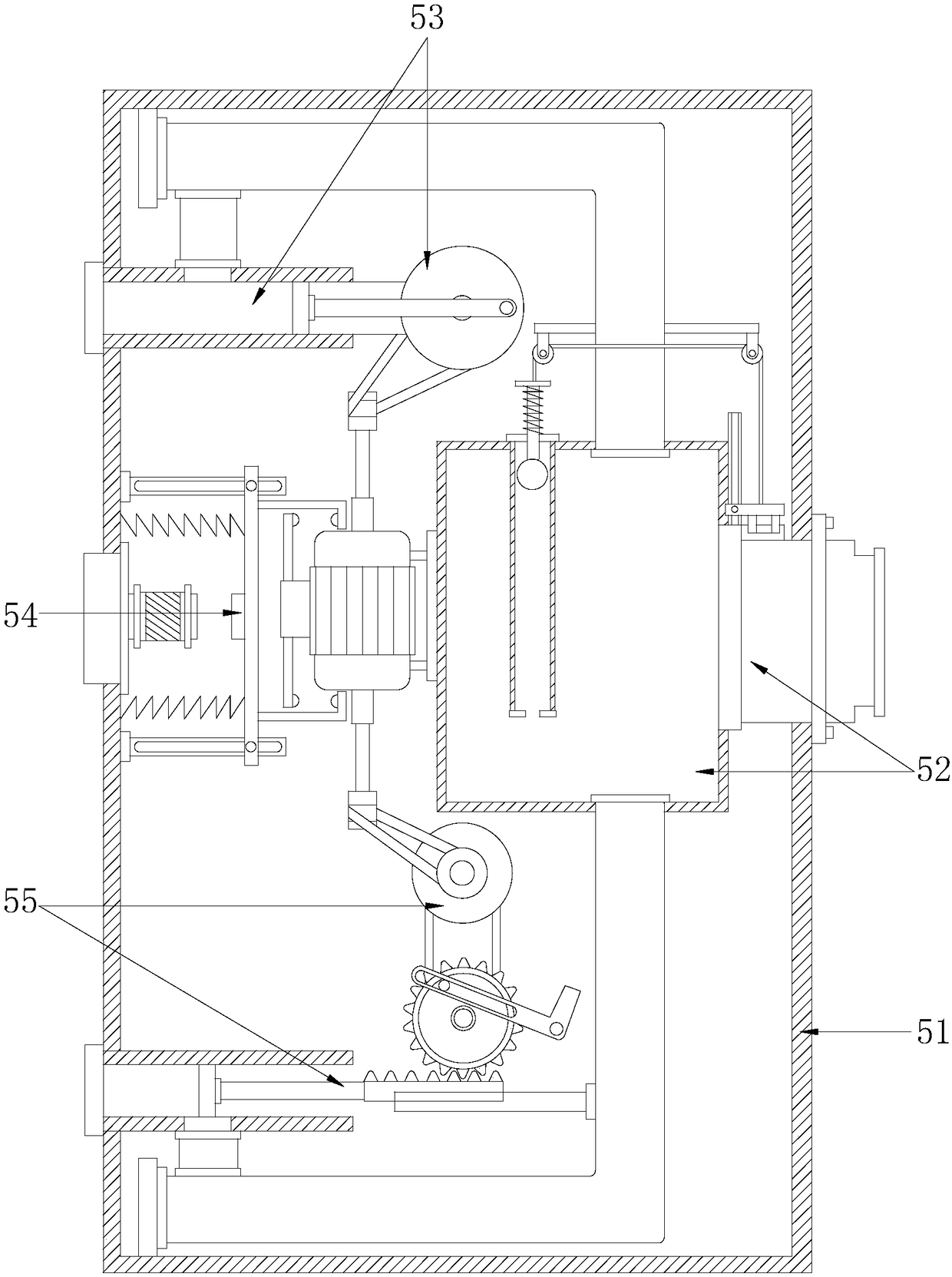

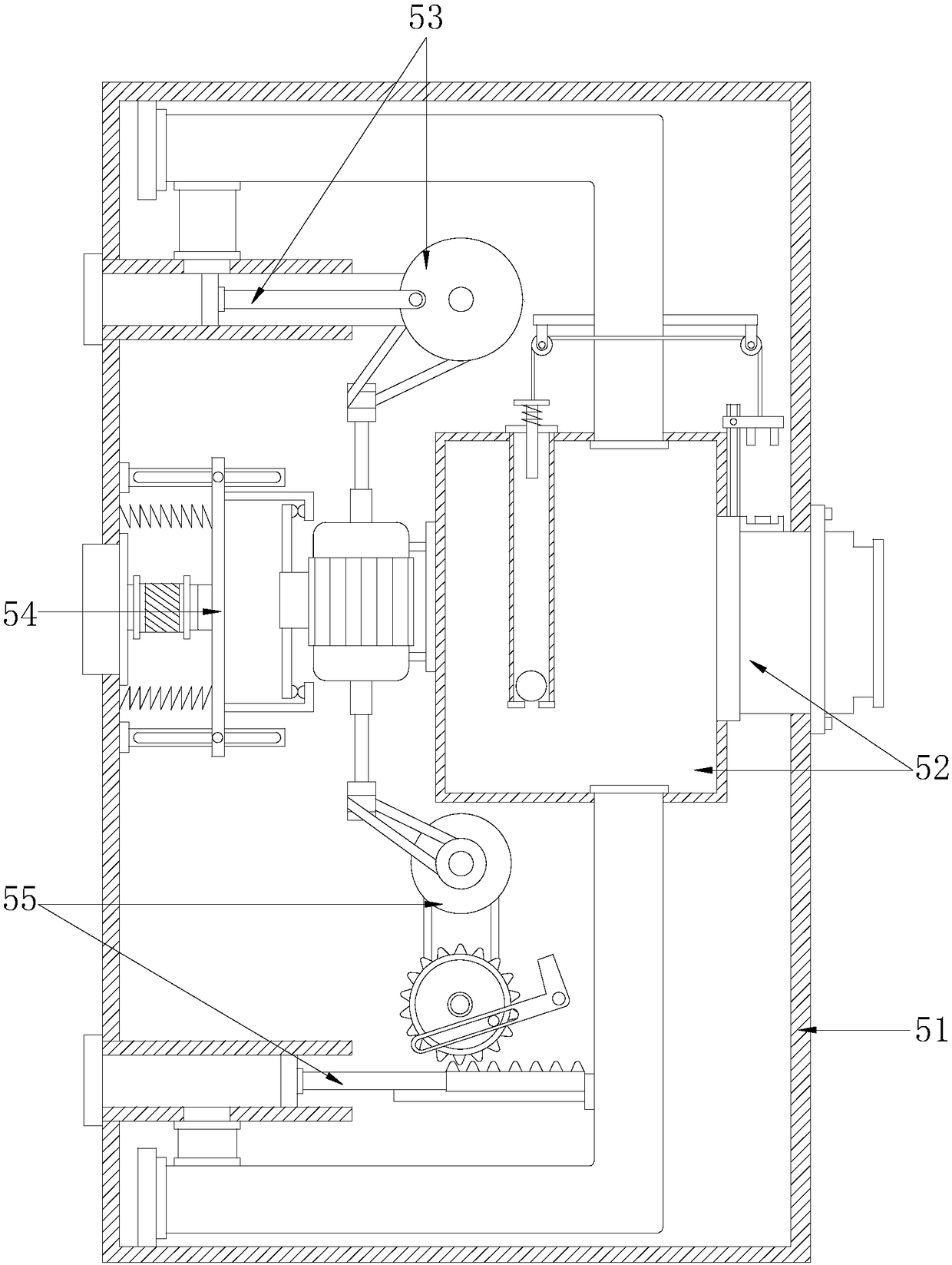

[0027] see Figure 1-Figure 5 , the present invention provides a cooling device for the production process of dairy products, the structure of which includes a stirring motor 1, a top cover 2, a stirring box for dairy products 3, a refrigeration liquid circulation backflow cooling cover 4, a rapid cooling device for dairy products 5, a pillar 6, a circular Plate base 7, universal caster 8, described dairy product stirring box 3 is cylindrical and top is provided with top cover 2, and described top cover 2 and dairy product stirring box 3 are screwed together, and described top cover 2 A stirring motor 1 is provided at the center of the top, and the two adopt an interference fit. The stirring motor 1 is matched with the dairy product stirring box 3, and the bottom of the dairy product stirring box 3 is provided with four pillars 6 evenly and equidistantly. The upper end of the pillar 6 is welded to the bottom surface of the dairy product stirring box 3, the dairy product stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com