High-efficient sugar-permeating technology of fruit flesh

A pulp and sugar infiltration technology is applied in confectionery, confectionary industry, food science, etc. It can solve the problems of skin color browning, tissue cell structure damage, and nutritional value decline, so as to reduce the loss of nutrients and maintain Effects of shape and flavor and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

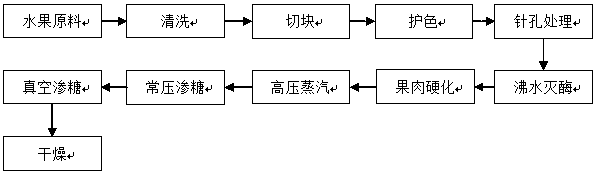

Image

Examples

Embodiment 1

[0026] (1) After washing and cutting the fruit raw materials, soak the pulp in an aqueous color-protecting agent mixed with 0.6% citric acid, 0.4% ascorbic acid, and 0.4% zinc chloride for 4 minutes; reuse The pinhole device is inserted into the pulp, so that the pinholes are evenly distributed; the pulp treated with pinholes is soaked in boiling water for 5-10 seconds; finally, the pulp that has been deactivated by boiling water is soaked in 0.3% calcium chloride solution, Carry out pulp hardening treatment, hardening time 5min;

[0027] (2) Put the product obtained in step (1) into a high-pressure steam tank for steam pressurization treatment for 10 minutes at a temperature of 100°C and a pressure of 0.115Mpa;

[0028] (3) Put the product obtained in step (2) into a cooking pot, and carry out normal pressure osmosis, osmosis time 40min, temperature 70°C, and sugar solution concentration 35%;

[0029] (4) Put the product obtained in step (3) into a vacuum osmosis tank, and c...

Embodiment 2

[0033] (1) After washing and cutting the fruit raw materials, soak the pulp in an aqueous color-protecting agent mixed with 0.6% citric acid, 0.4% ascorbic acid, and 0.4% zinc chloride for 4 minutes; reuse The pinhole device is inserted into the pulp, so that the pinholes are evenly distributed; the pulp treated with pinholes is soaked in boiling water for 5-10 seconds; finally, the pulp that has been deactivated by boiling water is soaked in 0.3% calcium chloride solution, Carry out pulp hardening treatment, hardening time 5min;

[0034] (2) Put the product obtained in step (1) into a high-pressure steam tank for steam pressurization treatment, pressurization time is 8min, temperature is 105°C, and pressure is 0.12Mpa;

[0035] (3) Put the product obtained in step (2) into a cooking pot, and carry out normal pressure osmosis, osmosis time is 30 minutes, temperature is 65°C, and the concentration of sugar solution is 32%;

[0036] (4) Put the product obtained in step (3) into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com