Suspended pickling exhaust filtration recovery device

A waste gas filtration and recovery device technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of endangering human health, hydrogen in explosion accidents, and no recycling, etc., to achieve high working efficiency and long service life , the effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

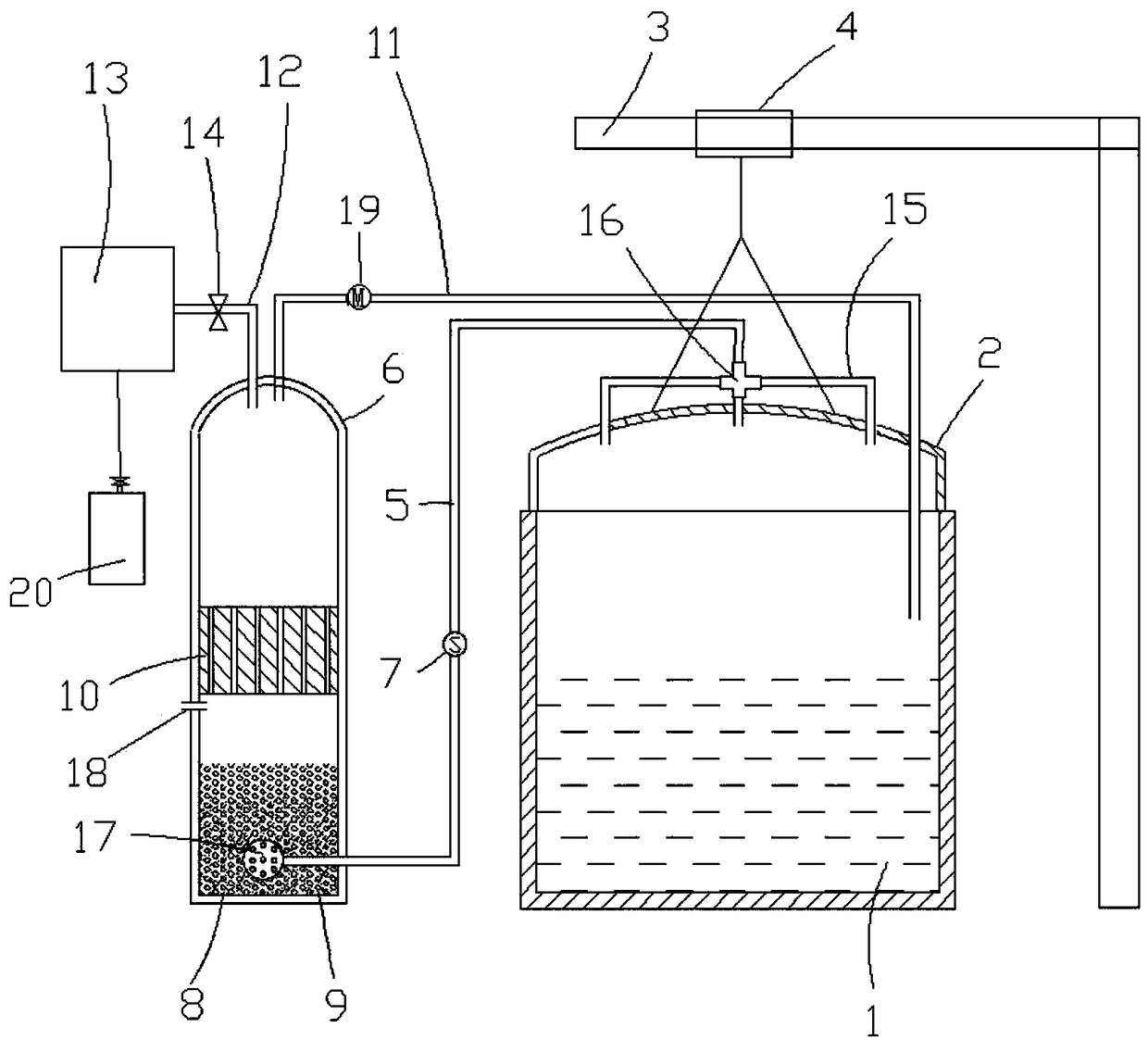

[0018] Example. Suspension pickling exhaust gas filtration recovery device, such as figure 1 As shown, it includes a gas collection hood 2 arranged above the pickling tank 1 and a cantilever crane 3 arranged on one side of the pickling tank 1. The cantilever crane 3 is provided with an electric hoist 4 connected to the gas collection hood 2, and the gas collection hood 2 Connect with the filter tower 6 through the first pipeline 5, one end of the first pipeline 5 is set on the lower floor of the filter tower 6, the first pipeline 5 is provided with an induced draft fan 7, and the lower floor of the filter tower 6 is provided with lye 8 and pebble piles 9. The middle layer of the filter tower 6 is provided with a quick lime layer 10, and the side wall of the middle layer of the filter tower 6 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com