Ink dispersion treatment system for producing printing ink

A technology for dispersing and printing ink, applied in chemical/physical process, mixer with rotary stirring device, dissolving and other directions, can solve the problems affecting the quality of ink production, the effect of dispersion needs to be improved, and the position change cannot be carried out. Achieve the effect of improving production efficiency, reducing manual operation steps, and reducing the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

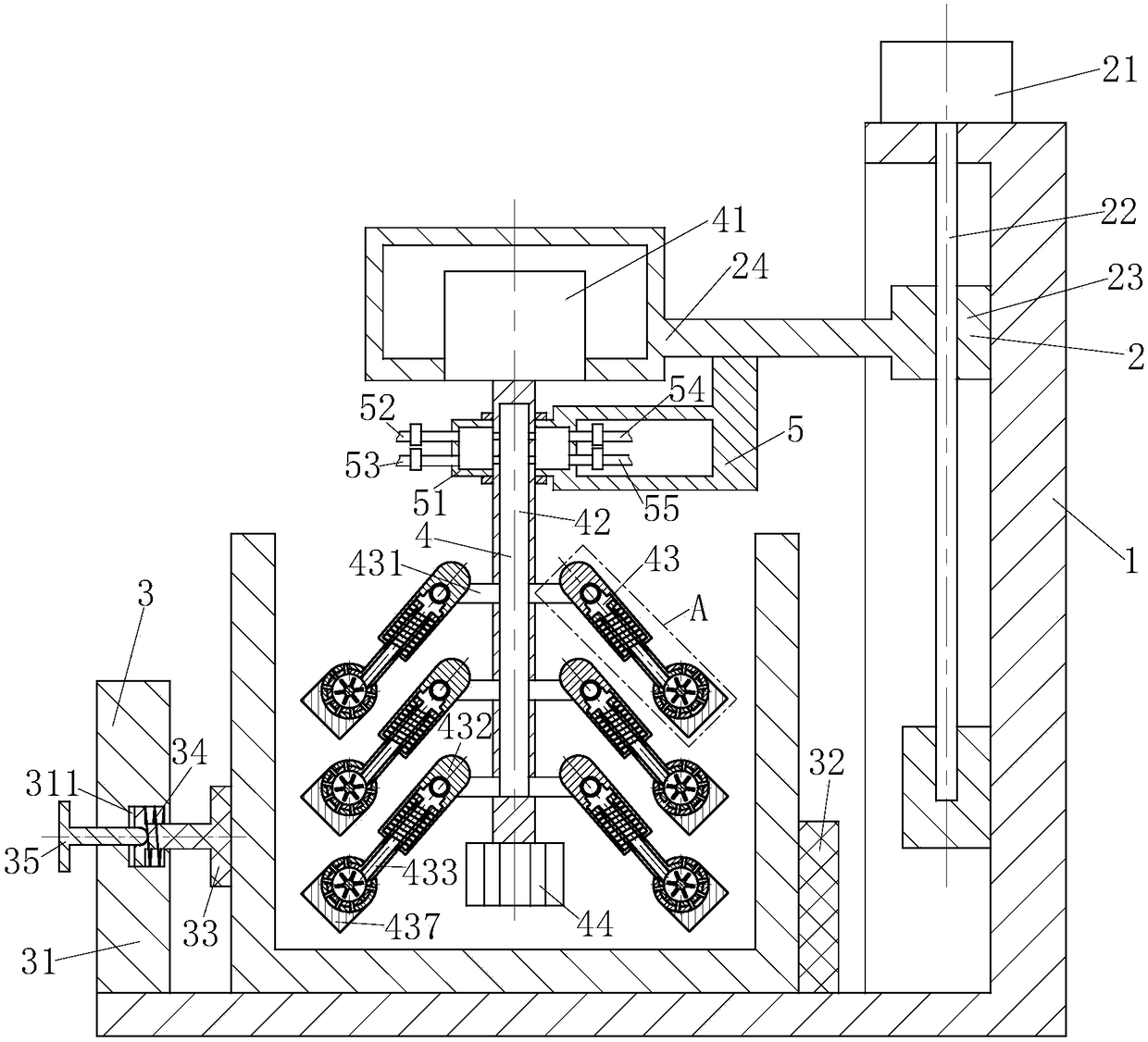

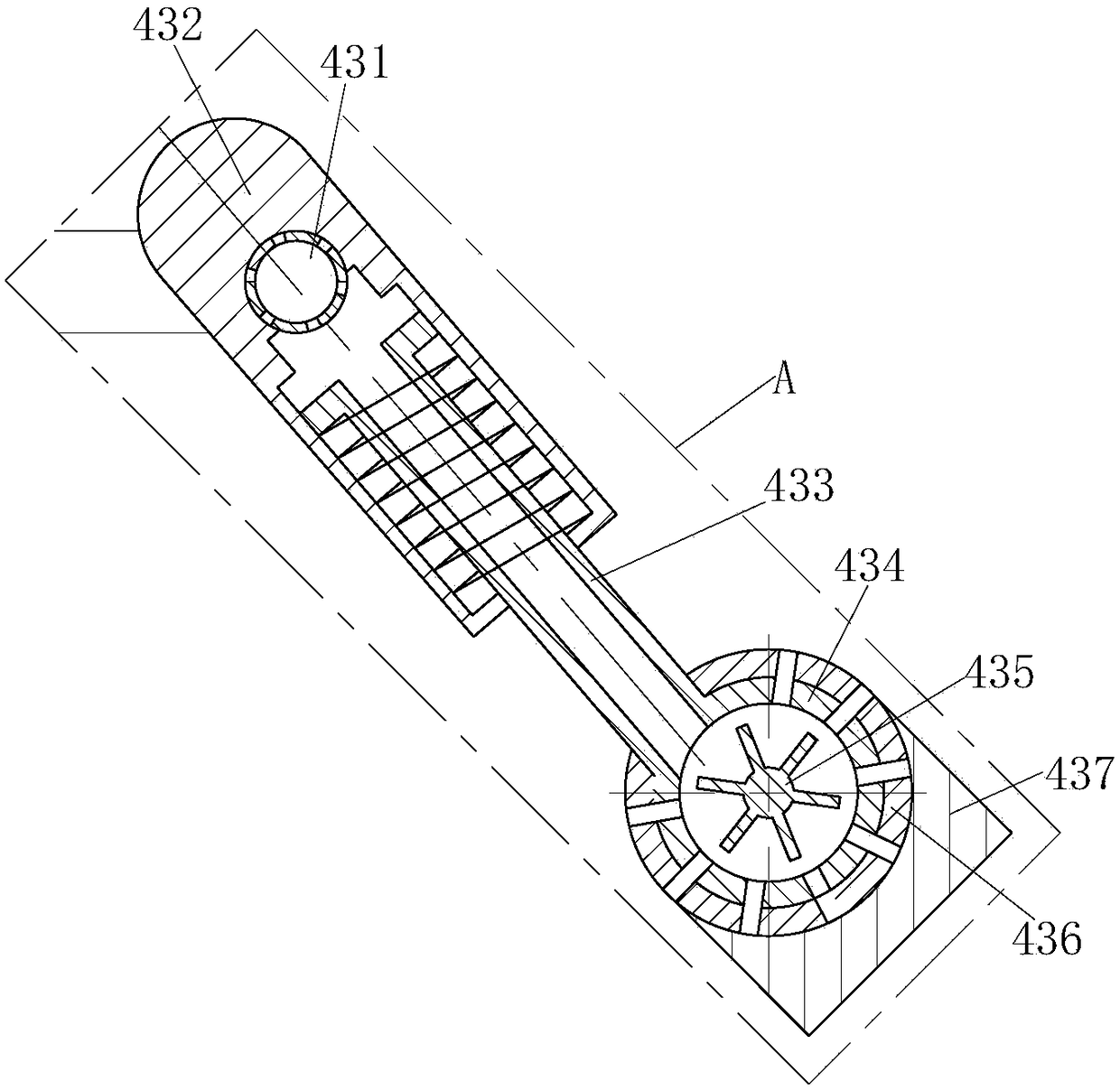

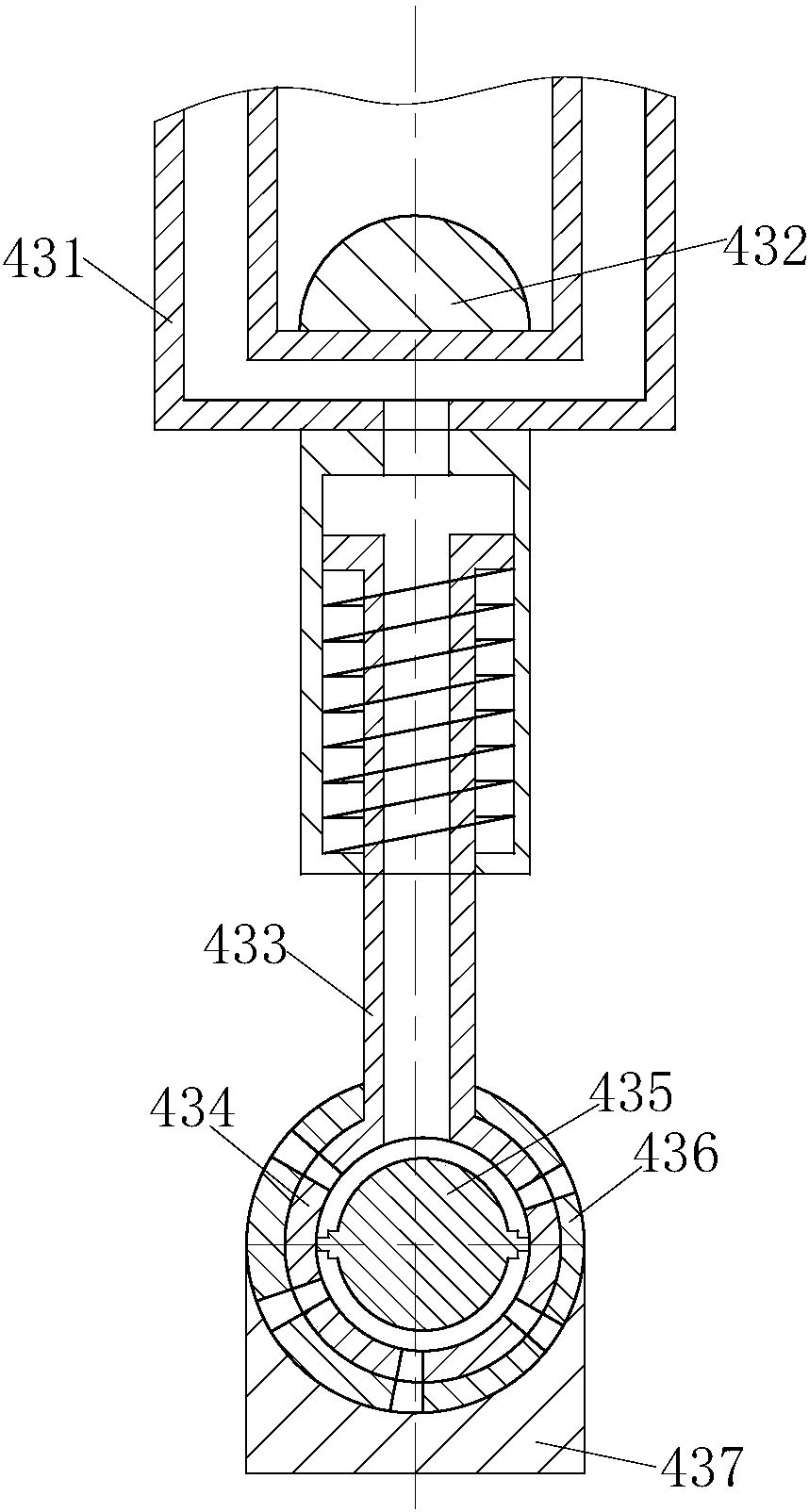

[0024] Such as Figure 1 to Figure 4 As shown, an ink dispersion processing system for printing ink production includes a frame 1, a lifting module 2, a clamping module 3, a main working module 4 and an introduction module 5; the lifting module 2 is located at the top of the frame 1, The lifting module 2 is slidingly connected with the frame 1, and the lifting module 2 is used to drive the main working module 4 to rise or fall; the clamping module 3 is fixedly connected to the lower part of the frame 1, and the clamping module 3 is used to clamp and fix the dispersion cylinder 6; the main working module 4 is located directly above the clamping module 3, and the main working module 4 is used to disperse the ink in the dispersion cylinder 6, add aux...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap