A modular self-balancing vibrating screen exciter and excitation system

A vibrating screen, self-balancing technology, applied in chemical instruments and methods, filter screens, solid separation, etc., can solve the problems of difficult synchronization, heavy structure dead, limited application, etc., to reduce intermediate deflection, reduce overall size, eliminate additional The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

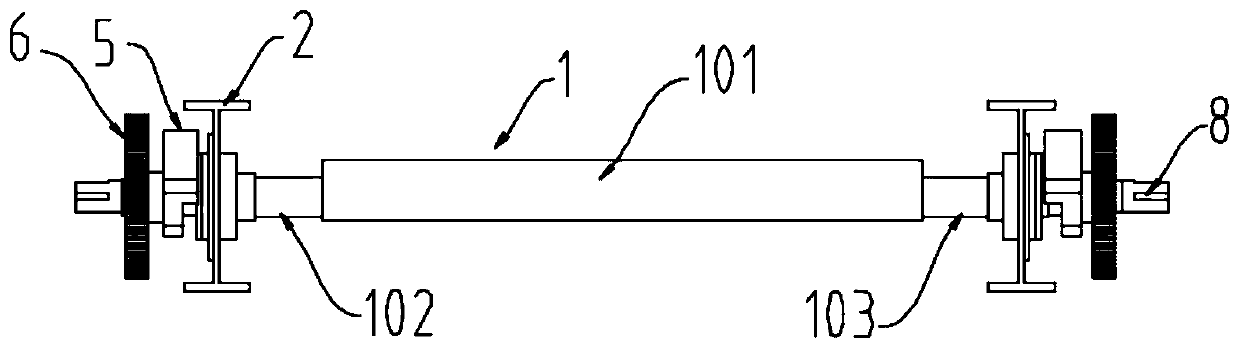

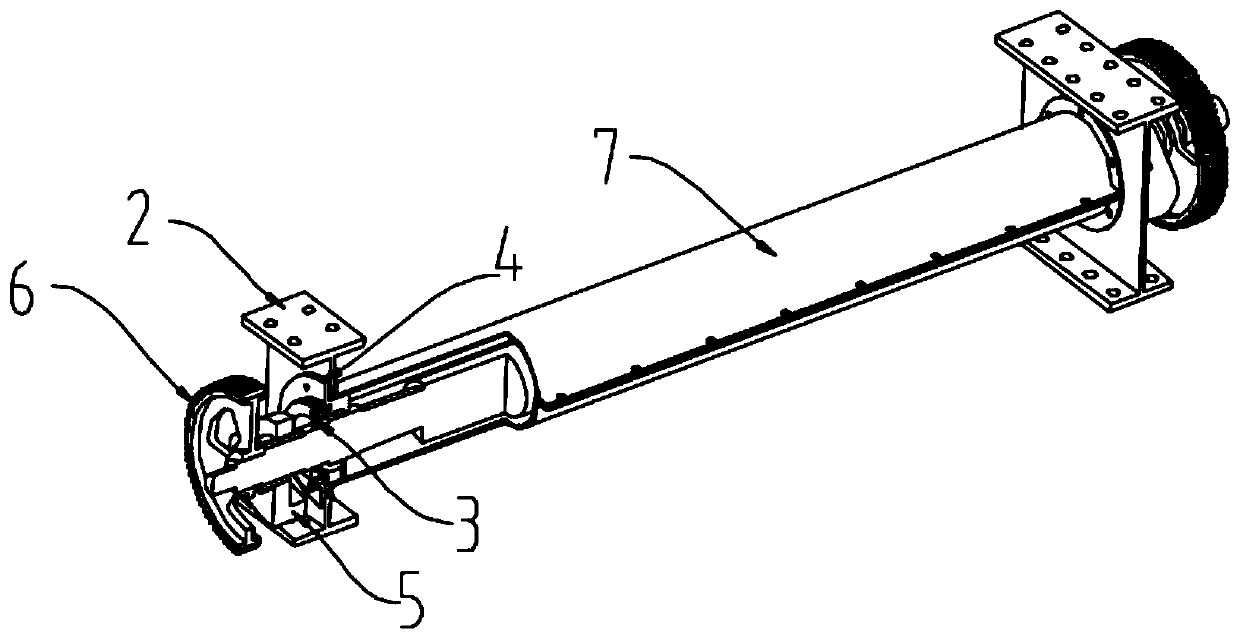

[0021] Such as figure 1 , figure 2 As shown, a modular self-balancing vibrating screen exciter includes an eccentric shaft 1, and the eccentric shaft 1 includes an eccentric shaft body 101 and a left rotation shaft 102 and a right rotation shaft 103 respectively arranged at the left and right ends of the eccentric shaft body 101. The axes of the left rotating shaft 102 and the right rotating shaft 103 are on the same straight line, and the left rotating shaft 102 and the right rotating shaft 103 are respectively installed with an exciting support 2, a counterweight 5 and a synchronous pulley 6 from the inside to the outside. The excitation support 2 is an I-shaped support with a hole in the center, a bearing chamber 4 is installed in the center hole of the excitation support 2, and a self-aligning roller bearing 3 is installed in the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com