Bottle embryo glue melting injection molding process

A technology for melting glue and preforms, which is applied to household appliances, hollow objects, other household appliances, etc., can solve the problems of high cost, inability to carry out large-scale promotion, and expensive injection molding machines, so as to expand the scope of blank supply and enhance research and development. ability, improve the effect of the injection molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

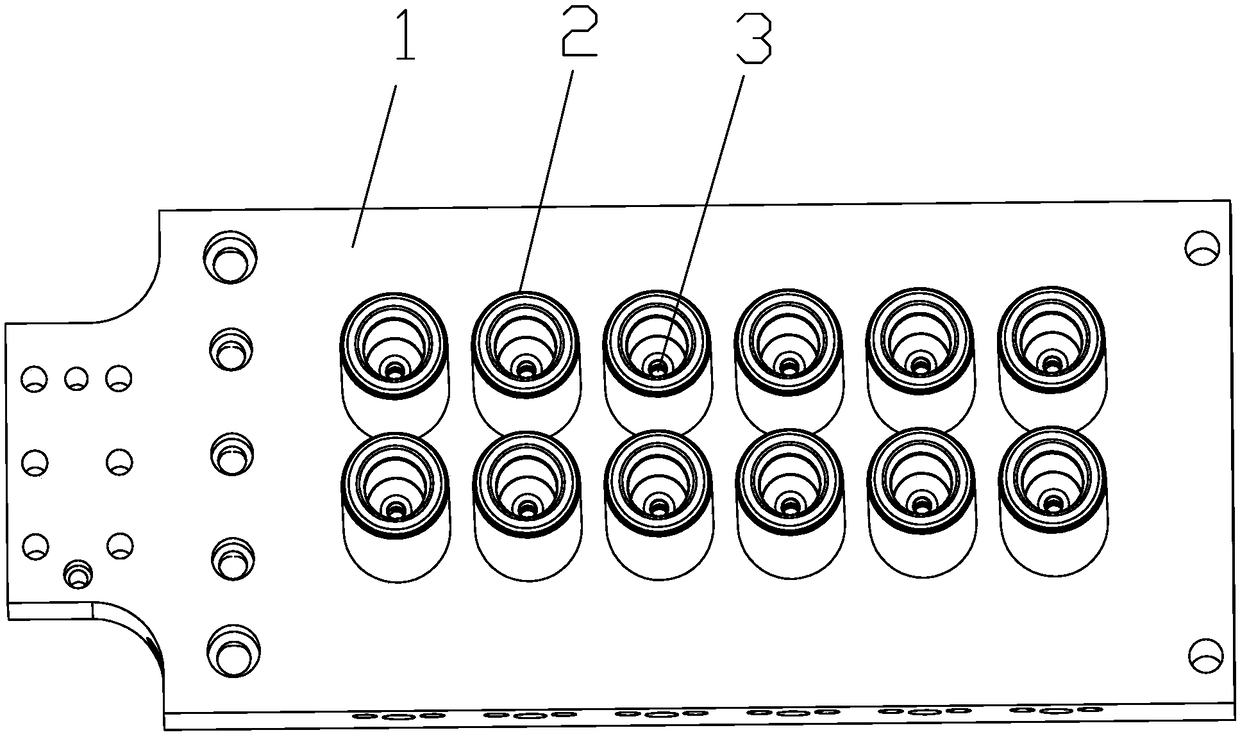

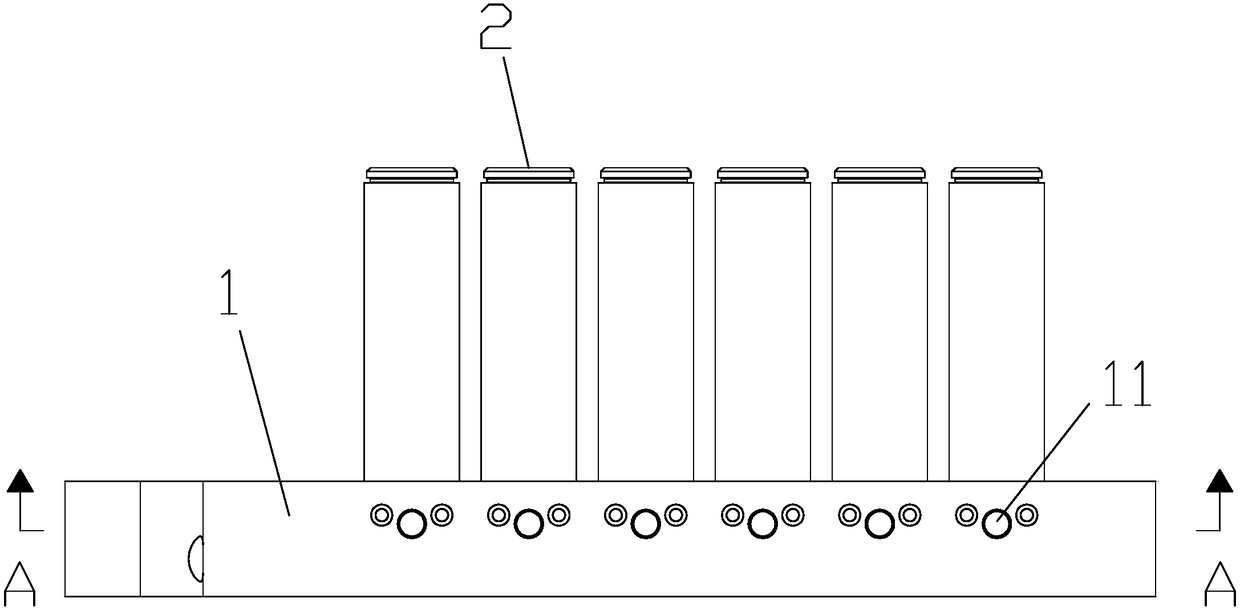

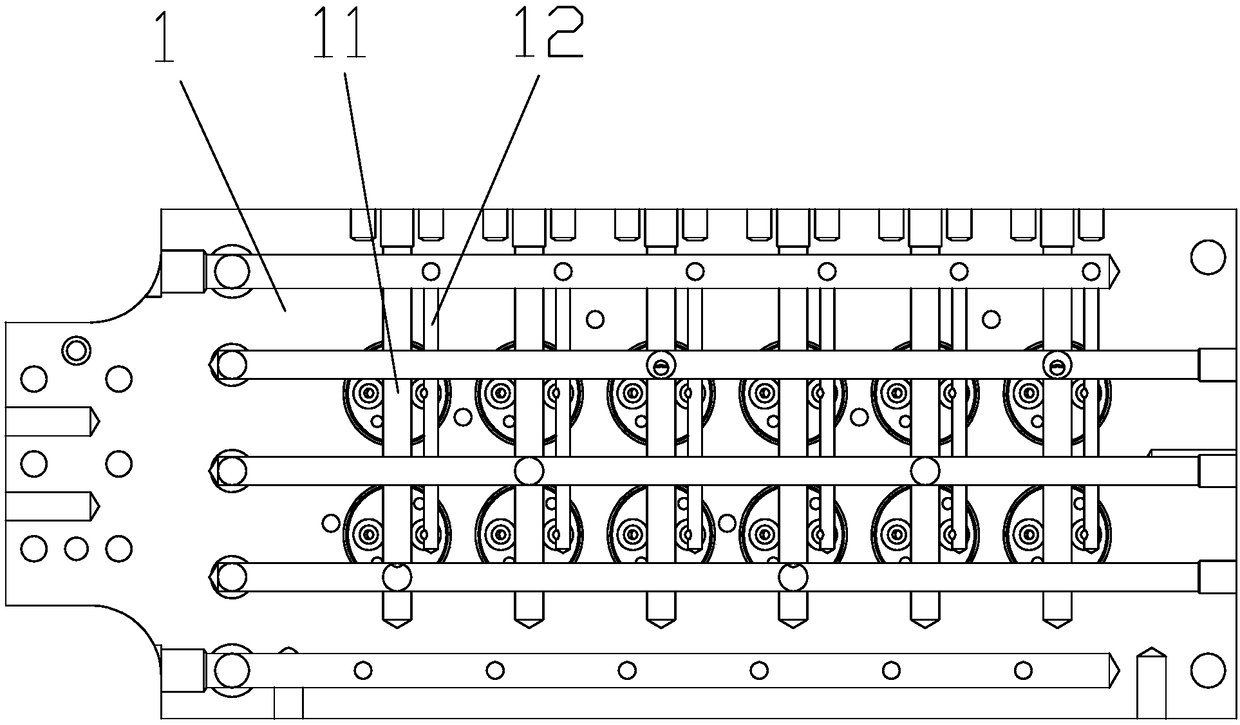

[0025] refer to Figure 1 to Figure 4 , a preform melt plastic injection molding process provided in this embodiment comprises the following steps:

[0026] Step 1, prepare the processing site and the injection molding machine, the processing site is a conventional processing workshop, a plurality of dehumidifiers are set around the processing site, so that the humidity of the processing site is below 35%, preferably 33%, and the processing site The temperature is consistent with the temperature of the cooling water of the injection molding machine, and the temperature of the cooling water is between 15°C and 33°C, preferably 19°C;

[0027] Step 2, prepare the raw material, the raw material is PET raw material, the Chinese of PET raw material is polyethylene terephthalic acid plastic, its molecular structure is highly symmetrical, has certain crystallization orientation ability, has higher film-forming property and forming property; Use a dryer to dry the PET raw material so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com