Camera motor shell shaking-off separation and typesetting device

A camera and shock-drop technology, used in image communication, stacking of objects, television, etc., can solve the problems of missing employees, high cost, waste, etc., and achieve the effect of preventing material mixing and reducing intermediate logistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

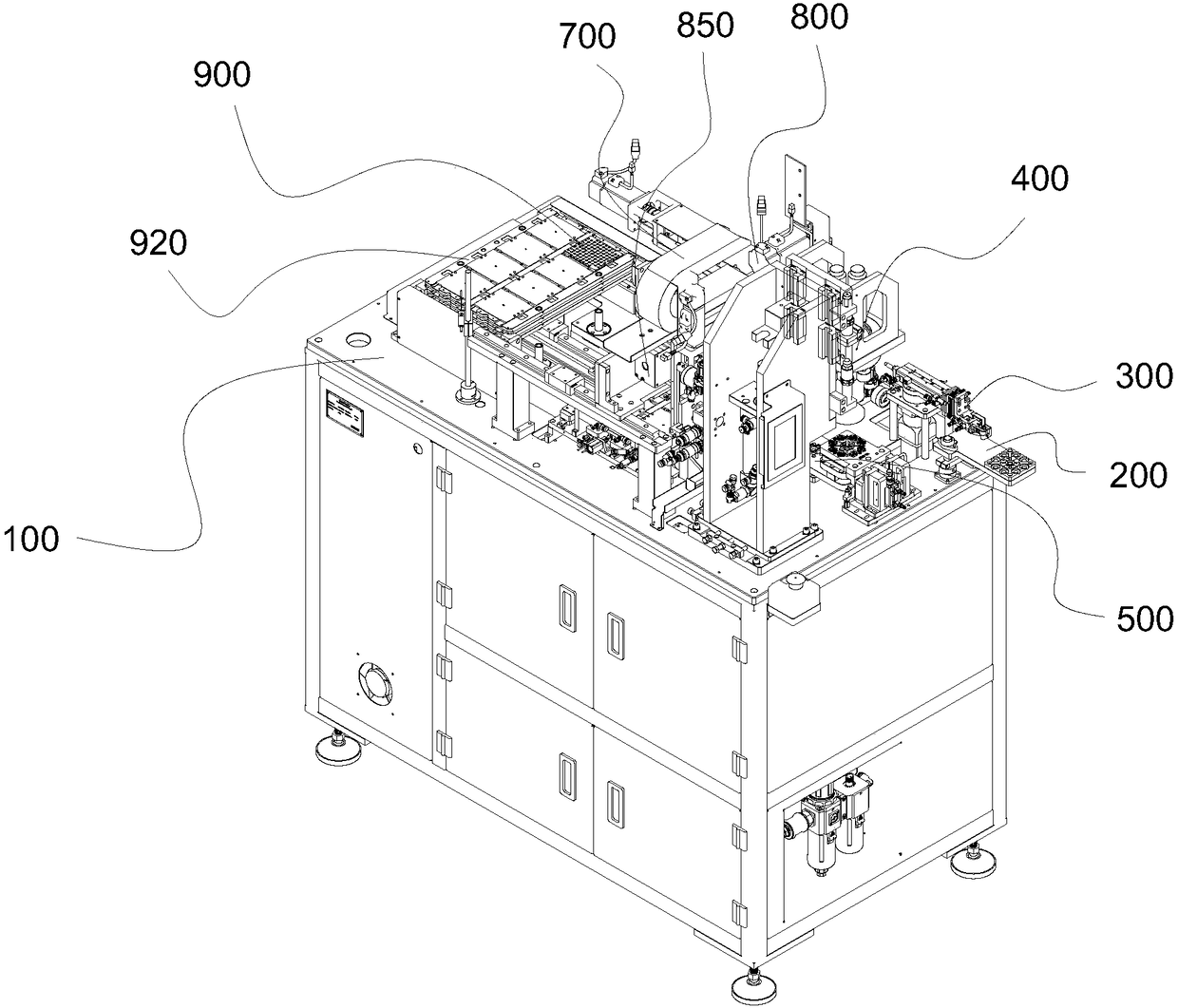

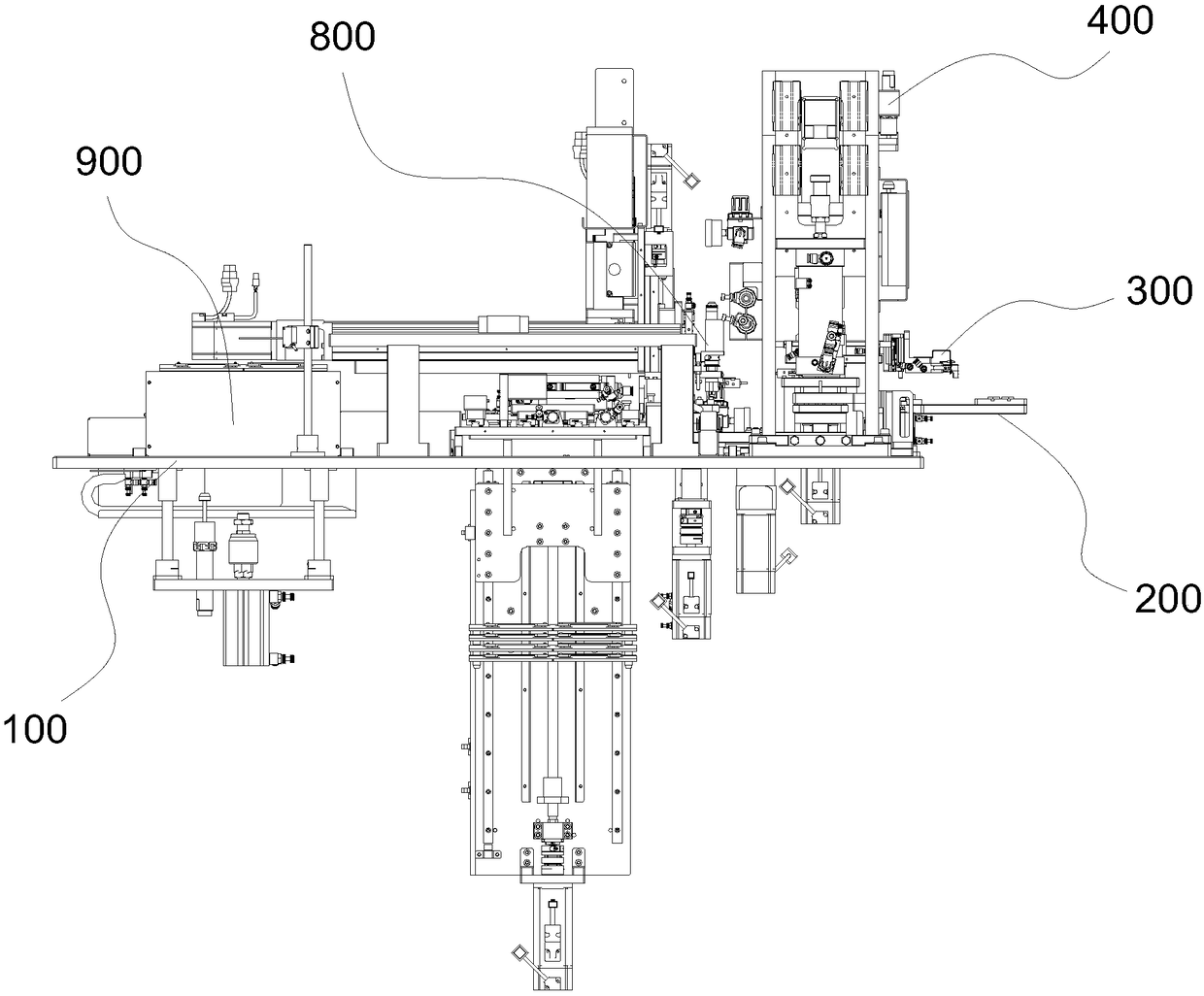

[0041] like Figure 1 to Figure 12 As shown, the whole system of the camera motor shell vibration separation and typesetting equipment includes an injection molding machine, a set of three-axis manipulator, a set of vibration separation system, a set of automatic pick-and-place typesetting system, and fully intelligently complete the integration of the machine and the injection molding machine. collaborative work.

[0042] The shake-off separation and typesetting equipment of the camera motor housing includes a frame 100, a feeding device arranged on the frame 100, a shake-off separation device, and a typesetting output device.

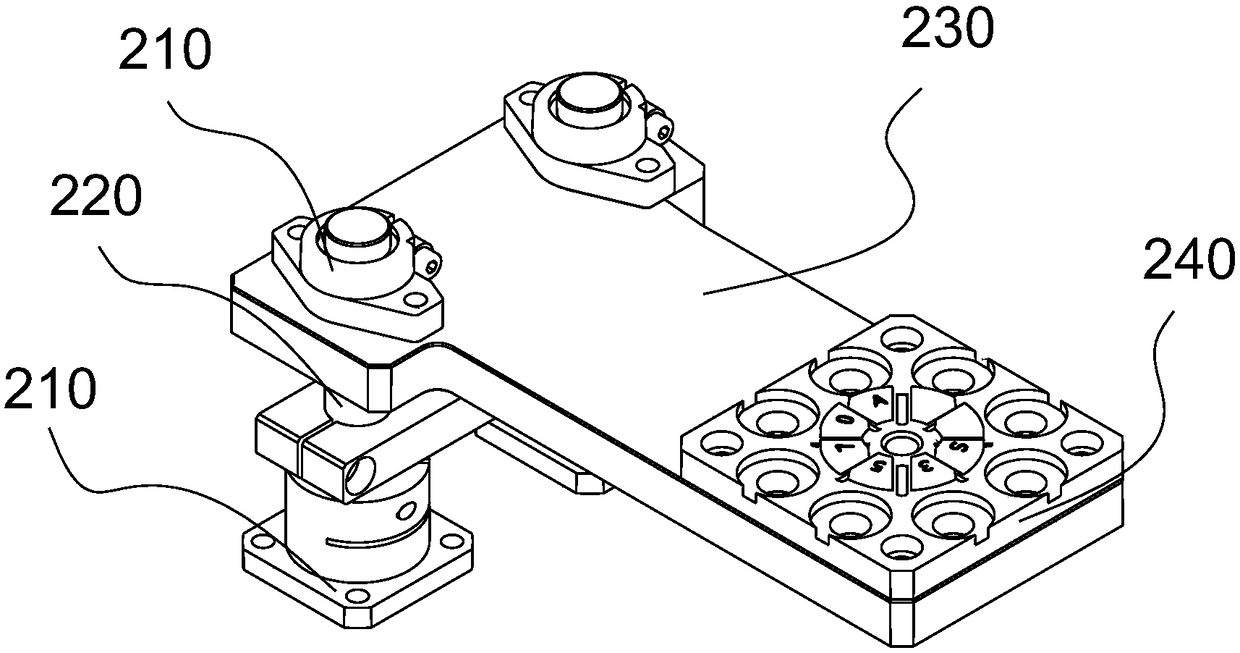

[0043]The feeding device includes a transfer mechanism 200, and a transfer mechanism 300 that cooperates with the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com