Converter dust removal ash iron recovery system and method based on KR desulfurization station

A converter dust removal and recovery system technology, applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve the problems of high investment, high operation and maintenance costs, reduce environmental pollution, reduce equipment investment, and reduce operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

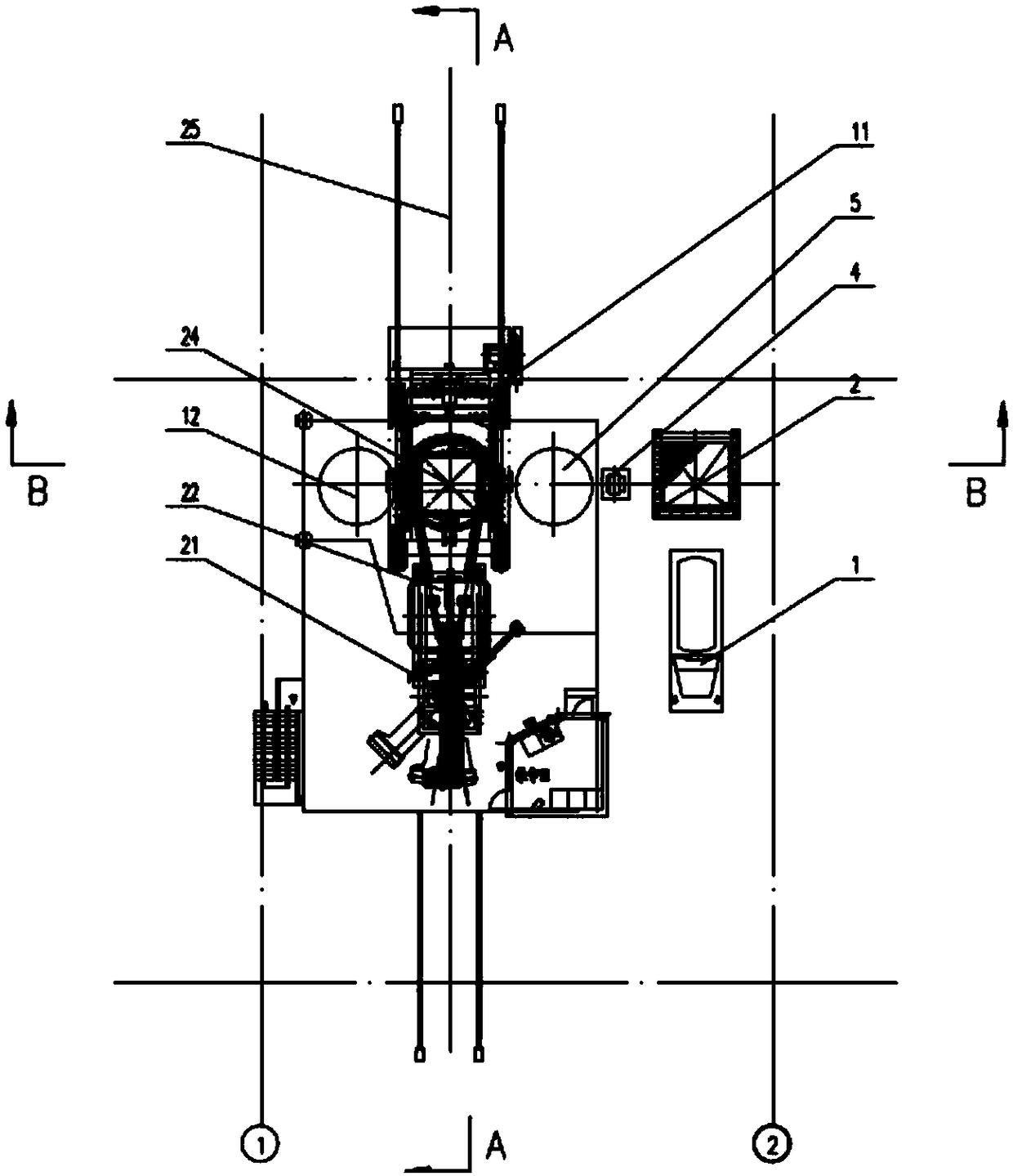

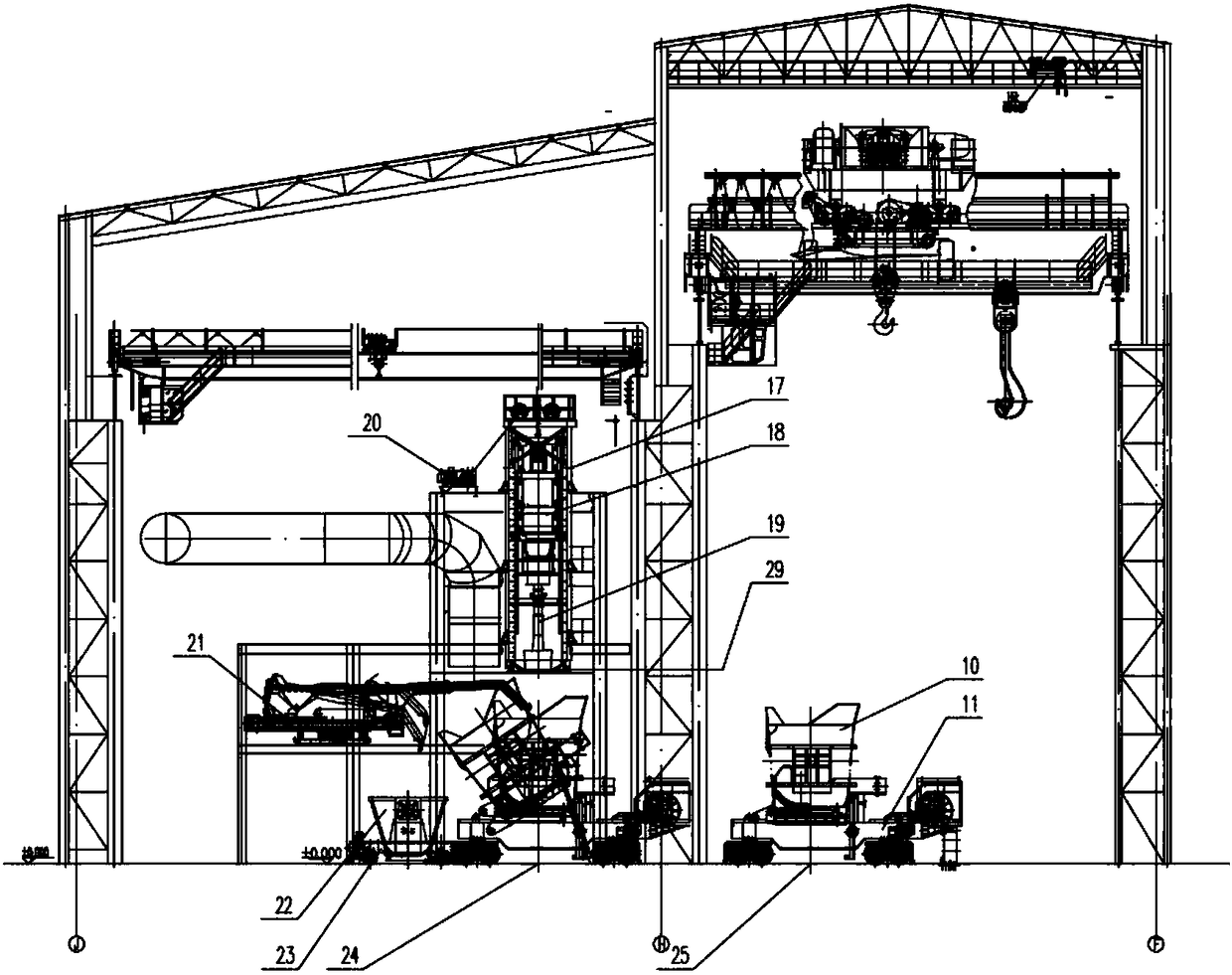

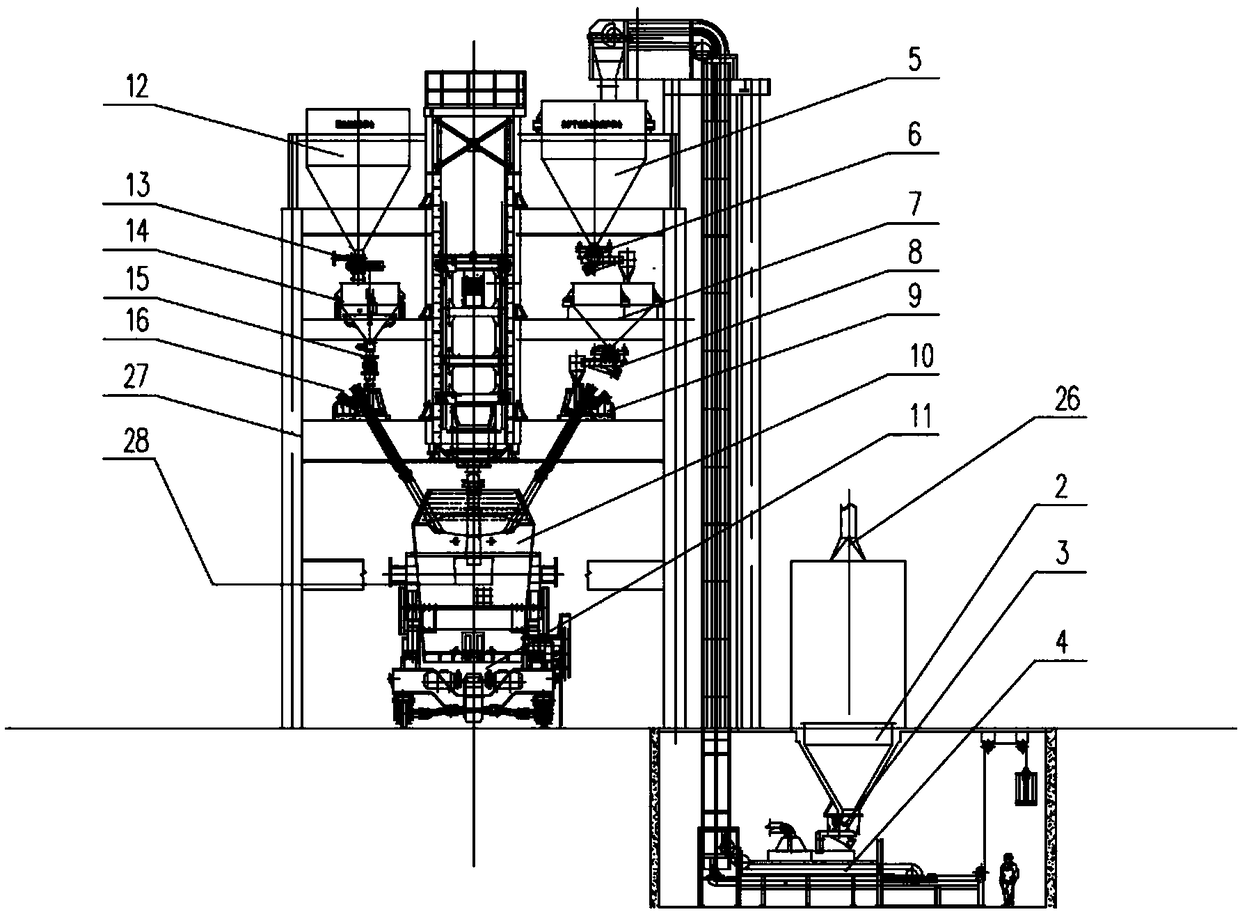

[0033] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] The KR desulfurization station is equipped with a desulfurization platform 27; in the desulfurization station, there are mostly desulfurization and slag removal positions for molten iron tanks, a stirring position for molten iron tanks, a tank position for molten iron tank seats and a position for hanging molten iron tanks. The present invention is described according to the same station for slag removal and stirring, and the same station for the hoisting tank and seat tank of the molten iron tank. Such as Figure 1 to Figure 3 A converter dedusting ash iron recycling system based on KR desulfurization station shown mainly includes a dedusting ash feeding device, a hot metal tank 10, a stirring device, a hot metal tank tipping car 11 and a slag remover 21, the dedusting ash feeding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com