Coke production method based on coking area fly ash and coal co-coking

A production method and co-coking technology, applied in coking ovens, petroleum industry, etc., can solve the problems of transshipment and stacking environmental pollution, high ash content, low utilization rate, etc., achieve good environmental and economic benefits, and solve the shortage of coking resources , The effect of reducing the cost of coking coal blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

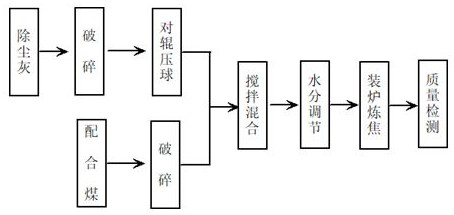

Method used

Image

Examples

Embodiment 1

[0046] Volatile VM from the coking area of the production plant d 9%, Ash A dAdd 13% dedusting ash to the crusher for crushing until the particle size is less than 0.4mm. Use medium-temperature asphalt as the binder, and add 4% of the mass of medium-temperature asphalt to the crushed dedusting ash. After mixing evenly, press it into a pillow-shaped material with a pressure of 5 t / cm at room temperature by a roller ball press, and set it aside. Will come from the production plant with a particle size of less than 6mm, A d =8%, VM d =26% of the basic mixed coal is added to the crusher for crushing, and the proportion of the crushed particle size is less than 3mm is 78%. Mechanically mix the pillow-shaped material made of dedusted dust with the crushed mixed coal to form a mixed material. The quality of the pillow-shaped material is 5% of the mixed coal, and 6% of water is added to the mixed material. The production coke oven carries out coking under a certain heating syste...

Embodiment 2

[0049] Volatile VM from the coking area of the production plant d 10%, Ash A d Add 12% dedusting ash to the crusher for crushing until the particle size is less than 0.4mm. Use medium-temperature asphalt as the binder, and add 3% of the mass of medium-temperature asphalt to the crushed dedusting ash. After mixing evenly, press it into a pillow-shaped material with a pressure of 4t / cm at room temperature through a roller press ball machine for future use. Will come from the production plant with a particle size of less than 6mm, A d =7%, VM d = 27% of the basic mixed coal is added to the crusher for crushing, and the proportion of the crushed particle size is less than 3mm is 76%. The pillow-shaped material pressed from dedusting ash is mechanically mixed with the crushed mixed coal to form a mixed material. The quality of the pillow-shaped material is 6% of the mixed coal, and 5% of water is added to the mixed material. The production coke oven carries out coking under a...

Embodiment 3

[0052] Volatile VM from the coking area of the production plant d 11%, Ash A d Add 11% dedusting ash to the crusher for crushing until the particle size is less than 0.4mm. Use high-temperature asphalt as a binder, and add 4% high-temperature asphalt by mass to the crushed dedusting ash. After mixing evenly, press it into a pillow-shaped material with a pressure of 5t / cm at room temperature by a roller ball press for future use. Will come from the production plant with a particle size of less than 6mm, A d =6%, VM d =28% of the basic mixed coal is added to the crusher for crushing, and the proportion of the crushed particle size is less than 3mm is 75%. The pillow-shaped material pressed from dedusting ash is mechanically mixed with the blended coal after crushing to form a mixed material. The mass of the pillow-shaped material is 7% of the mixed coal mass, and 4% of water is added to the mixed material. The production coke oven carries out coking under a certain heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com