Mountain road filling and excavation junction roadbed structure and construction method thereof

A technology for junctions and mountainous areas, applied in infrastructure engineering, roads, roads, etc., can solve problems such as poor applicability, high requirements for lap joints, and large changes in construction methods, so as to eliminate insufficient rolling, speed up construction, Guaranteed load bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

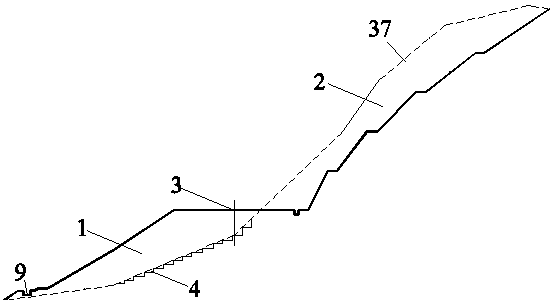

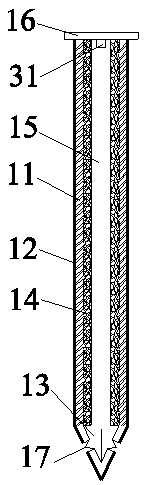

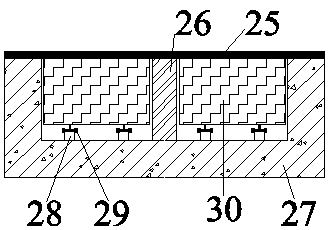

[0035] like Figure 1-6 As shown, the subgrade structure at the junction of filling and excavation of mountainous highways of the present invention comprises a filling section 1, an excavation section 2 and a transition section 3 at the junction of filling and excavation. The transition section 3 at the excavation junction is provided with a drainage system 18 at the junction of filling and excavation. The drainage system 18 at the junction of filling and excavation includes a horizontal drainage blind ditch 8 assembled with a replaceable drainage body, a vertical through drainage blind ditch 20, and a water-permeable and isolated drainage ditch at the junction of filling and excavation. The combined transition section 21 of the water layer, the combined transition section 21 of the permeab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com