Constructing method for continuous bearing layer of super long socketed pile in bead-like karst area

A karst area and bearing layer technology, applied in sheet pile wall, building, infrastructure engineering and other directions, can solve the problems of construction difficulties, omission of pile foundation in the bearing layer at the bottom of the pile, string holes, etc. The effect of increasing the pile bottom elevation and shortening the design pile length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

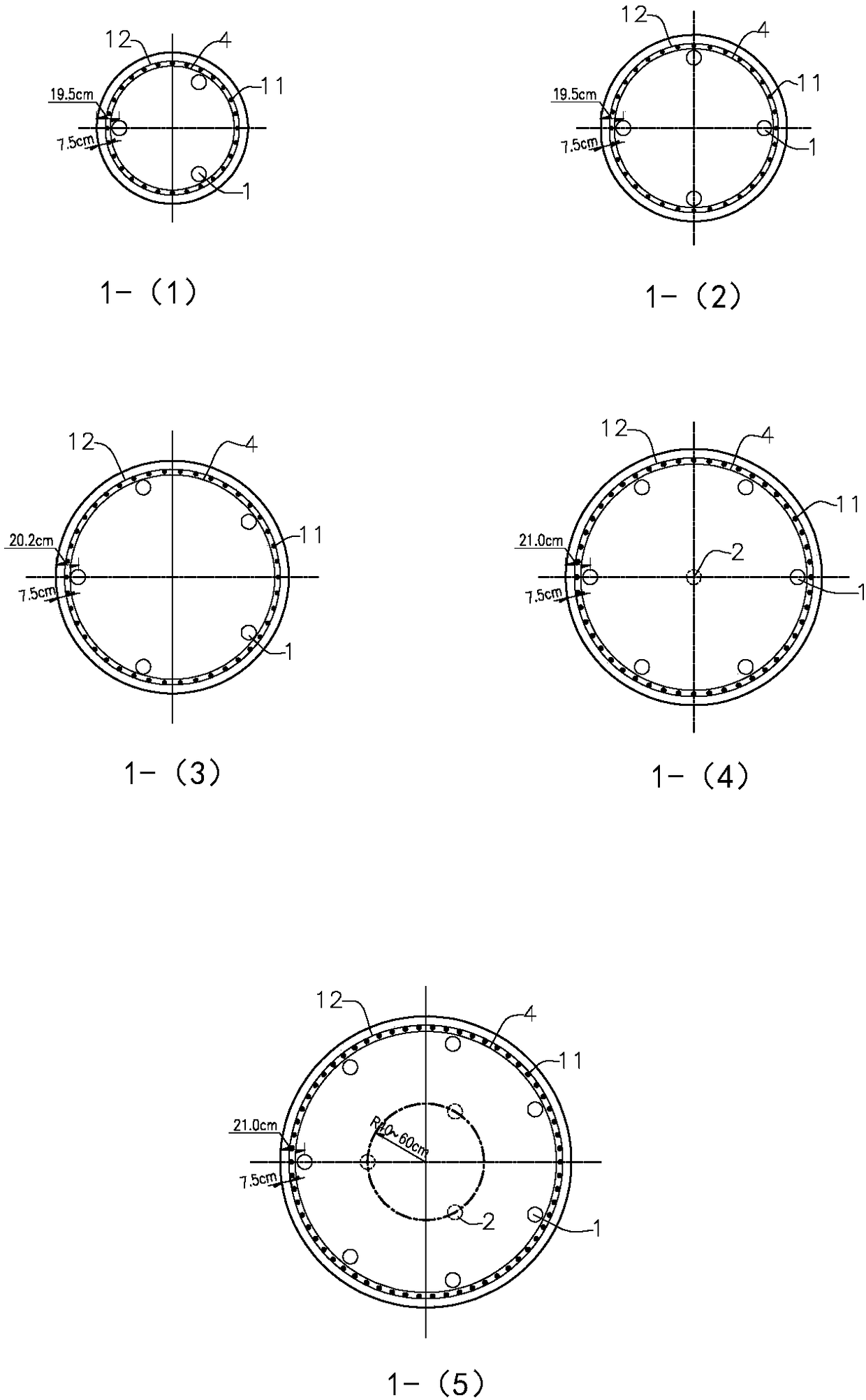

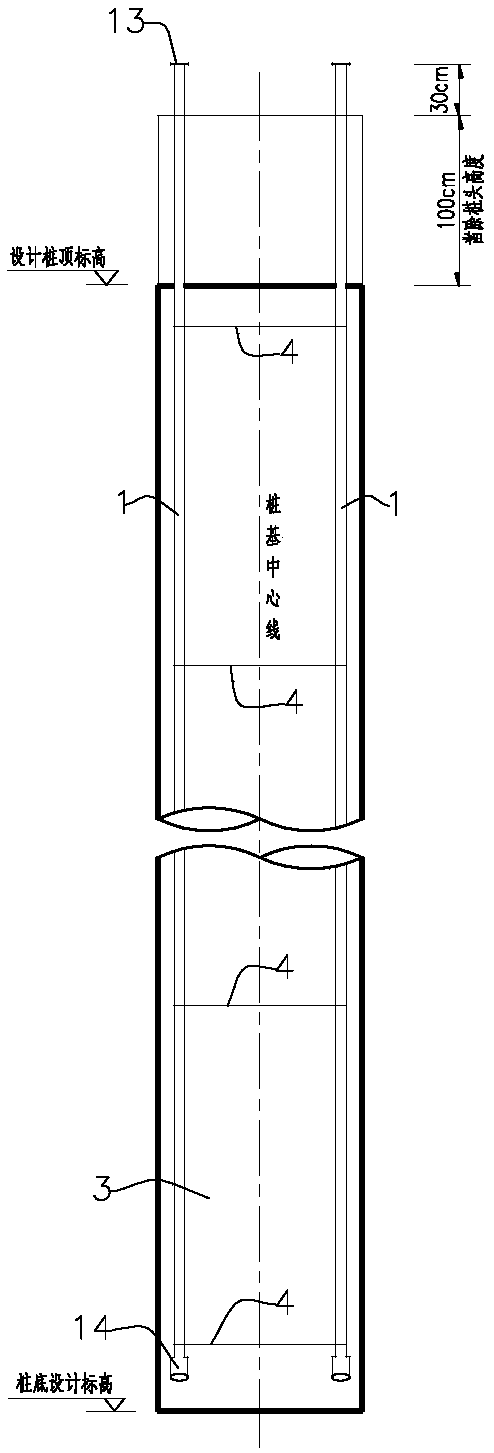

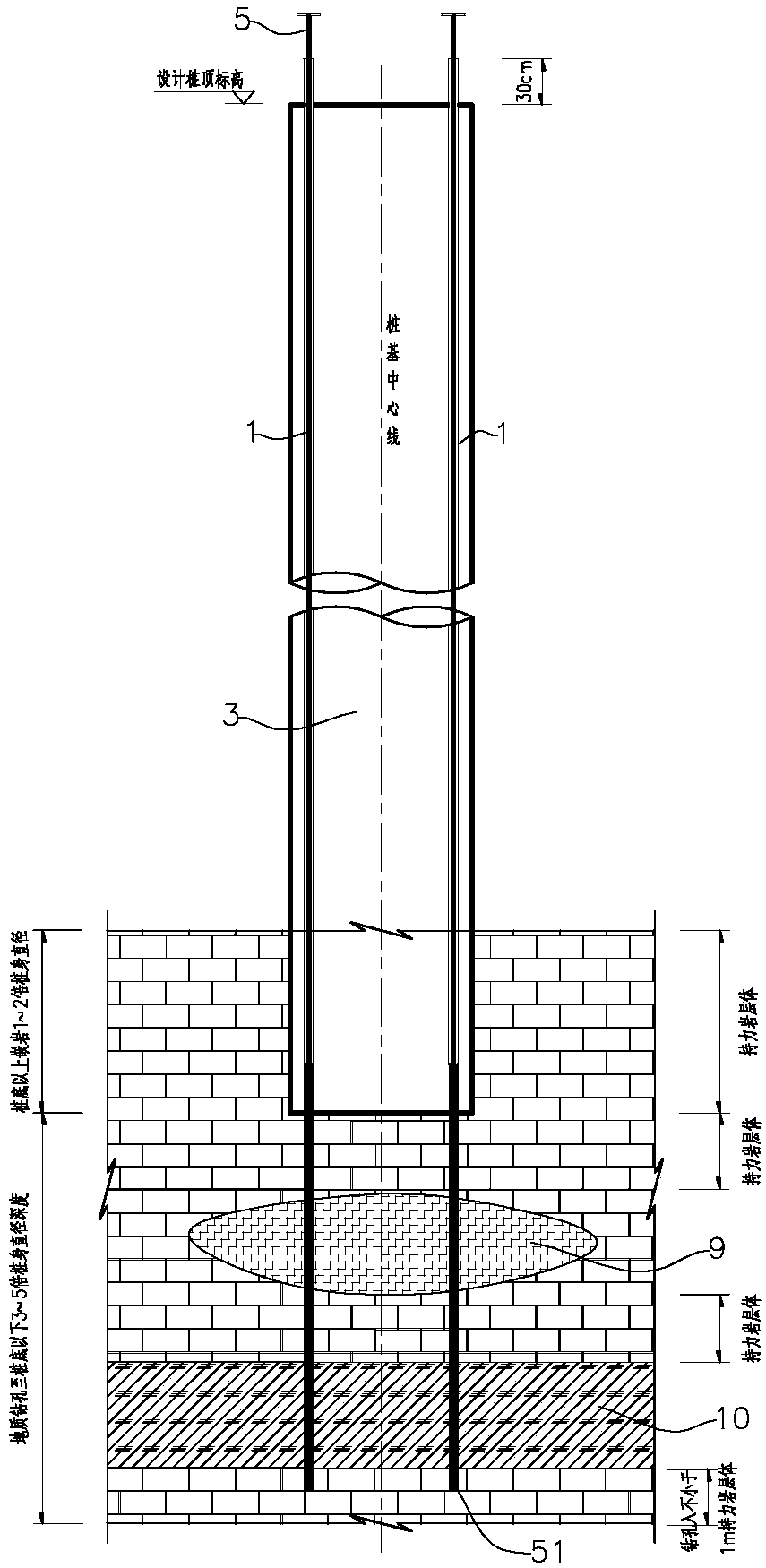

[0060] refer to Figure 1 to Figure 10 , a method for constructing a continuous bearing layer of super-long rock-socketed piles in a beaded karst area according to an embodiment of the present invention, which mainly includes the following steps:

[0061] S1. Through the multi-holes of single piles, investigate in detail the specific vertical distribution of the geological rock structure and karst caves at each pile position, and determine the design elevation and pile length of each pile body through active optimization design;

[0062] S2. A number of vertical through-length steel pipes are evenly pre-embedded along the circumference of the pile inside the reinforcement cage of each pile body;

[0063] S3. Adopt the method of drilling and coring, use the steel pipe channel to carry out supplementary investigation on the rock formation geology of the bearing layer at the bottom of each pile, and combine the detailed investigation situation to finally determine whether there i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com