A sharp ridge cutting tooth

A technology of cutting teeth and sharp ridges, which is applied in drilling equipment, construction, earthwork drilling and mining, etc., can solve the problems of round tooth chipping resistance and wear resistance, drill bit failure, increase the operation time of drilling and tripping, and improve the anti-abrasion The ability to prolong the service life and improve the efficiency of rock breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

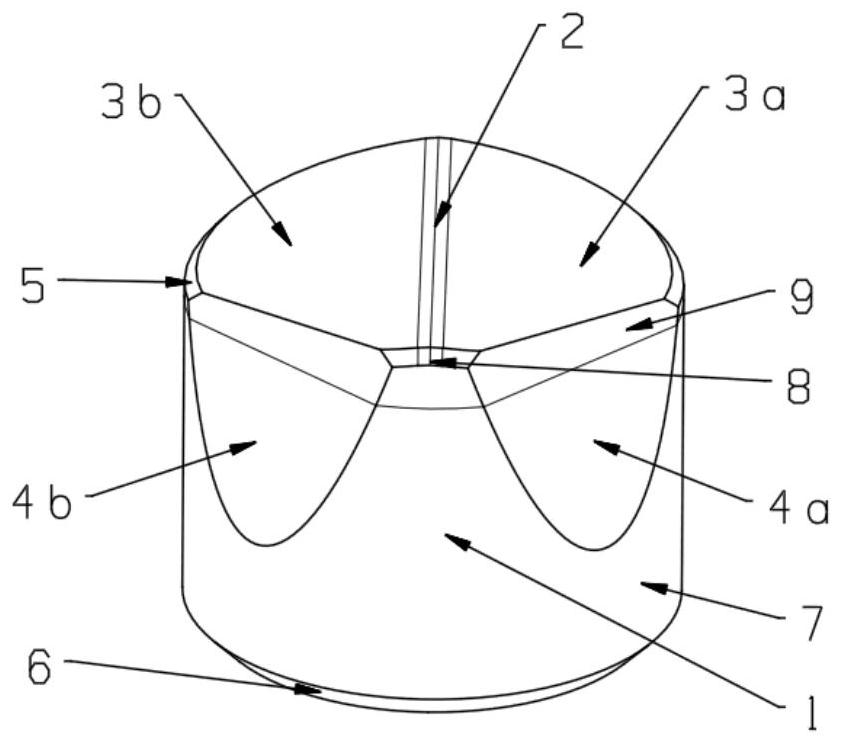

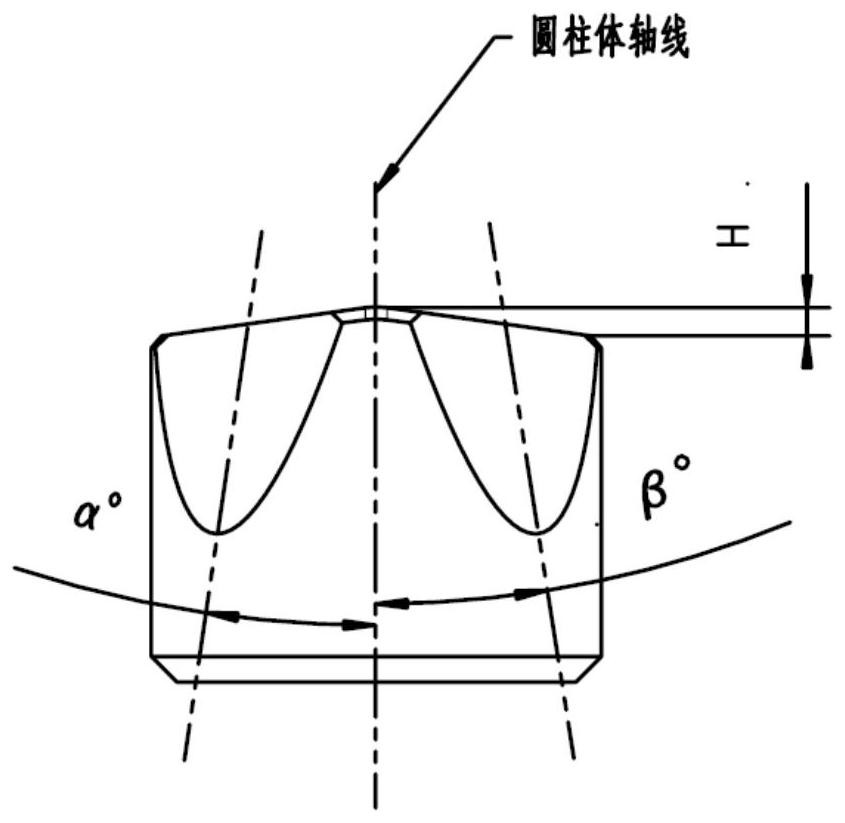

[0027] Such as figure 1 , 2 As shown, the present embodiment provides a ridge-shaped cutting tooth, which includes a cylindrical body 1, a tooth end surface 3 is provided on the upper end of the body 1, a tooth top surface 8 is provided at the outer edge of the upper end portion, and a tooth top surface 8 is provided on the side wall. The tooth side surface 4, the bottom is provided with the bottom surface of the body, and the tooth end surface 3 includes two obliquely intersecting transition surfaces (3a, 3b). A convex ridge 2 is formed at the intersection of the inclined planes, the outer end of the convex ridge meets the tooth top surface 8, and the inner end meets the upper end surface of the cylindrical body; the tooth flank 4 includes two wedge surfaces (4a, 4b), the upper ends of the two offset wedge surfaces (4a, 4b) extend to the tooth end surface, form a sharp ridge with the tooth top surface and the corresponding convex ridge, and the lower end of the offset wedge ...

Embodiment 2

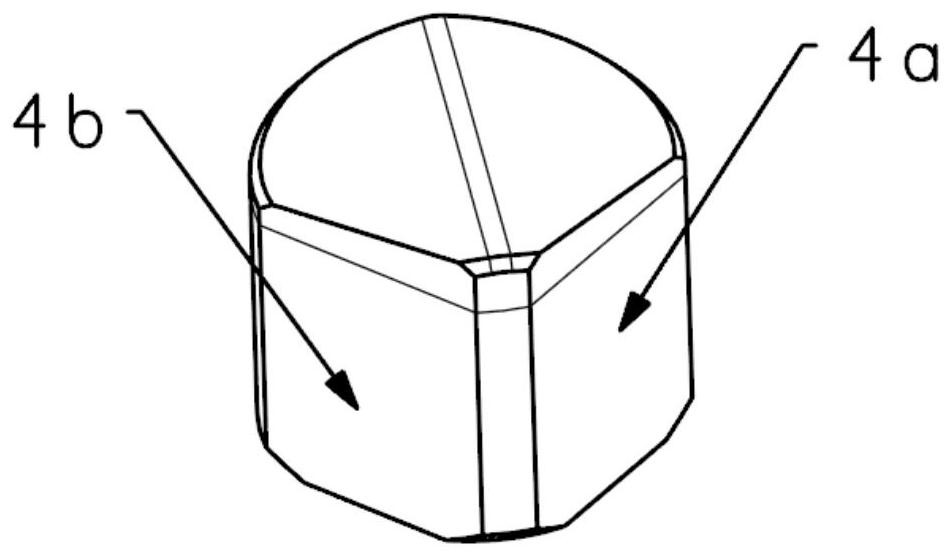

[0034] Such as image 3 As shown, the second embodiment is basically the same as the first embodiment, except that the lower end of the wedge surface extends to the bottom surface of the body, that is, the angle formed by the two wedge surfaces (4a, 4b) and the axis of the cylindrical body Both α and β are 0°, that is, the two wedge surfaces are parallel to the central axis of the body.

Embodiment 3

[0036] The third embodiment is basically the same as the first embodiment, except that the transition surfaces 3a and 3b are asymmetric, the transition surface 3a is a convex arc surface, the transition surface 3b is a concave arc surface, and the two wedge surfaces (4a, 4b) are As for the asymmetric wedge surface, the angle β formed by the wedge surface 4a and the axis of the cylinder body is 30°, and the angle α formed by the wedge surface 4b and the axis of the cylinder body is 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com