Slurry fixing device of hydraulic slurry cutting machine and hydraulic slurry cutting machine

A technology of fixing device and cutting machine, which is applied in the field of papermaking machinery, can solve the problems of cumbersome pulp cutting, high friction force of cutter, high labor intensity, etc., achieve good promotion and use value, reduce running resistance, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

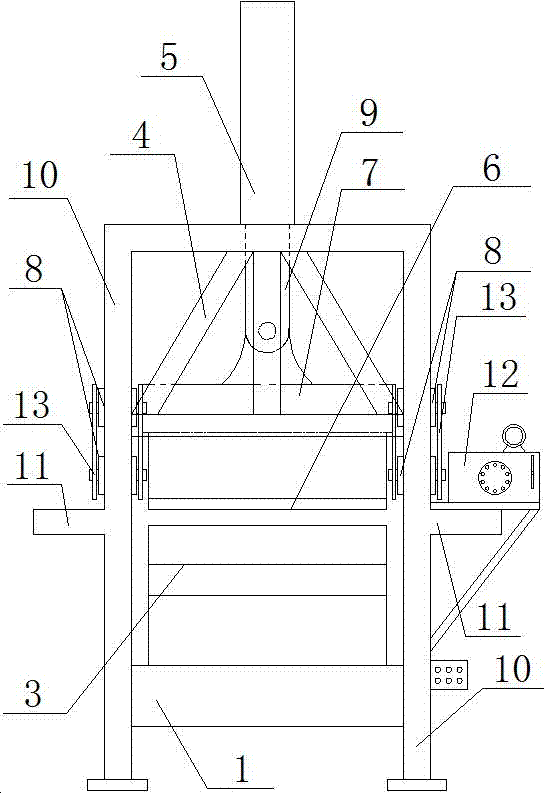

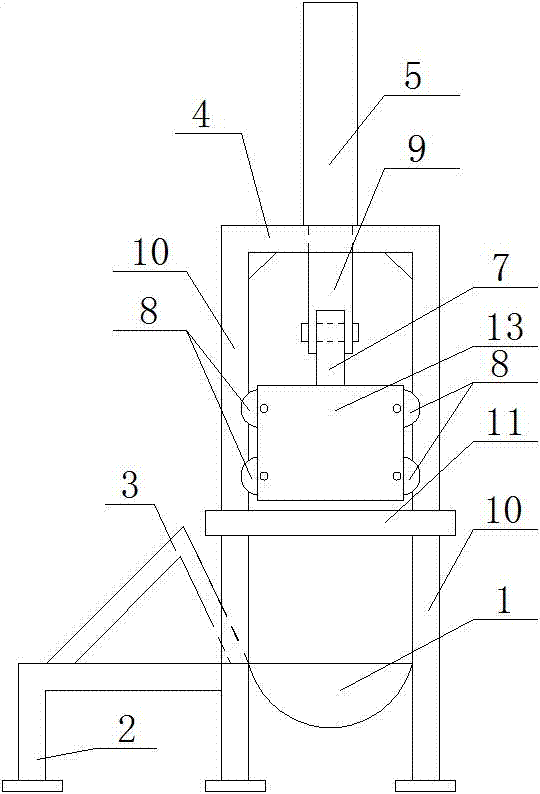

[0027] The slurry fixing device of the hydraulic slurry cutting machine of the present invention, the slurry fixing device includes a workbench 1, a feeding platform 2 and a slurry retaining frame 3, and the workbench 1 is fixed at the lower center of the hydraulic slurry cutting machine; The workbench 1 is a workbench 1 with a semicircular arc structure with an upper opening; the feeding platform 2 of the L-shaped structure is arranged at the inlet of the workbench 1, and the upper surface of the feeding platform 2 is arranged parallel to the ground, and the triangular structure can be The movable slurry stop frame 3 is set on the feeding platform 2; the upper surface of the feeding port of the working table 1 and the upper surface of the feeding platform 2 are set on the same plane, and the working table 1 and the feeding platform 2 are fixed by welding connected.

Embodiment 2

[0029] The hydraulic slurry cutting machine of the present invention includes a frame 4, the upper end of the frame 4 is provided with a hydraulic cylinder 5, the middle part of the frame 4 is provided with a transmission connection device, the lower part of the transmission connection device is connected with the cutter 6, and the lower end of the frame 4 A slurry fixing device is provided; the slurry fixing device is a slurry fixing device of any hydraulic slurry cutting machine in embodiment 1; the slurry fixing device is arranged at the bottom of the hydraulic slurry cutting machine; the transmission connection device includes a connecting Bracket 7 and guide wheel 8, the top of connecting bracket 7 of fan-shaped structure is connected with the piston rod 9 of hydraulic cylinder 5 by hinge; Connected to the inside of each column 10 of the frame 4; the connecting bracket 7 includes a guide wheel support plate 13, the guide wheel support plate 13 is located at the two ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com