Variable damping squeeze-film damper for aeroengine

A technology of squeezing oil film damping and aero-engines, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc. It can solve the problems of parts processing and assembly errors, and the oil film gap cannot meet the design requirements, so as to save manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

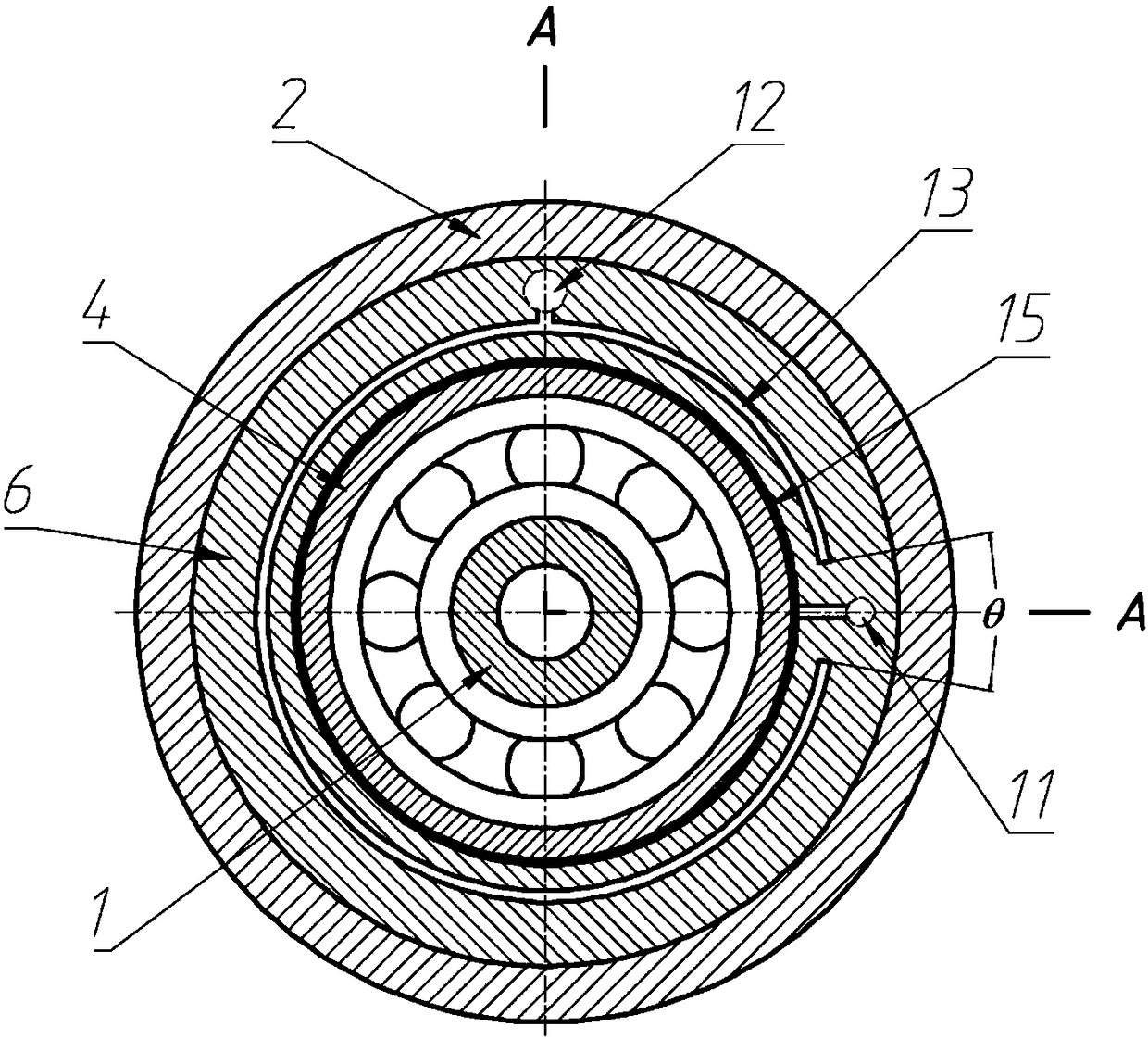

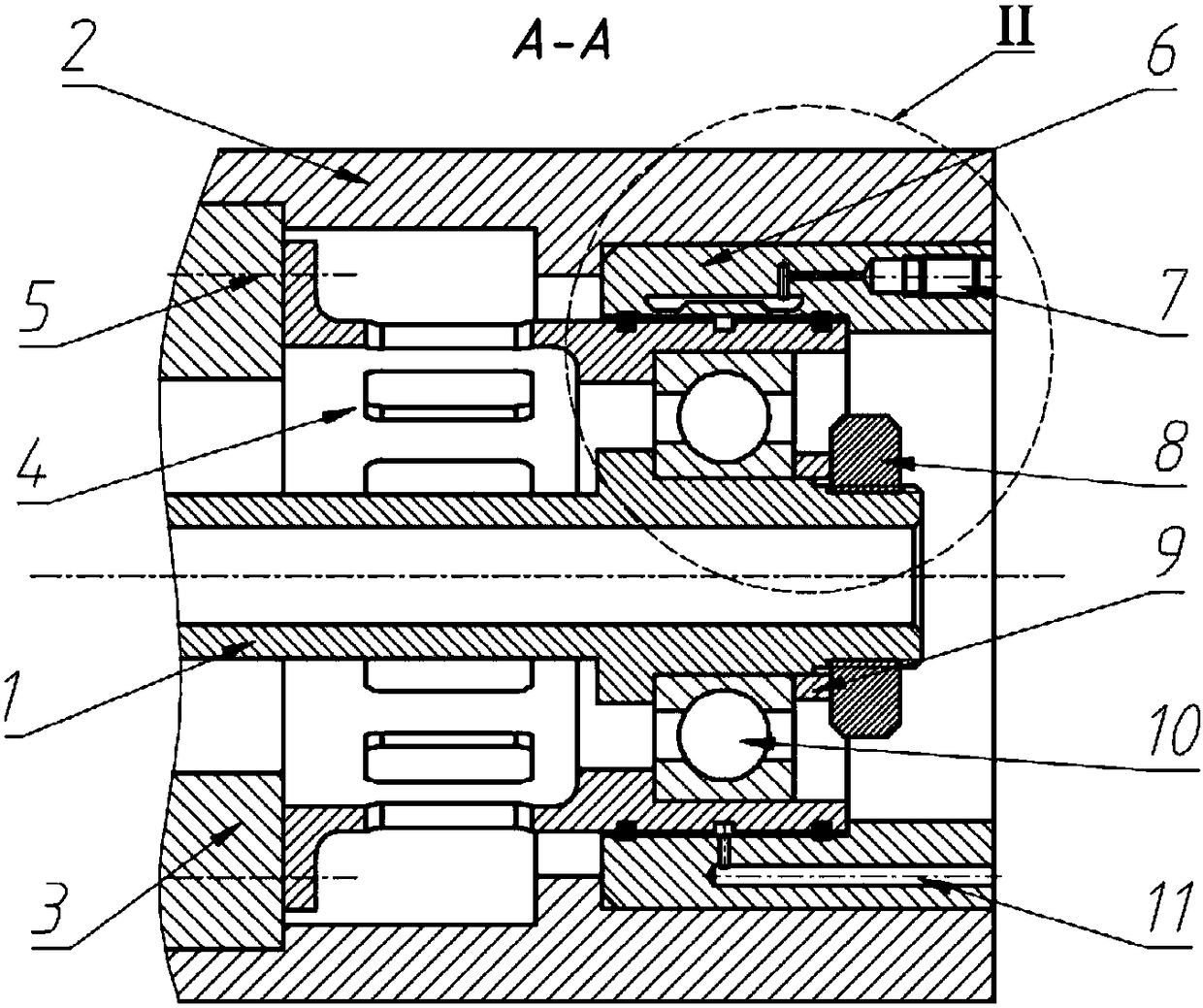

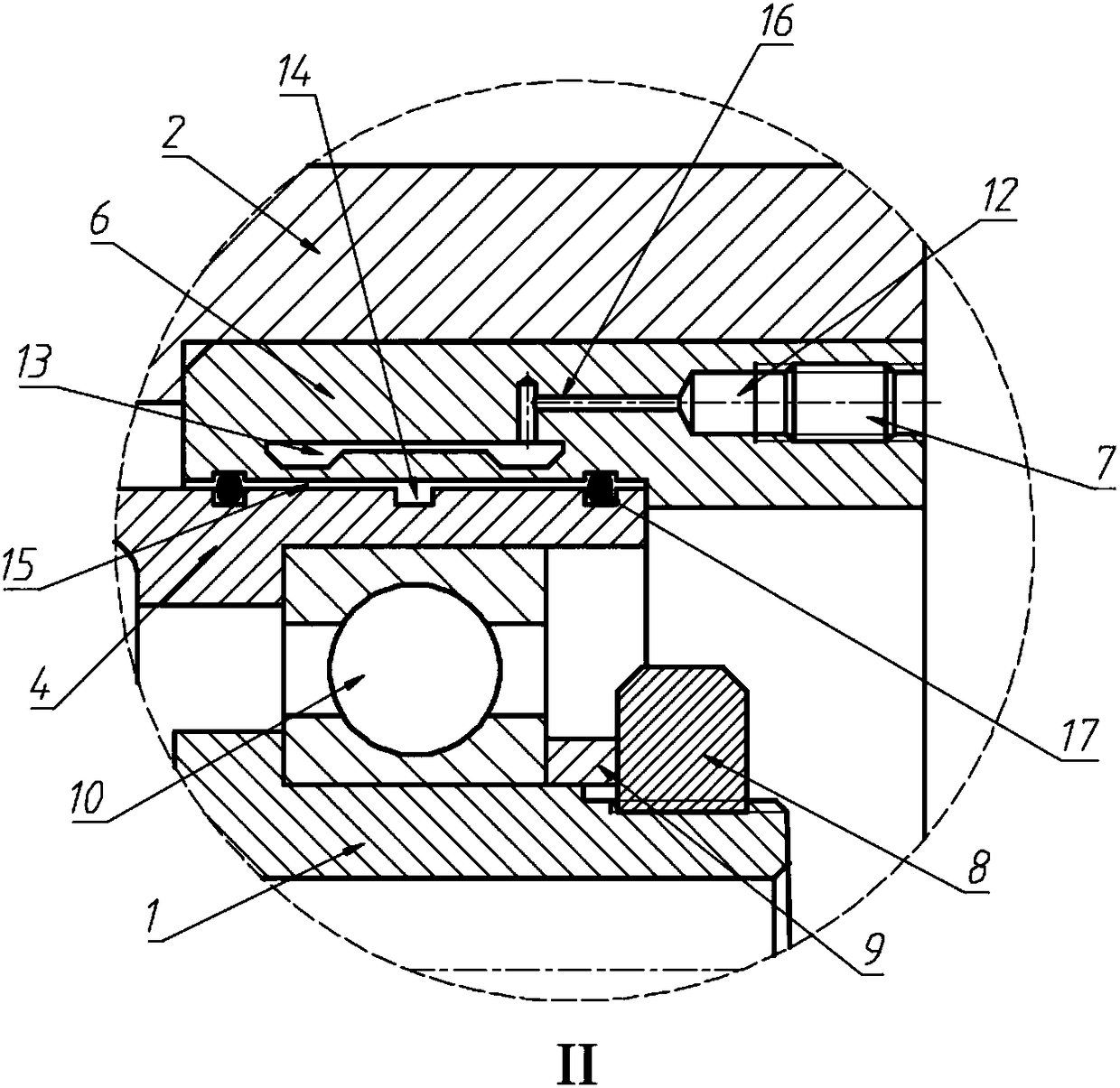

[0023] Such as Figure 1 to Figure 3 As shown, a variable damping squeeze oil film damper for an aero-engine provided by the present invention includes an elastic support 4, a variable damping base 6, a hydraulic oil chamber 13, a hydraulic oil flow channel 16, a hydraulic adjustment screw 7 and an extrusion oil film15.

[0024] Such as figure 2 and image 3 As shown, the elastic support 4 is connected with the elastic support installation base 3 through the installation screws 5, and the elastic support installation base 3 is assembled with the equipment base 2 without contact with the rotor 1; The outer ring of the rolling bearing 10 is assembled, and the rolling bearing 10 is axially positioned through the steps on the inner wall. The outer wall of the elastic support 4 is circumferentially provided with two grooves equipped with O-rings 17 , and the area betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com