Heat dissipater device with heat-isolation layer

A technology of radiator and heat insulation layer, applied in the direction of heat exchanger type, indirect heat exchanger, heat transfer modification, etc., can solve the problems of slow water cooling process, low efficiency, easy temperature accumulation, etc., and achieve fast cooling speed. , Complete heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

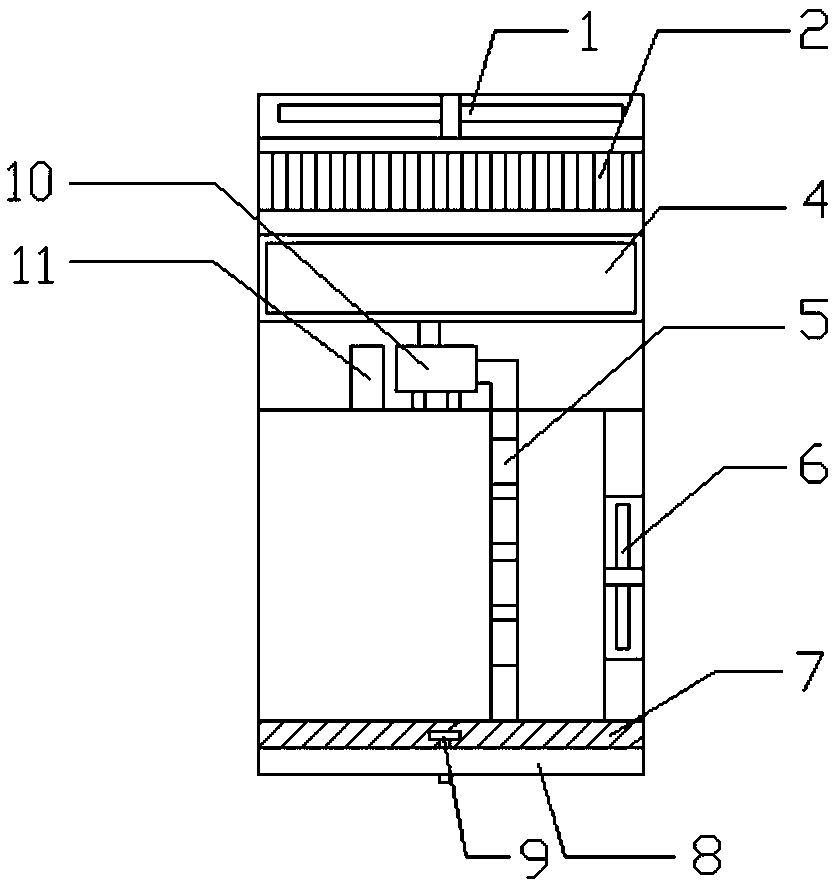

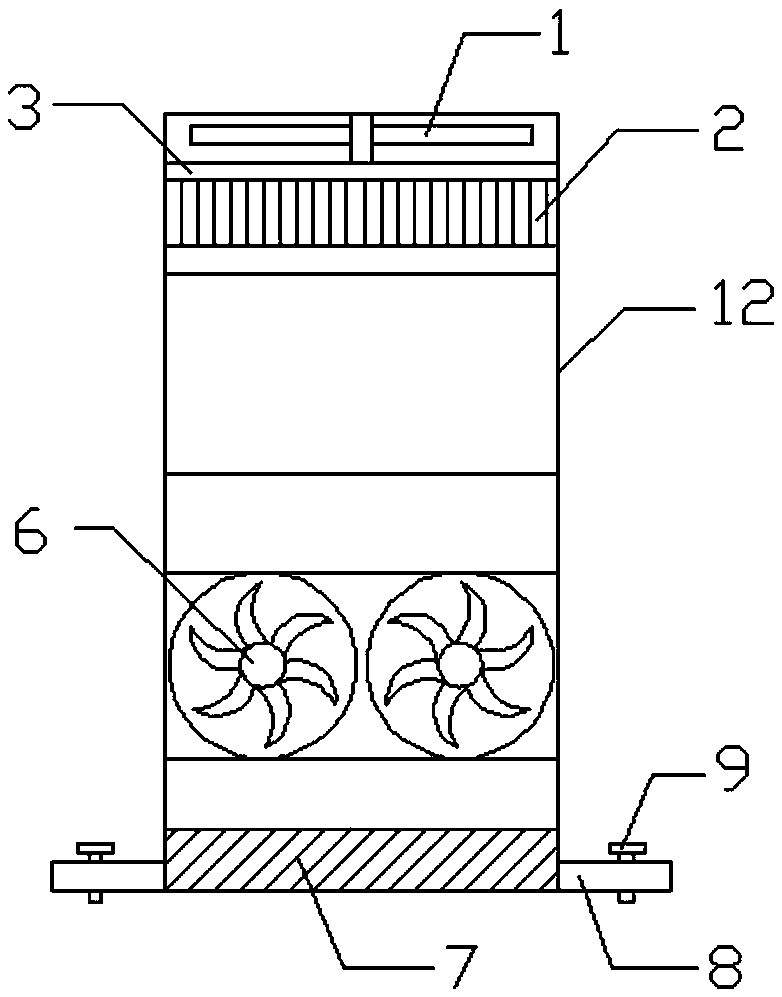

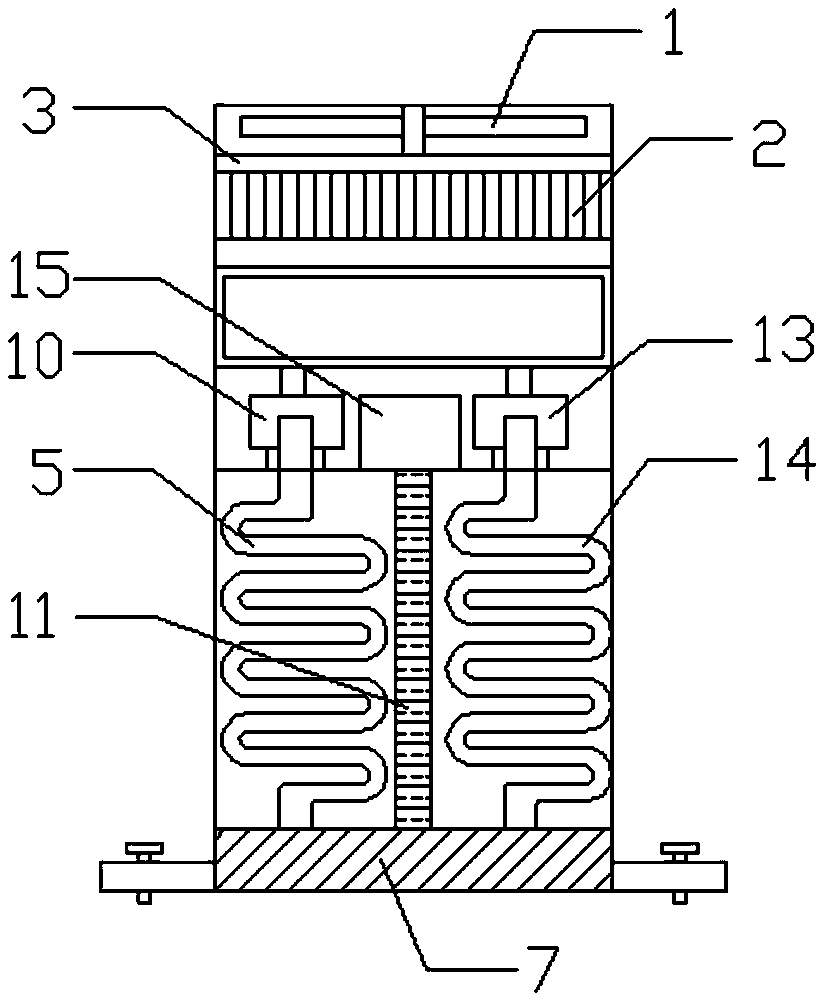

[0018] Example: such as Figure 1-3 As shown, it includes a water tank cooling fan 1, a fixed frame 3 is arranged under the water tank cooling fan 1, an insert radiator 2 is arranged under the fixed frame 3, and a water supply layer 12 is arranged under the insert radiator 2, The inside of the water supply layer 12 is provided with a copper water tank 4, a first small water pump 10 and a second small water pump 13 are arranged below the copper water tank 4, and a small water pump 10 and a second small water pump 13 are arranged between the first small water pump 10 and the second small water pump 13. There is a power source 15, a first serpentine pipe 5 is connected below the first small water pump 10, a second serpentine pipe 11 is arranged below the second small water pump 13, and the first serpentine pipe 5 is connected to the first serpentine pipe 5. The two serpentine tubes 14 are separated by a vacuum insulation panel 11. Two main cooling fans 6 are arranged on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com