Thermocouple device for measuring tin bath temperature in float glass furnace

A technology of float glass and thermocouple, which is applied in the direction of measuring devices, electric devices, measuring heat, etc., can solve the problems of inaccurate measured values, inconvenient temperature measurement, etc., reduce processing difficulty, speed up thermal response time, good Effects of corrosion resistance and thermal insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

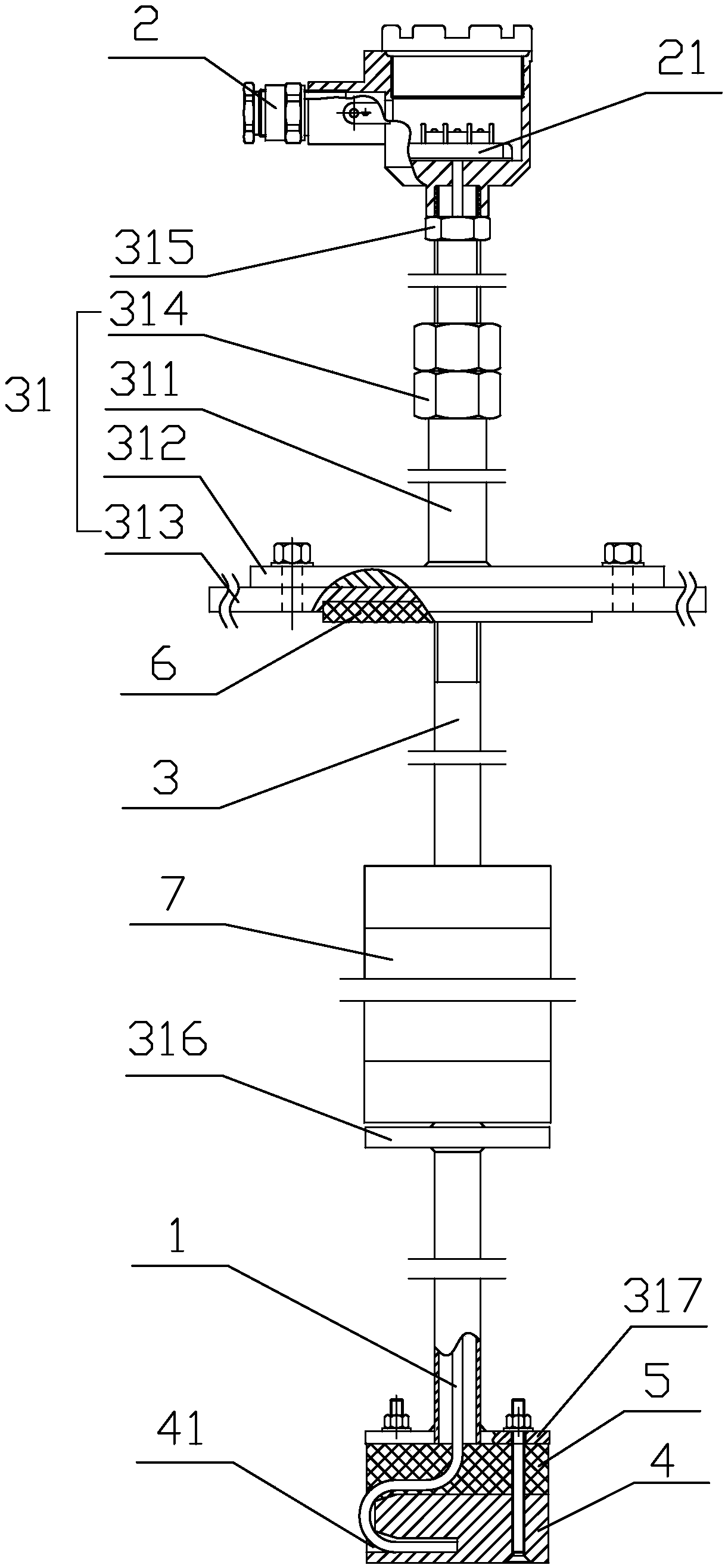

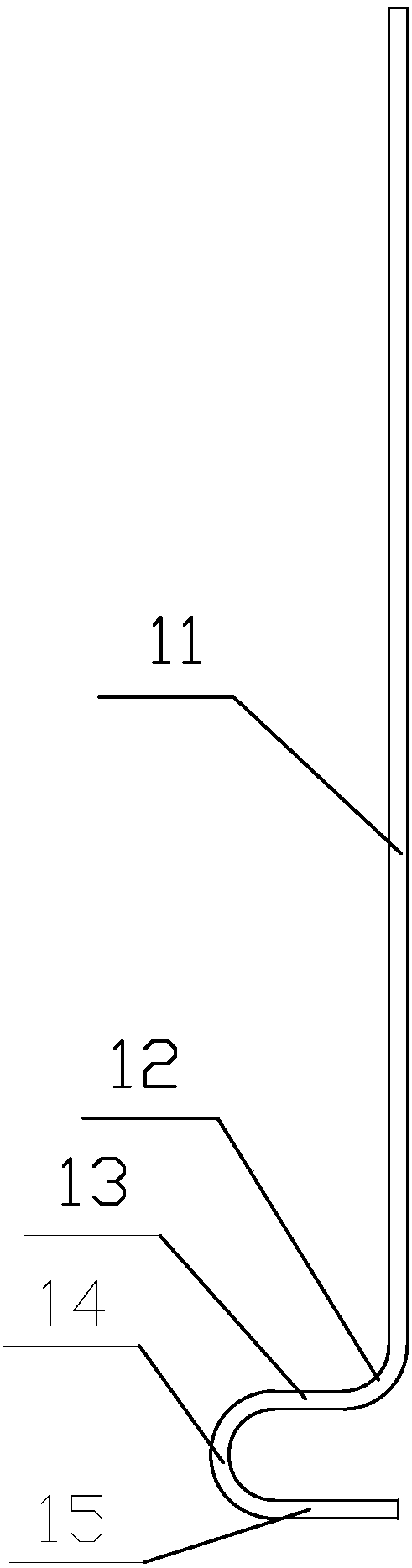

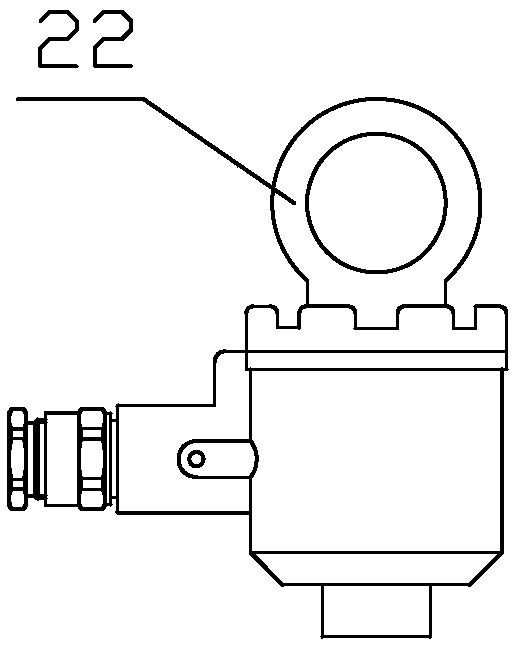

[0029] Such as figure 1 , figure 2 with Figure 4 As shown, a kind of thermocouple device for measuring the temperature of the tin bath in the float glass melting furnace of the present invention includes: an armored thermocouple 1 for temperature measurement, and a terminal block 21 is built inside for armoring The junction box 2 of the temperature output measured by the thermocouple 1 and the support tube 3 connected to the junction box 2, the armored thermocouple 1 is placed in the support tube 3, as Figure 4 The two wires of the shown armored thermocouple are electrically connected to the terminal block 21 (a group of armored thermocouples are shown in the figure), and the lower end of the support tube 3 is also connected with a thermocouple protective sheath 4 made of graphite and placed The heat insulating block 5 between the support tube 3 and the thermocouple protective cover 4, the thermocouple protective cover 4 has an accommodation cavity 41, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com