Battery pole piece testing method and die for preparing battery pole piece

A battery pole piece and testing method technology, which is applied in the field of failure analysis research of lithium-ion batteries, can solve problems such as current collector damage, dressing residue, consistency, and repetitive battery pole piece capacity value difficulties, and achieve a simple test method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

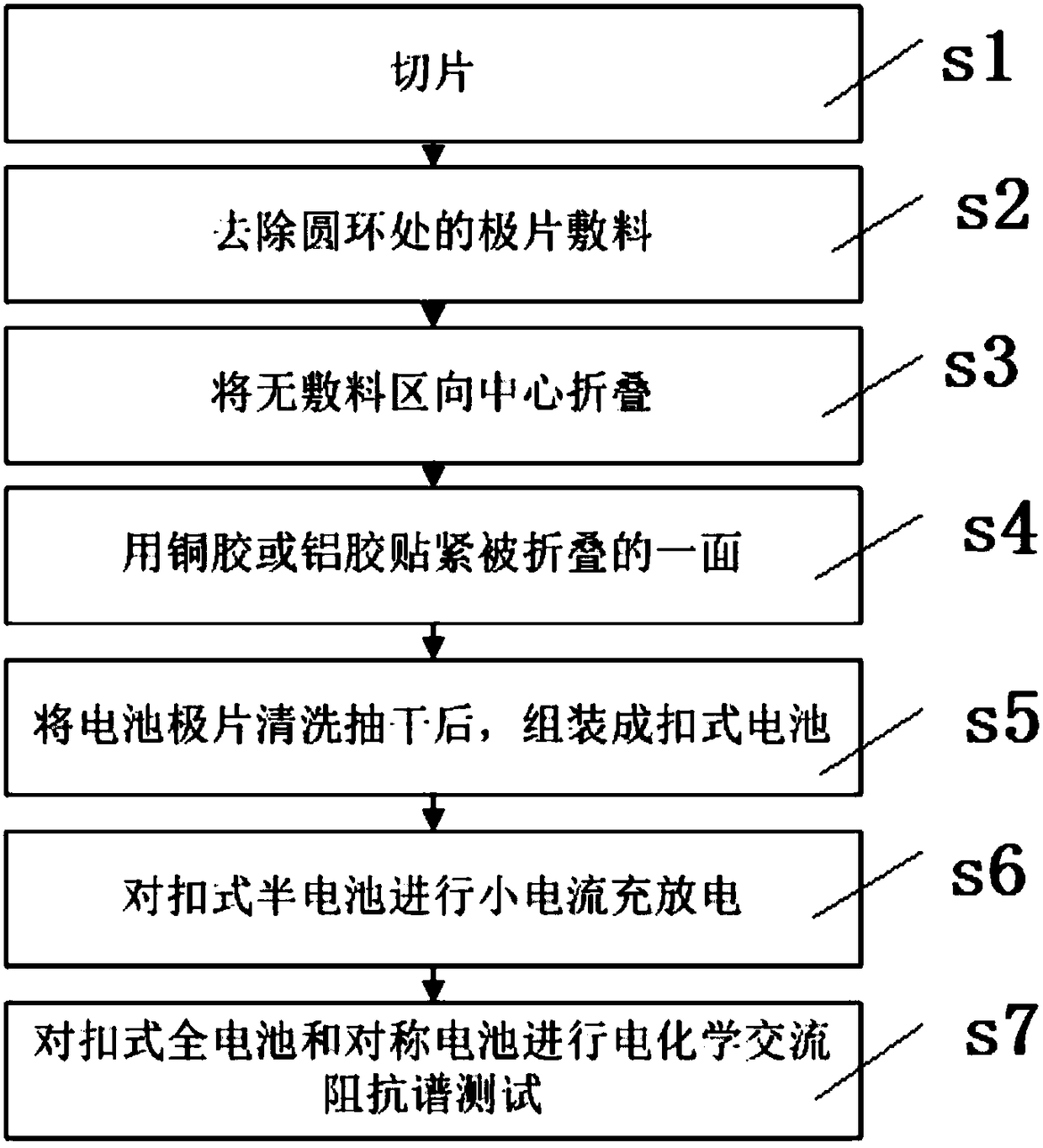

Method used

Image

Examples

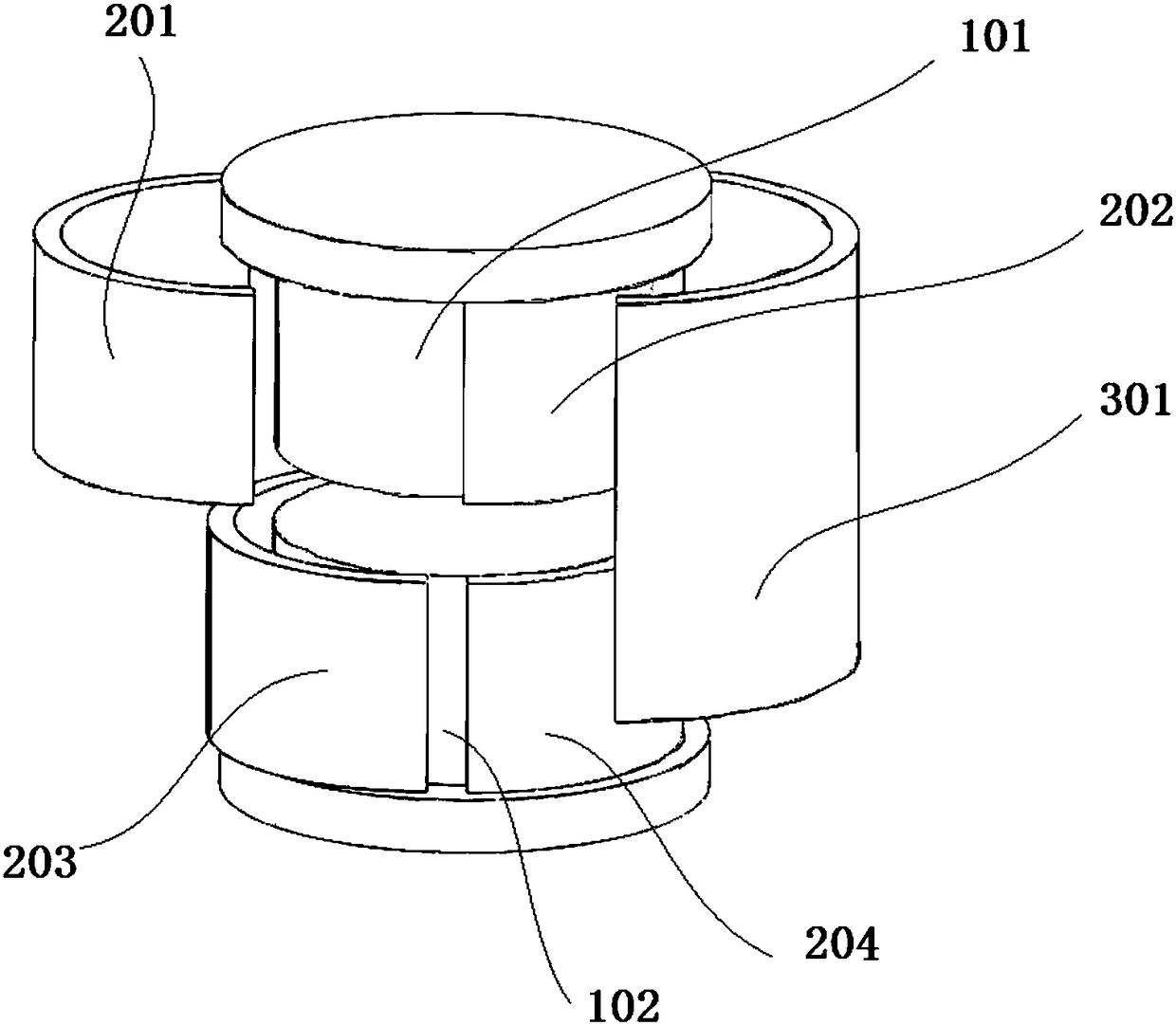

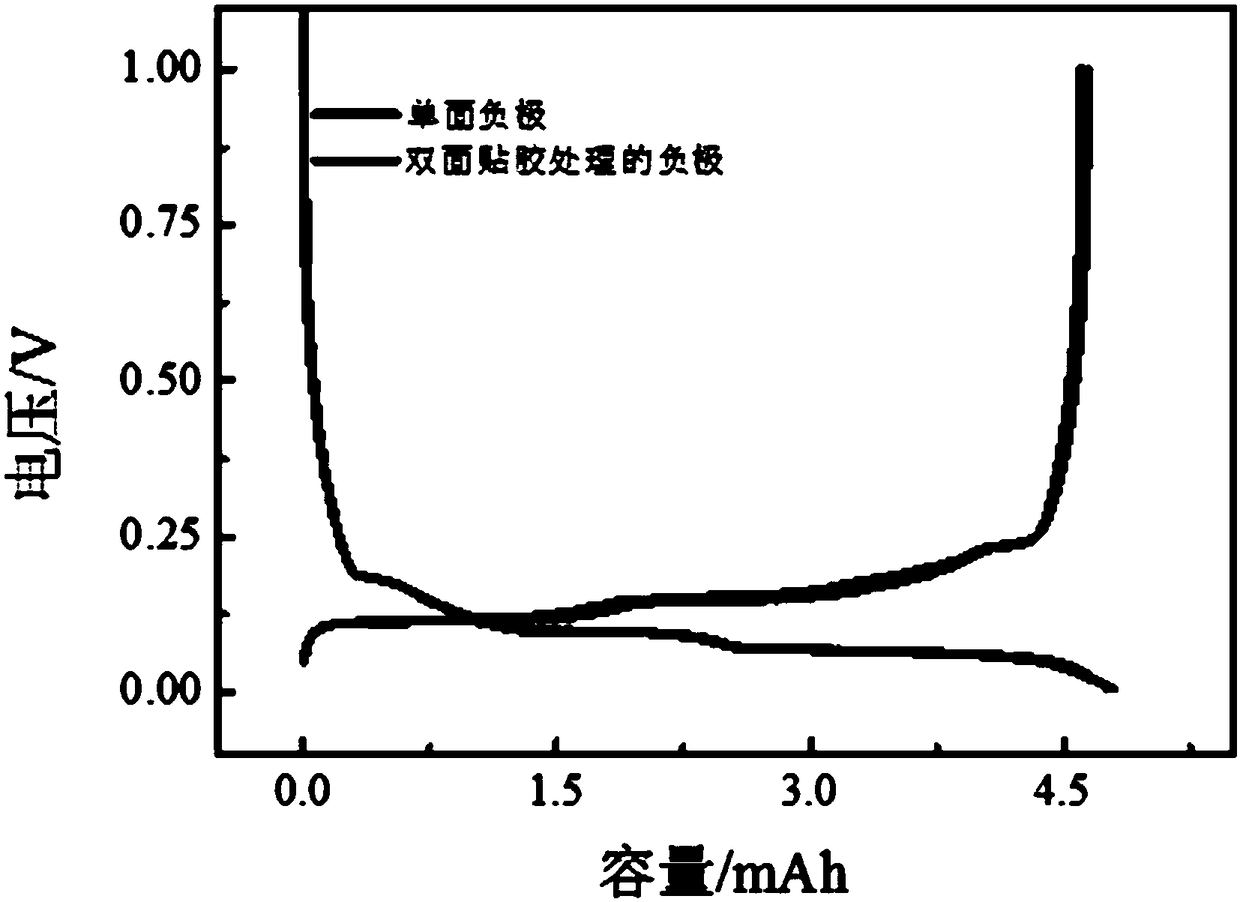

Embodiment 1

[0051] The fully charged state (LiNi 0.6 co 0.2 mn 0.2 o 2 +LiMn 2 o 4 ) / graphite pouch battery for disassembly. The disassembled double-sided positive and negative electrodes were cut into circular pole pieces with a diameter of 16 mm. The disassembled single-sided positive and negative electrodes were cut into circular pole pieces with a diameter of 14 mm. Cut the copper glue and aluminum glue into a circular size with a diameter of 14mm. Put a circular pole piece with a diameter of 16mm into a cylindrical mold. The schematic diagram of the mold is as follows figure 2 As shown, make the center of the circular pole piece coincide with the center of the mold. Clamp the upper and lower ends of the mold, use tweezers to scrape off the pole piece dressing on the ring with an outer diameter of 16mm and an inner diameter of 14mm in the circular pole piece with a diameter of 16mm, and obtain a pole piece with a shape similar to a "beer bottle cap" with a center diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com