Non-polar cable insulation and sheath surface marking device and marking process thereof

A cable insulation, non-polar technology, applied in the direction of marking conductors/cables, cable/conductor manufacturing, circuits, etc., can solve the problems of difficult printing and marking, poor adhesion, trouble, etc., to increase versatility and improve qualification. efficiency, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

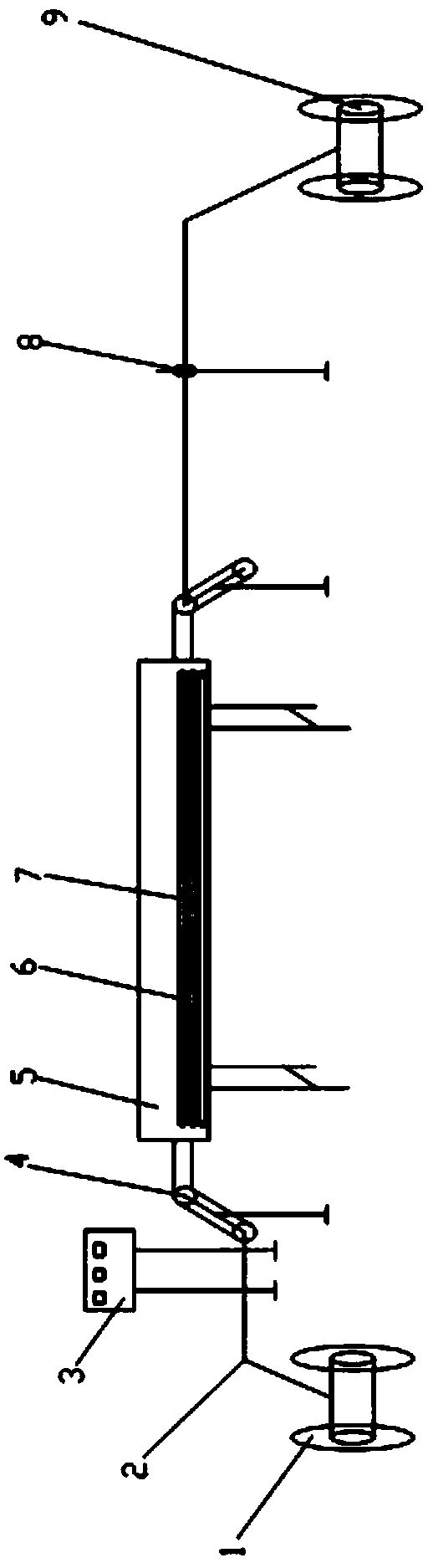

[0022] Such as figure 1 As shown, the insulated wire core 2 is arranged on the pay-off device 1, and a control panel 3 that can set corresponding process parameters according to the material is arranged beside the pay-off device 1, and a control panel 3 is arranged beside the control panel 3 A wire storage device 4 composed of four tension guide wheels, a heat preservation oven 5 for heat preservation is arranged beside the wire storage device 4, and a heating tube 6 for heating is built in the heat preservation oven 5. The middle part of 5 is equipped with thermocouple temperature measuring device 7, described thermocouple temperature measuring device 7 cooperates with control panel 3 and displays the temperature on the control panel 3 in real time, and described insulated wire core 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com