Movable paint spray booth

A spray booth and mobile technology, applied in the spray booth, spraying device, etc., can solve the problems of difficulty in waste gas treatment and increased processing costs, limited movable range of the spray booth, increased volume of the spray booth, etc., to reduce equipment costs , improve the effect and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

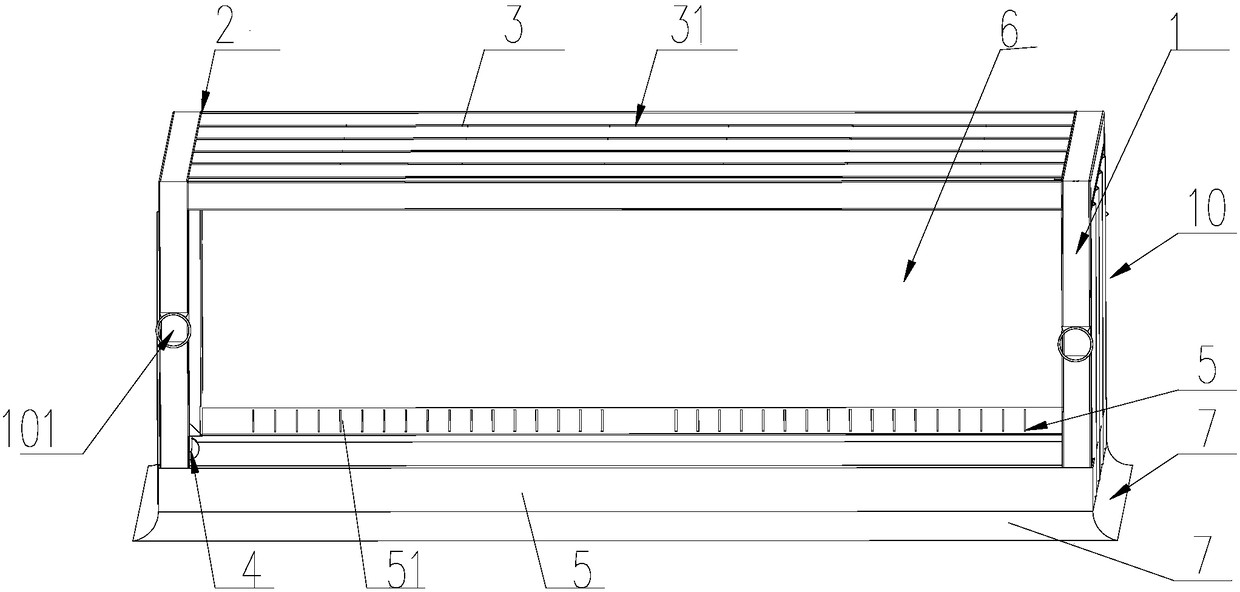

[0033] Example 1 as figure 1 As shown, a mobile spray booth includes four hollow columns 1 and an upper frame 2 arranged on the four columns 1, the upper frame 2 includes two upper beams arranged in parallel, and two hollow and corresponding The longitudinal beam connected to the inner cavity of the column; the two upper beams are detachably connected with the two longitudinal beams.

[0034] The top of the upper frame 2 is detachably provided with a top plate 3, the top plate 3 is provided with a number of air inlet holes 31, the bottom of the column 1 is provided with rollers 4, and the bottom of the four columns 1 is oppositely provided with two hollow air suction collecting pipes 5. The upper frame 2 is provided with a side screen 6 whose lower edge covers at least the suction collecting pipe 5, and a sealing soft board 7 whose lower end is in contact with the ground is provided below the side screen 6. The inner side of the suction collecting pipe 5 is provided with seve...

Embodiment 2

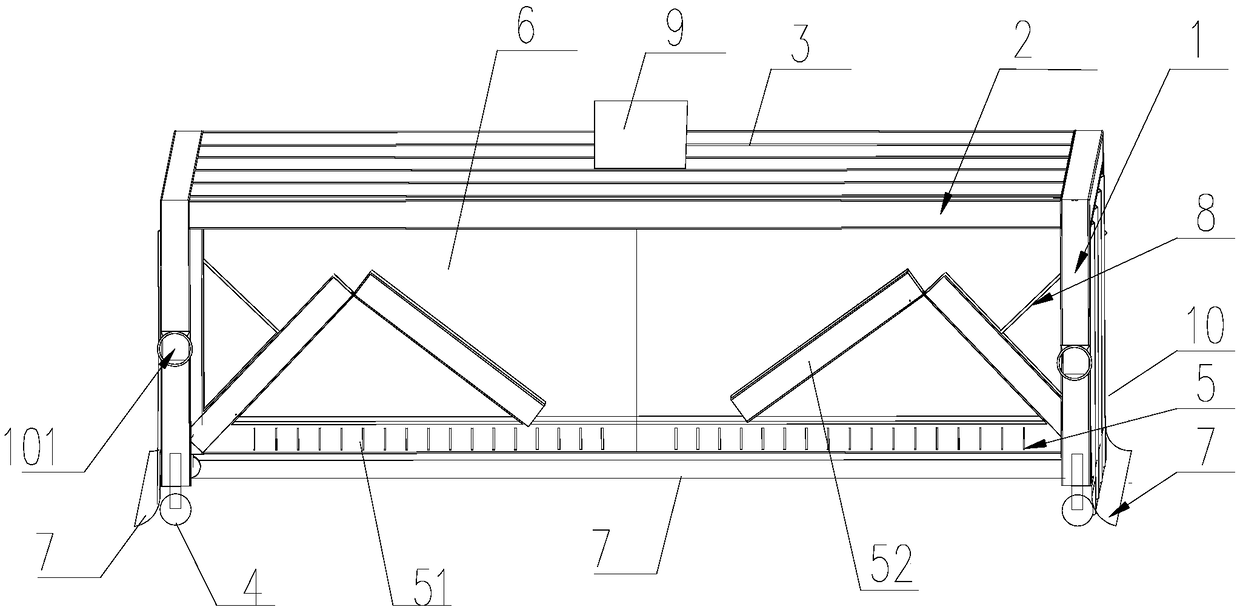

[0036] Example 2 as figure 2As shown, a mobile spray booth includes four hollow columns 1 and an upper frame 2 arranged on the four columns 1, the upper frame 2 includes two upper beams arranged in parallel, and two ends are detachably connected Stringers at the ends of the two upper beams.

[0037] The upper part of the upper frame 2 is detachably provided with a top plate 3 , and the top plate 3 is provided with an air supply assembly 9 . The lower surface of the top plate 3 is provided with a windshield (not shown) which makes the air flow sent into the spray booth evenly transported below the air supply assembly 9 . A roller 4 is provided at the bottom of the column 1 .

[0038] Two hollow suction collection pipes 5 are oppositely arranged under the four columns 1, and the upper frame 2 is provided with a side screen 6 whose lower edge covers at least the suction collection pipe 5, and the side screen 6 is electrically split. Type folding screen, the inner lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com