Disk punching device

A technology of punching device and disc, applied in metal processing and other directions, can solve the problems of inability to process discs with the same indexed holes, incapability of mass production, low work efficiency, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

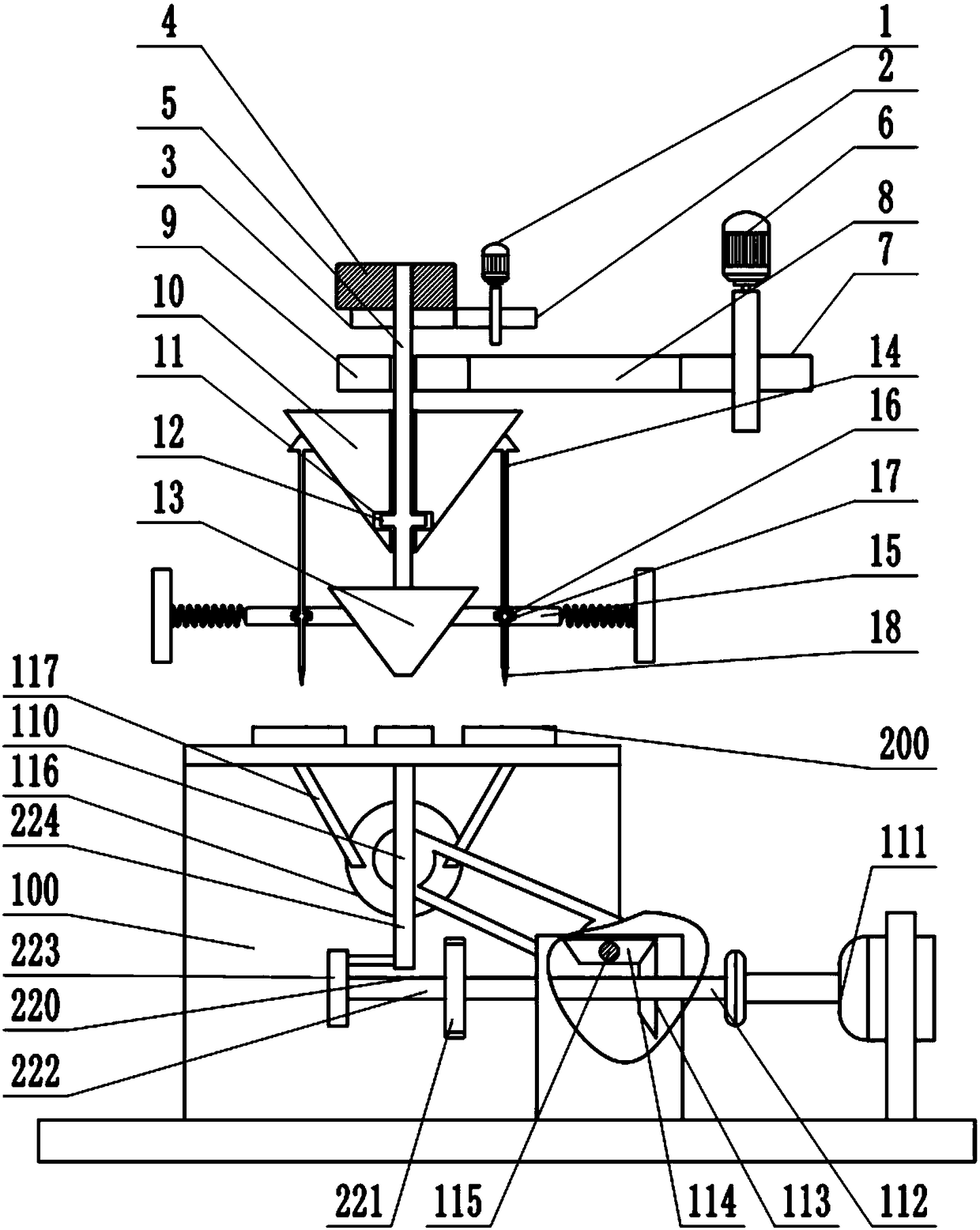

[0021] Such as figure 1 As shown, the disc drilling device includes a frame 4, a driving mechanism, a workbench and a drilling mechanism. The drilling mechanism includes a first motor 1, and the output shaft of the first motor 1 is connected with a driving gear 2, and one side of the driving gear 2 A driven gear 3 meshed with the driving gear 2 is connected, the driven gear 3 is provided with an internal thread, the internal thread hole of the driven gear 3 is provided with a screw 5 matching the internal thread, and the frame 4 is provided with a chute , the screw rod 5 is provided with a bump matching the chute, the screw rod 5 is covered with a conical rotor 10, the conical rotor 10 is driven by a driving mechanism, the driving mechanism includes a second motor 6, and the output shaft of the second motor 6 is connected to There is a driving pulley 7, the driving pulley 7 is connected with a driven pulley 9 through a belt 8, the driven pulley 9 is connected with a driven sha...

Embodiment 2

[0026] The difference between this embodiment and the first embodiment is that the output shaft of the second motor 6 is connected to a gear shaft, and the inner hole of the driving pulley 7 is provided with internal teeth meshing with the gear shaft. When the screw 5 drives the conical rotor 10 to move up and down, it will cause the belt 8 to deviate, which will easily cause the problem of unstable transmission. Through the meshing relationship between the gear 221 shaft and the internal teeth of the driving pulley 7, the driving pulley 7 will Automatically balance the position deviation of the belt 8, thereby bringing stable transmission.

Embodiment 3

[0028] The difference between this embodiment and the first or second embodiment is that: the driven shaft is connected with a telescopic rod, and the lower end of the telescopic rod is fixedly connected with the conical rotor 10 . When the screw rod 5 drives the conical rotor 10 to move up and down, the telescopic rod can ensure that the transmission of the belt 8 is not affected by the movement of the conical rotor 10 by stretching and shortening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com