Anti-rollover system of electric vehicle

An electric vehicle and anti-rollover technology, applied in the field of anti-rollover systems, can solve problems such as complex structure, and achieve the effects of low production cost and reduced risk of rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

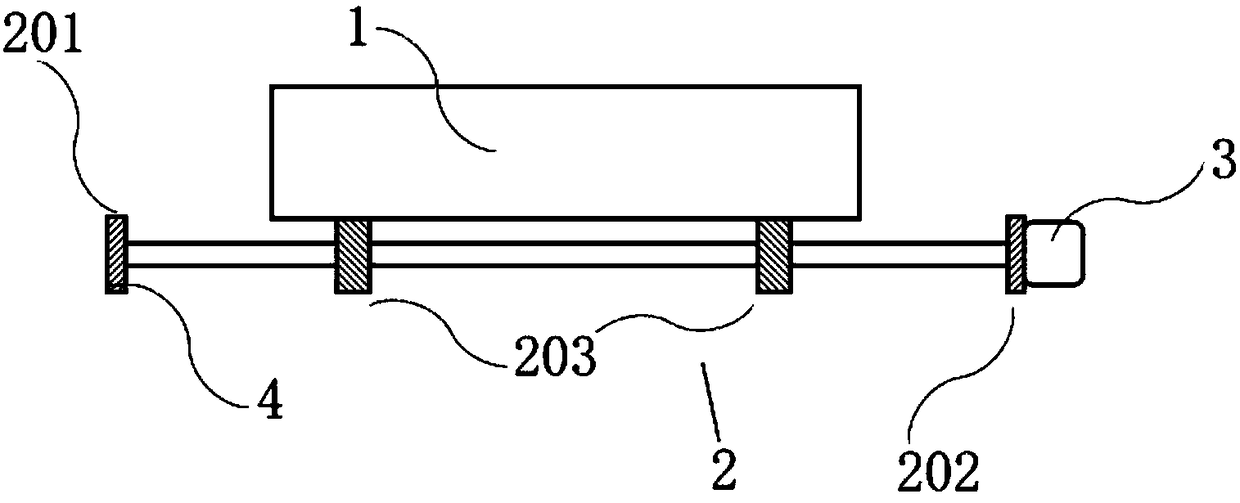

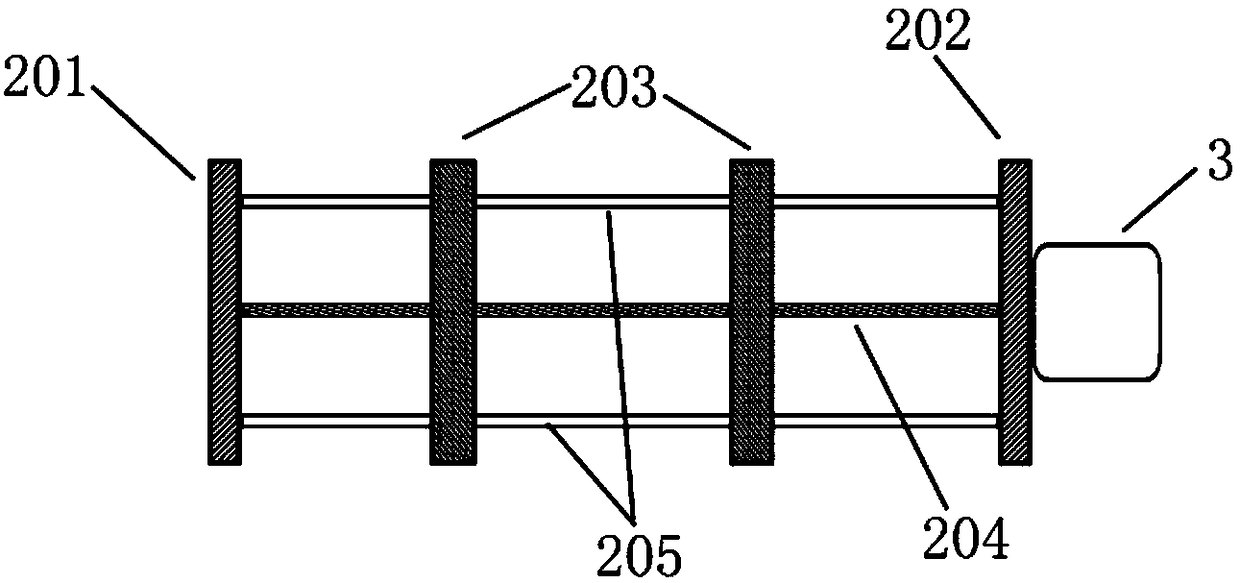

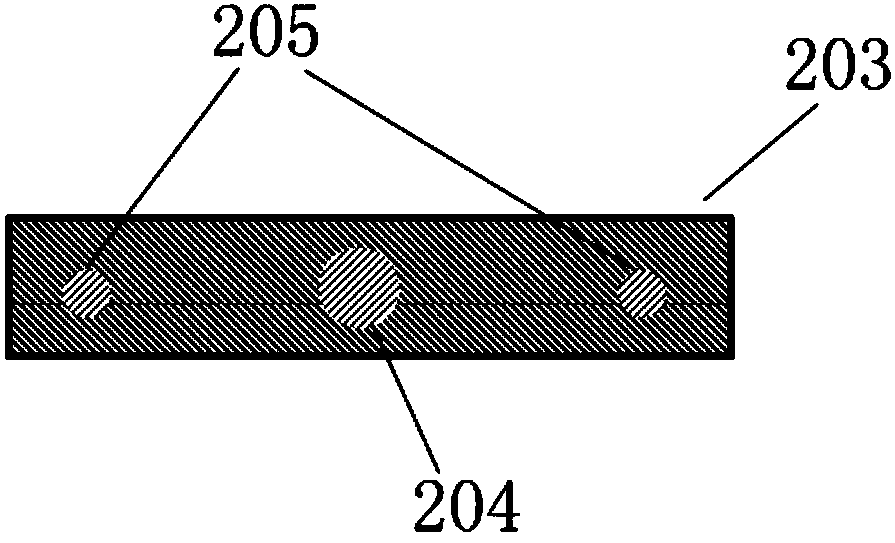

[0022] Such as figure 1 As shown, an anti-rollover system for an electric vehicle includes an electric vehicle battery pack 1 , a screw guide rail 2 , a stepping motor 3 , a PLC controller, and a pressure sensor 4 . The two sides of the bottom of the electric vehicle battery pack 1 are respectively fixed on the two sliders 203 of the screw guide rail 2, the two ends of the screw guide rail 2 are the first support base 201 and the second support base 202, and the stepping motor is fixed on the second support base 202. On the second support base 202, the pressure sensor 4 is fixed below the first support base 201, the data output end of the pressure sensor 4 is connected with the data input end of the PLC controller, the data output end of the PLC is connected with the stepping motor 3, and the PLC controller According to the data collected by the pressure sensor 4, the stepper motor 3 is controlled to rotate forward or reverse to drive the electric vehicle battery pack 1 on the...

Embodiment 2

[0028] Such as Figure 6 As shown, on the basis of Embodiment 1, in order to prevent the electric vehicle battery pack 1 moving at high speed and the body of the electric vehicle from violently colliding under extreme conditions, the first supporting base 201 and the second supporting base 202 can also be respectively Two baffles 5 are added on the side close to the battery pack 1 of the electric vehicle to protect the battery pack 1 of the electric vehicle. In order to increase the protection effect, a layer of elastic material 6 with a thickness of 2-12 mm can be covered on the baffle 5 for buffering , As a preference, use a rubber gasket with a thickness of 8mm. In addition, the stroke of the slider 203 can also be limited on the PCL controller to prevent the electric vehicle battery pack 1 from colliding with the electric vehicle body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com