Connecting method and device of auxiliary framework seats and bearing saddles of wagon self-steering bogie

A technology for railway freight cars and load-bearing saddles, which is applied to bogies, railway car body components, transportation and packaging, etc., can solve the problems of large assembly workload, eliminate welding residual stress, hidden dangers in vehicle operation, and reduce manufacturing accuracy requirements. , Improve system reliability and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

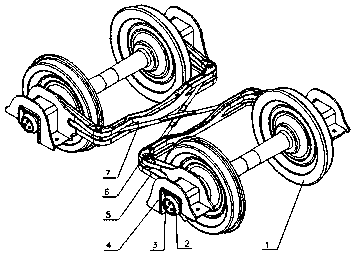

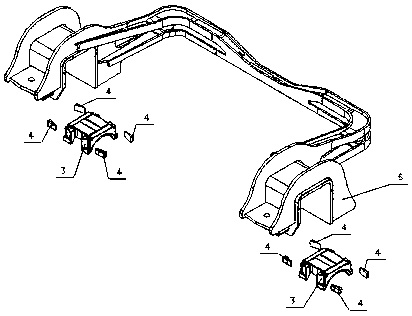

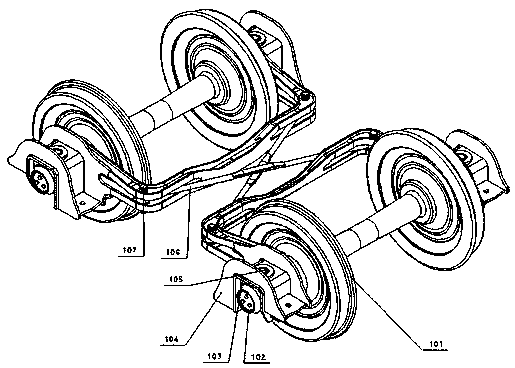

[0036] by attaching Figure 2-6 It can be seen that the present invention relates to a coupling device between a sub-frame seat and a bearing saddle of a self-steering bogie of a railway freight car, including a wheel set, a rolling bearing device, a bearing saddle, a sub-frame, and a cross-connecting rod; wherein, the rolling bearing device is assembled on the wheel set On the journal, the bearing saddle is seated on the outer ring of the rolling bearing device through its arc-shaped surface seat, and the sub-frame and the cross-connecting rod are connected by cylindrical pins. .

[0037] There are two horizontal bearing planes at both ends of the sub-frame; two spherical bosses are symmetrically distributed along the longitudinal direction (vehicle running direction) and transverse direction (parallel to the axis of the axle) on the top of the bearing saddle. At the same time, the longitudinal and transverse centerlines of the bearing saddle top are The point of intersectio...

Embodiment 2

[0045] The structure of the second embodiment is the same as the basic principle of the first embodiment, except that the spherical boss is fixed on the bearing bottom surface of the sub-frame, and the top surface of the bearing saddle is a plane at this time.

[0046] Further, the vertical shaft is fixed on the bearing bottom surface of the sub-frame, and the bearing saddle top surface has a cylindrical hole for fixing the outer ring of the joint bearing.

[0047] Further, the spherical boss on the same top surface of the bearing saddle (or the same bearing surface of the sub-frame) is a cylindrical surface whose axis is located in the vertical symmetry plane of the arc surface of the bearing saddle (vehicle running direction).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com