Liquid mixing preparing container

A liquid mixing and container technology, applied in the direction of containers, mixers, mixing methods, etc., can solve the problems of blocking the outlet of the solution, harm to the health of the operator, and difficulty in proportioning, and achieves a large capacity-pressure conversion rate, convenient and convenient. External supply, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

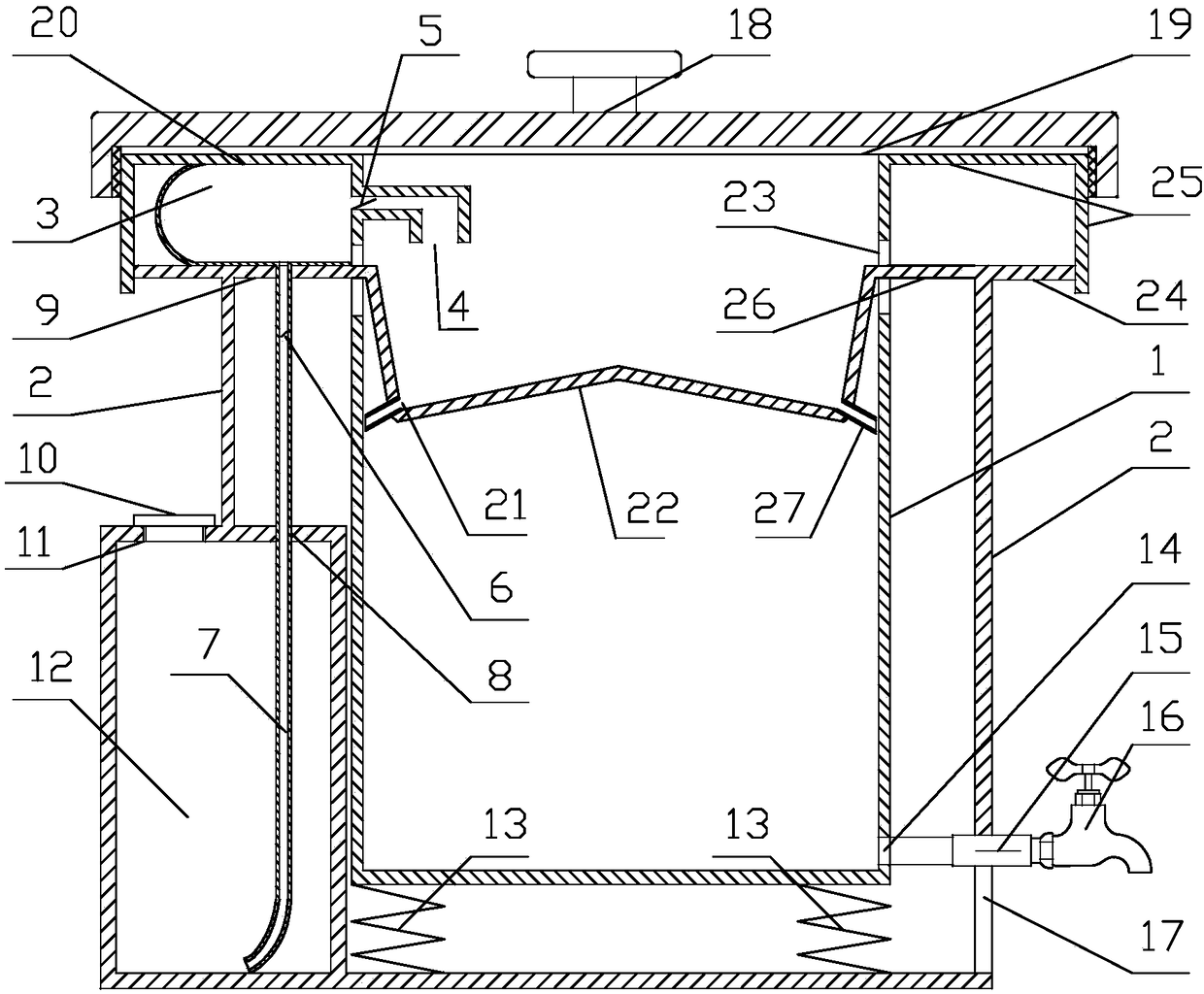

[0024] Below in conjunction with a kind of preferred embodiment and accompanying drawing, the present invention is further described: as figure 1 The shown liquid mixing ingredient container is used to hold liquid mixing ingredients and realize the function of automatic proportioning.

[0025] The container is provided with an inner barrel 1 and an outer barrel 2 with two layers of container walls. The inner barrel 1 is supported by a spring set 13 mounted on the inner bottom surface of the outer barrel 2 and suspended in the air, so the inner barrel and the outer barrel can move relative to each other in the vertical direction. There is a semi-closed interlayer space between the two layers of container walls, and the taken mixed solution is accommodated inside the inner barrel 1 . The initial material is also poured into the inner barrel and mixed with additives in the inner barrel to become a solvent that meets the requirements.

[0026] A partition 9 is provided in the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com