Preparation method of standard quartz powder used for copying silicosis model

A quartz dust, standard technology, applied in the field of preparation of medical model materials, can solve the problems of unreachable dispersion, imitation, and weak pathogenicity, and achieve the effects of simple operation, promotion of research progress, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

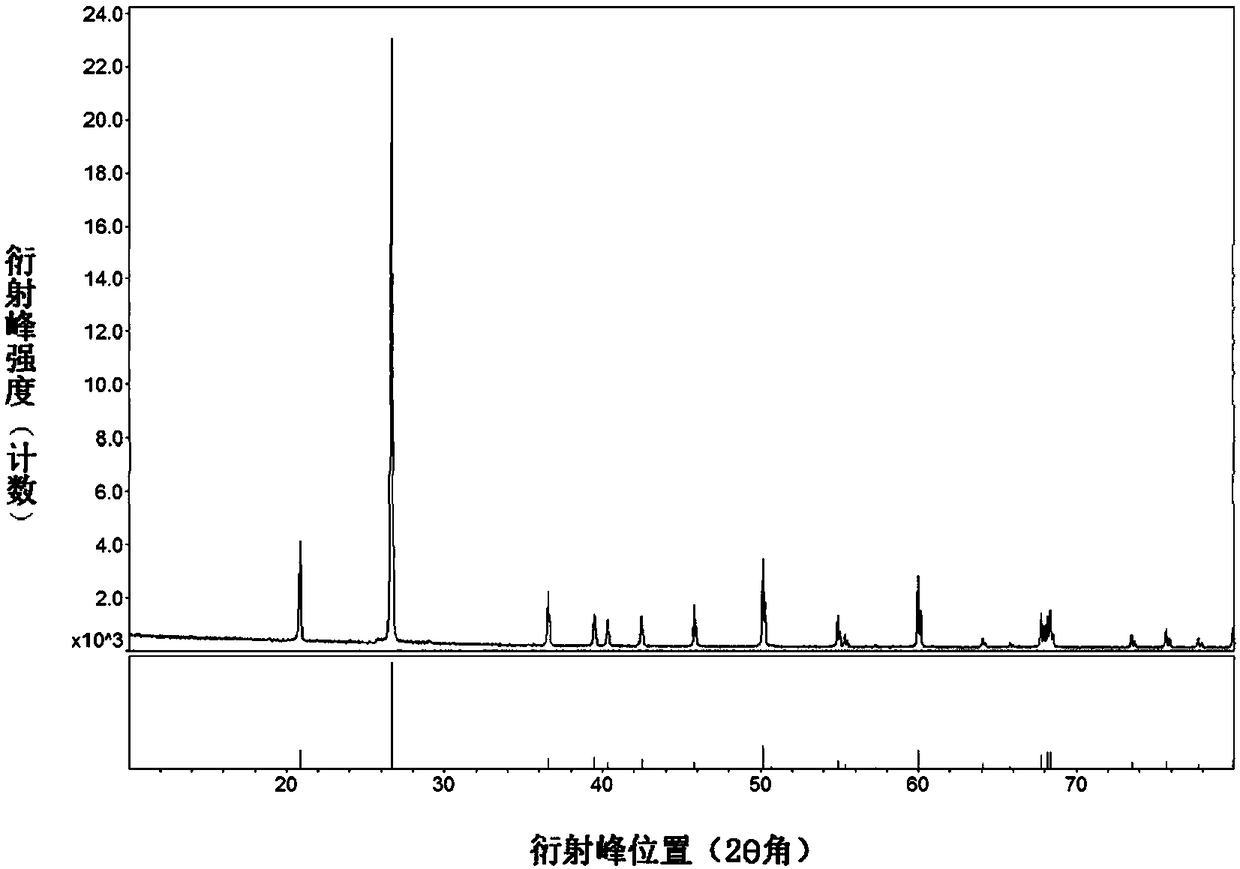

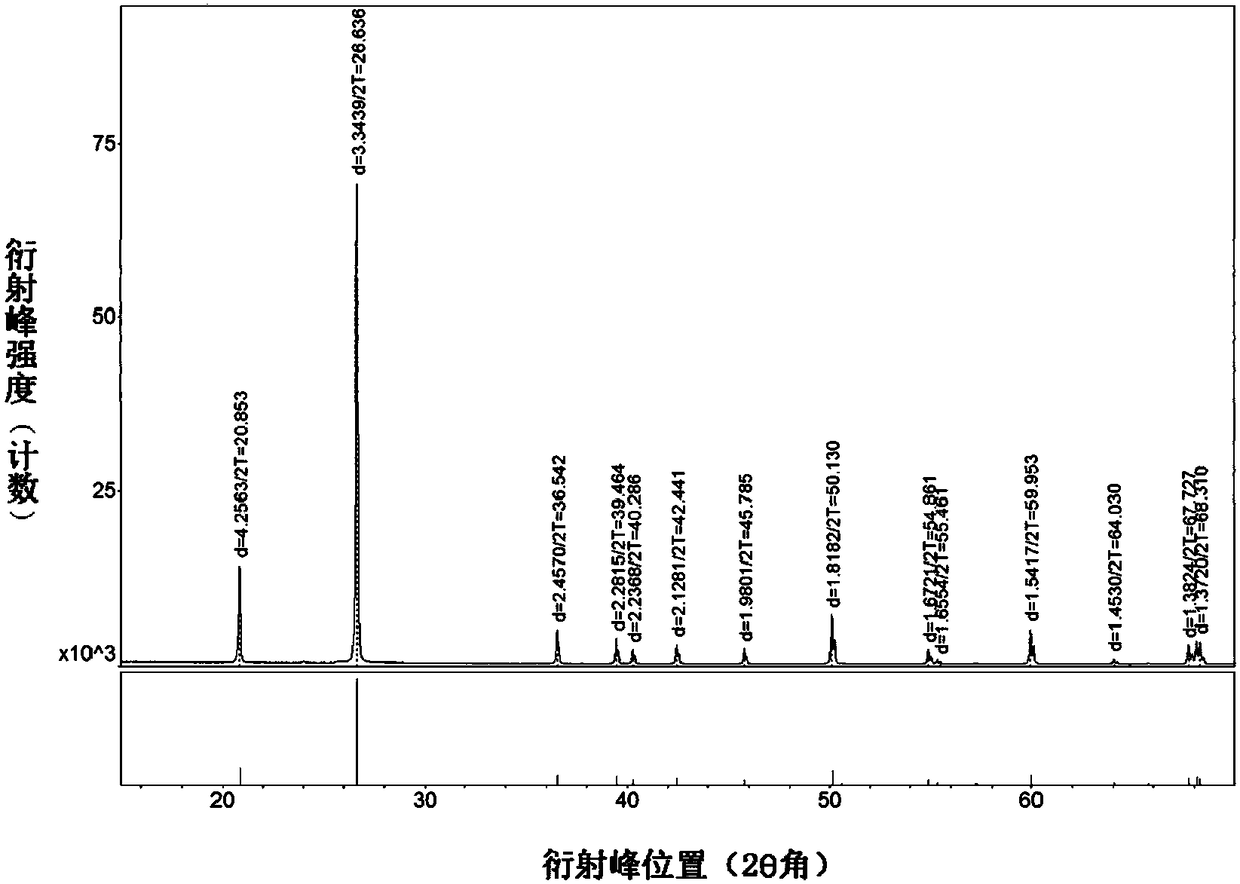

Image

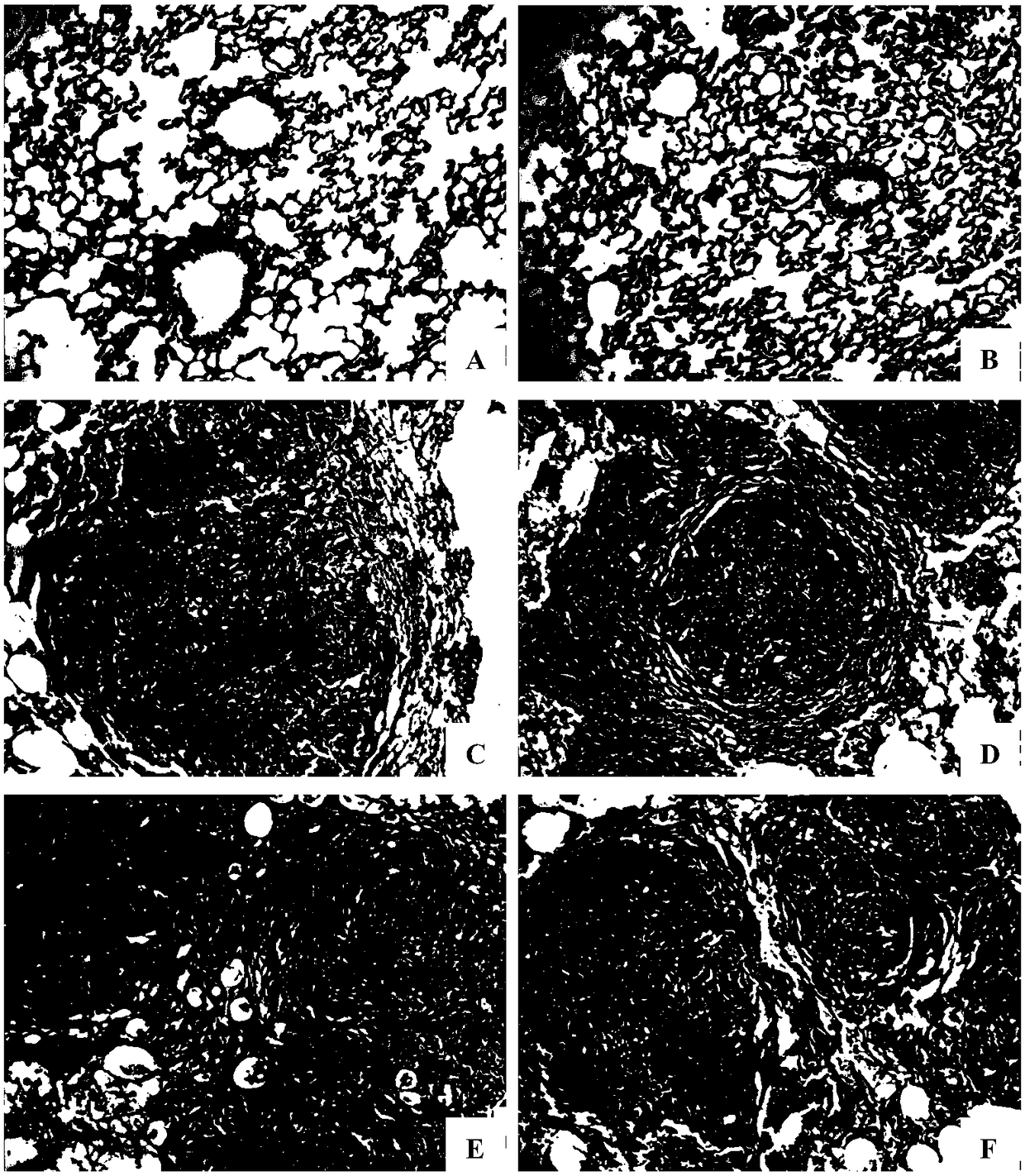

Examples

Embodiment Construction

[0016] 1. Preparation of Quartz Dust

[0017] (1) Selection of quartz raw materials

[0018] Choose 200g of natural quartz crystal block, its purity is 99.28%, that is, free SiO 2 The mass content is 99.28%. Generally speaking, the purer the quartz, the better. After preliminary processing and crushing, the crystal block becomes rough crystal sand, and the rough crystal sand generally has a particle size of 2-5mm.

[0019] (2) Grinding of crystal sand

[0020] Put 1 part of coarse crystal sand and 7 parts of agate balls (that is, the mass ratio is 1:7) into a 500ml agate grinding jar. Ratio of 4:2:1:1:1 for joining. Then add distilled water to the agate grinding jar to a level about 1cm from the mouth of the jar. The weights of the four agate jars should be equal. If they are not equal, use distilled water to adjust them to be equal to maintain a balanced state during grinding. After tightening the sealing cap of the agate jar, place it on a ball mill and grind at a spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com