Composite material for construction and its preparation process

A composite material and preparation technology, which is applied in the field of materials, can solve the problems of excessive bulk density, insufficient mechanical strength, and low thermal conductivity of thermal insulation materials, and achieve excellent thermal insulation effects, good durability, and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

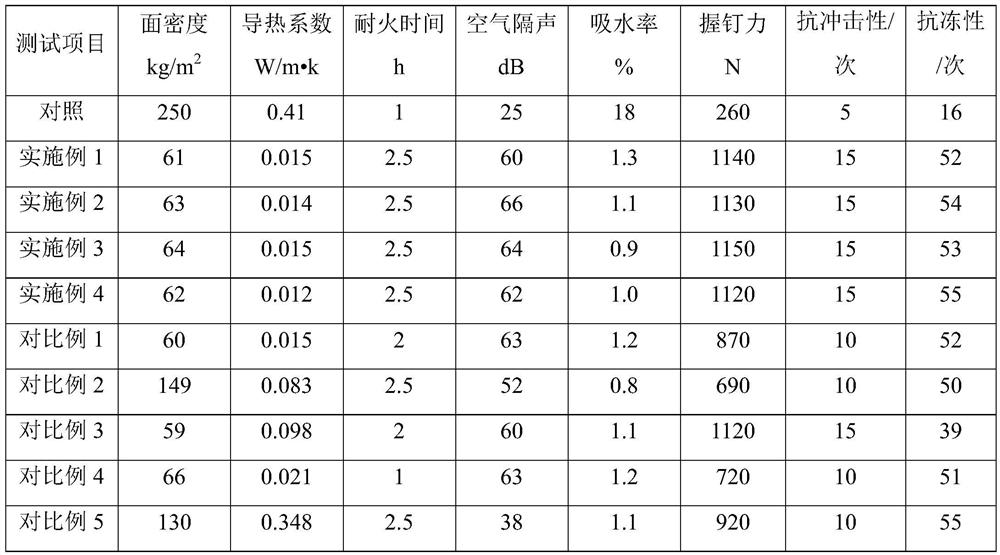

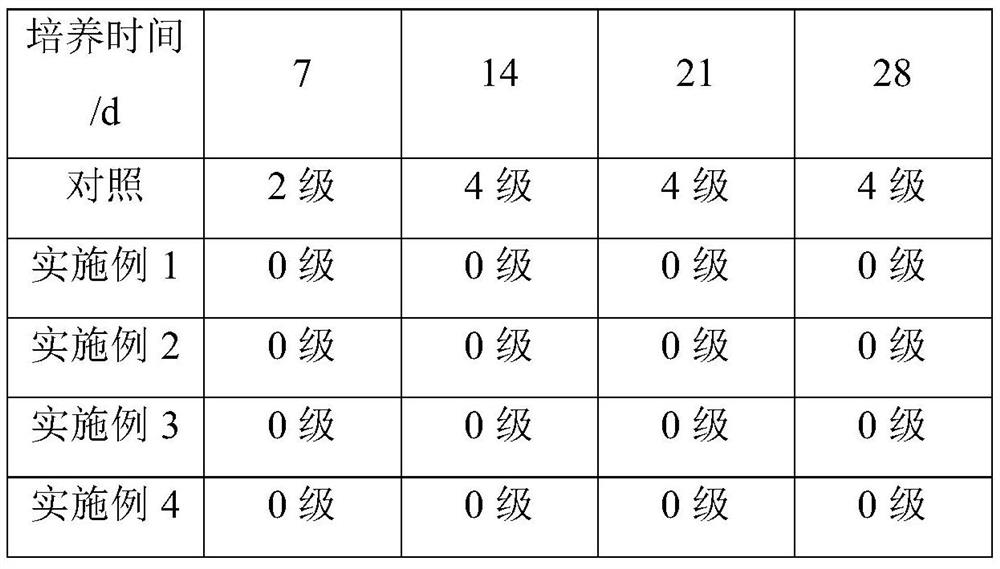

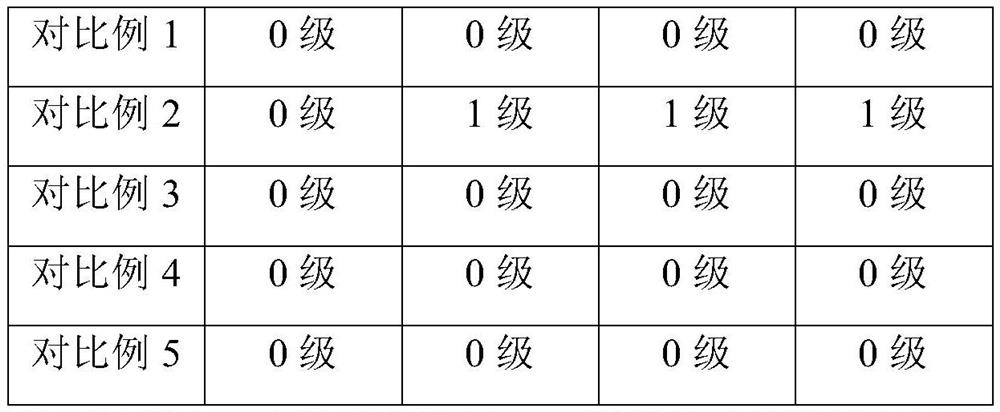

Examples

Embodiment 1

[0038] A composite material for construction, said material is made of the following components in parts by weight: 10 parts of fly ash, 1 part of calcium hydroxide, 5 parts of hemp fiber, 24 parts of fixed phase change material, chopped 5 parts of carbon fiber, 4 parts of modified starch, 13 parts of modified cellulose airgel, 1 part of modified layered dihydroxy compound hydrotalcite, and 21 parts of polyvinyl alcohol.

[0039] Further, the shape-setting phase-change material is a phase-change material fatty acid ternary eutectic, that is, LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) is loaded in a mass ratio of 6:2:2 Expanded perlite and modified diatomaceous earth are on the base material with a mass ratio of 1:1; the mass content of LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) in the shape-setting phase change material is 25 %.

[0040] Further, the length of the chopped carbon fiber is 0.5-1.5mm.

[0041] Further, the modified cellulose airgel is prepared...

Embodiment 2

[0054] A composite material for construction, said material is made of the following components in parts by weight: 12 parts of fly ash, 2 parts of calcium hydroxide, 8 parts of hemp fiber, 28 parts of fixed phase change material, chopped 7 parts of carbon fiber, 5 parts of modified starch, 15 parts of modified cellulose airgel, 2 parts of modified layered dihydroxy composite hydrotalcite, and 24 parts of polyvinyl alcohol.

[0055] Further, the shape-setting phase-change material is a phase-change material fatty acid ternary eutectic, that is, LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) is loaded in a mass ratio of 6:2:2 Expanded perlite and modified diatomaceous earth are on the base material with a mass ratio of 1.2:1; the mass content of LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) in the shape-setting phase change material is 40 %.

[0056] Further, the length of the chopped carbon fiber is 0.5-1.5 mm.

[0057] Further, the modified cellulose airgel is pr...

Embodiment 3

[0070] A composite material for construction, said material is made of the following components in parts by weight: 13 parts of fly ash, 3 parts of calcium hydroxide, 12 parts of hemp fiber, 33 parts of fixed phase change material, chopped 10 parts of carbon fiber, 7 parts of modified starch, 17 parts of modified cellulose airgel, 3 parts of modified layered dihydroxy composite hydrotalcite, and 33 parts of polyvinyl alcohol.

[0071] Further, the shape-setting phase-change material is a phase-change material fatty acid ternary eutectic, that is, LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) is loaded in a mass ratio of 6:2:2 Expanded perlite and modified diatomaceous earth are on the base material with a mass ratio of 1.3:1; the mass content of LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) in the shape-setting phase change material is less than or equal to 55%.

[0072] Further, the length of the chopped carbon fiber is 0.5-1.5mm.

[0073] Further, the modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com