Electrolyte solution, electrolytic copper foil and manufacturing method thereof

A technology of electrolytic copper foil and manufacturing method, applied in electrolytic process, electroforming, etc., can solve problems such as process management difficulty, increased management difficulty, environmental protection cost, and difficult detection of additive concentration, etc., and achieve low roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

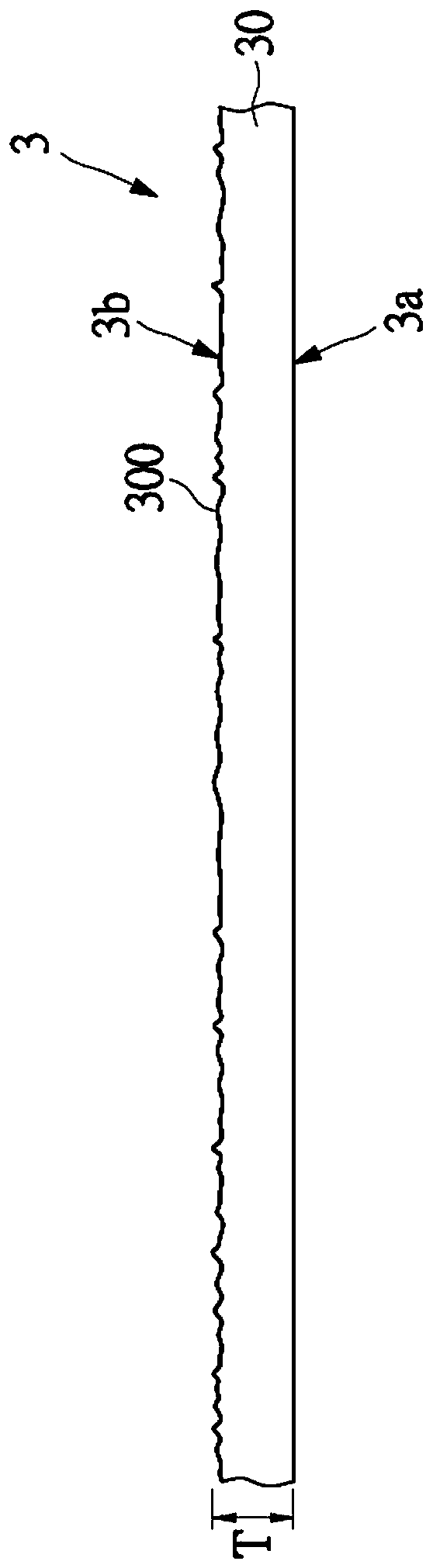

[0043] The following is to illustrate the implementation of the "electrolyte solution, electrolytic copper foil and manufacturing method thereof" disclosed in the present invention through specific specific examples. The concentration of additives in the electrolyte solution provided by the embodiments of the present invention can be reduced to less than 1 ppm, so as to reduce the difficulty in process management. The manufacturing method of the electrolytic copper foil can obtain the electrolytic copper foil with low roughness. In addition, the electrolytic copper foil manufactured by the aforementioned method has special mechanical properties, and can be used as a current collector of a battery, as well as a printed circuit board (PCB) or a flexible printed circuit board (FPC).

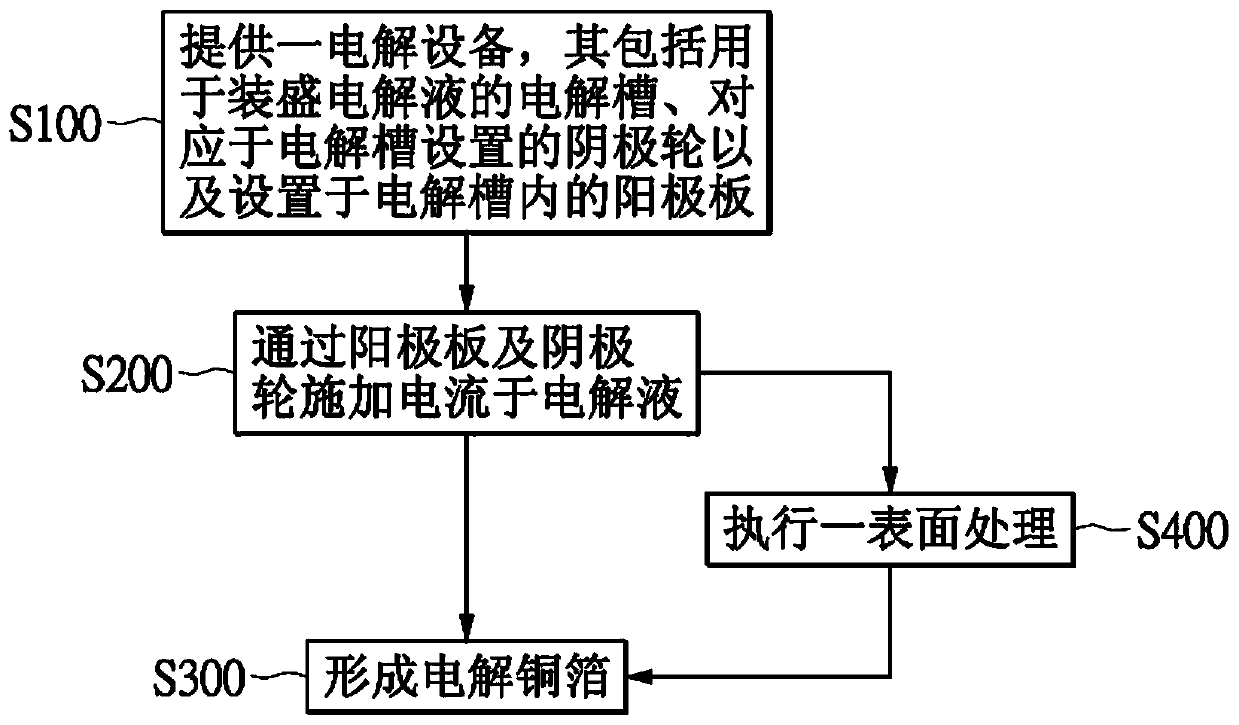

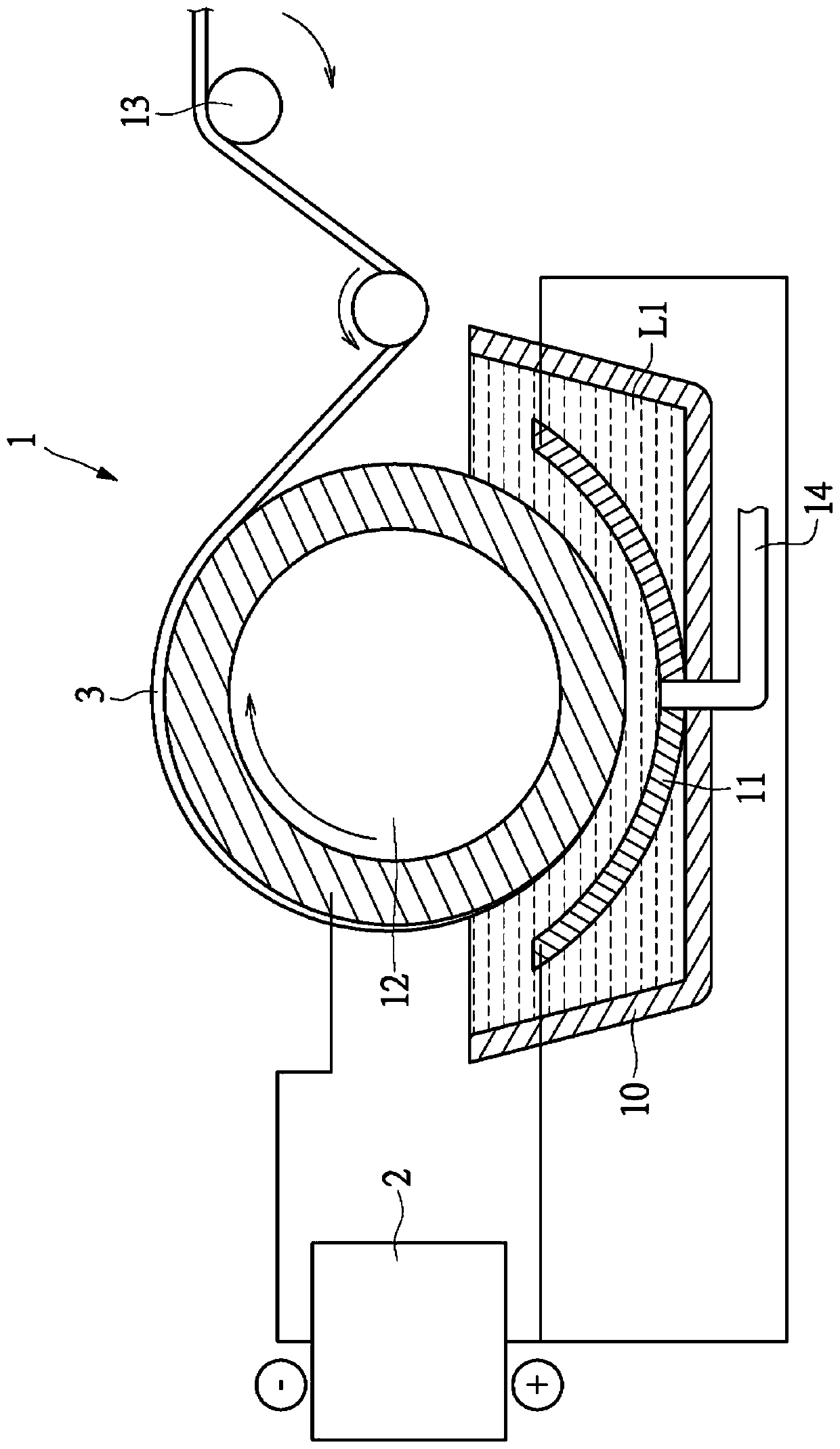

[0044] Please refer to figure 1 , is a flow chart showing a method for manufacturing an electrolytic copper foil according to an embodiment of the present invention. Such as figure 1 As shown, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com