Full-prefabricated assembly type concrete freight transport suspension type monorail structure

A technology of prefabricated concrete and prefabricated assembly, which is applied in infrastructure engineering, tracks, roads, etc., can solve the problems of large environmental pollution, long construction period, and low construction efficiency, and achieve the effects of driving safety, low construction cost, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

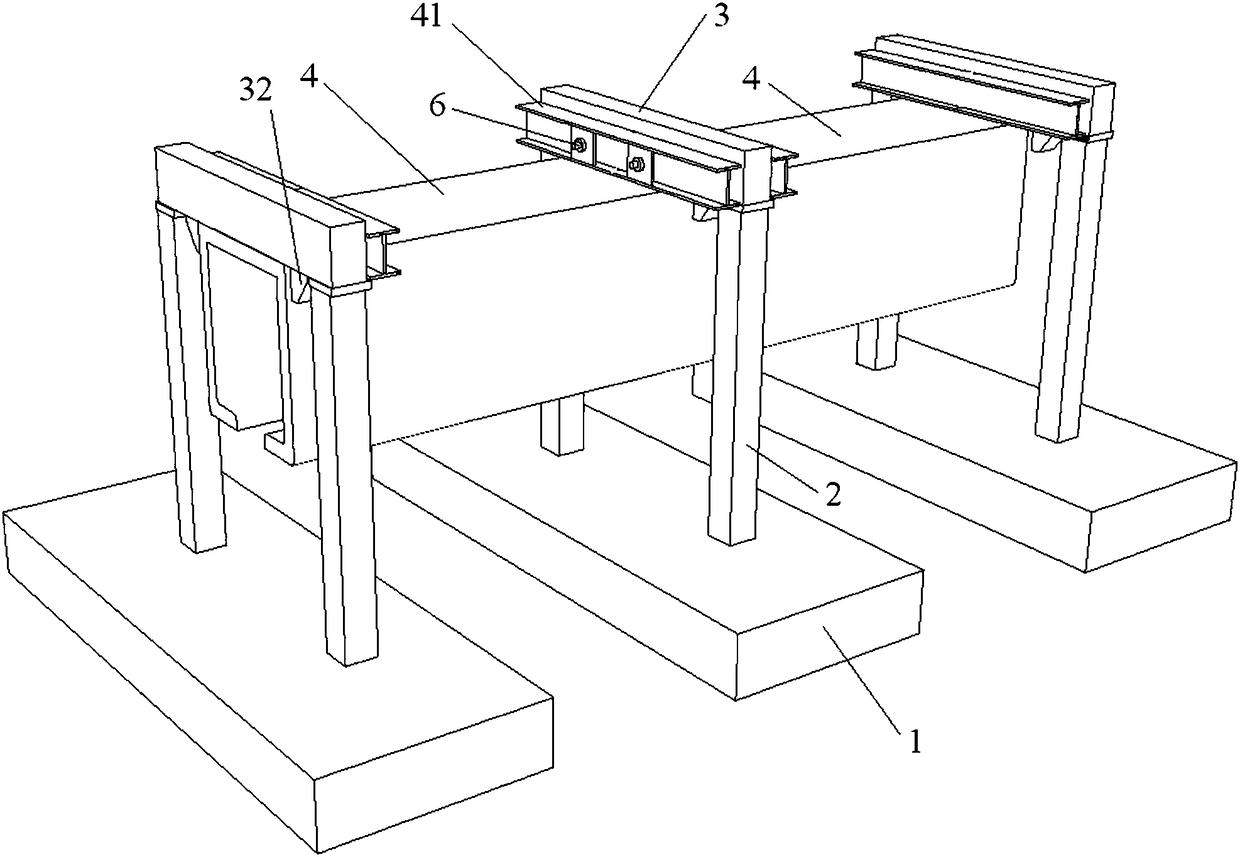

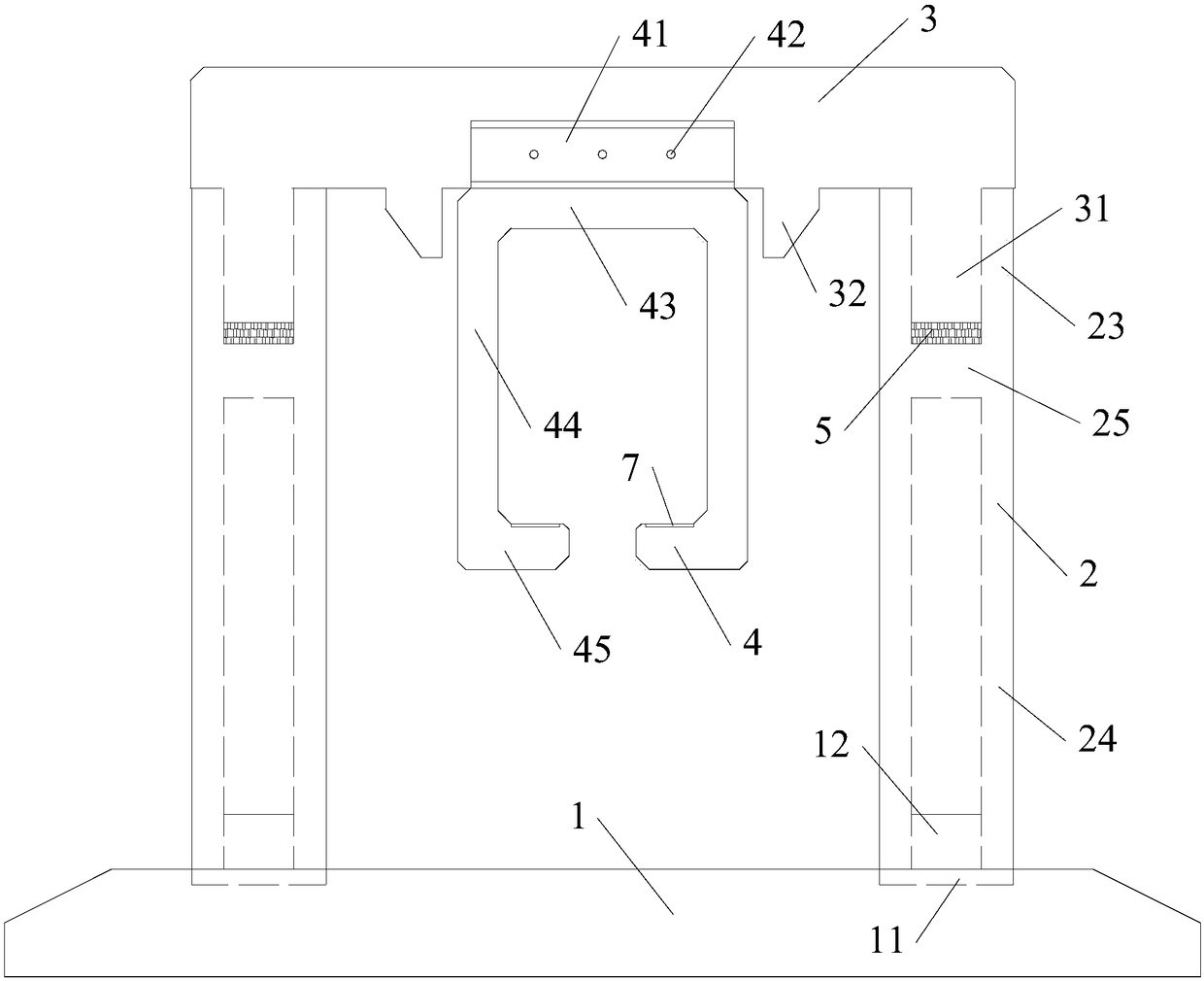

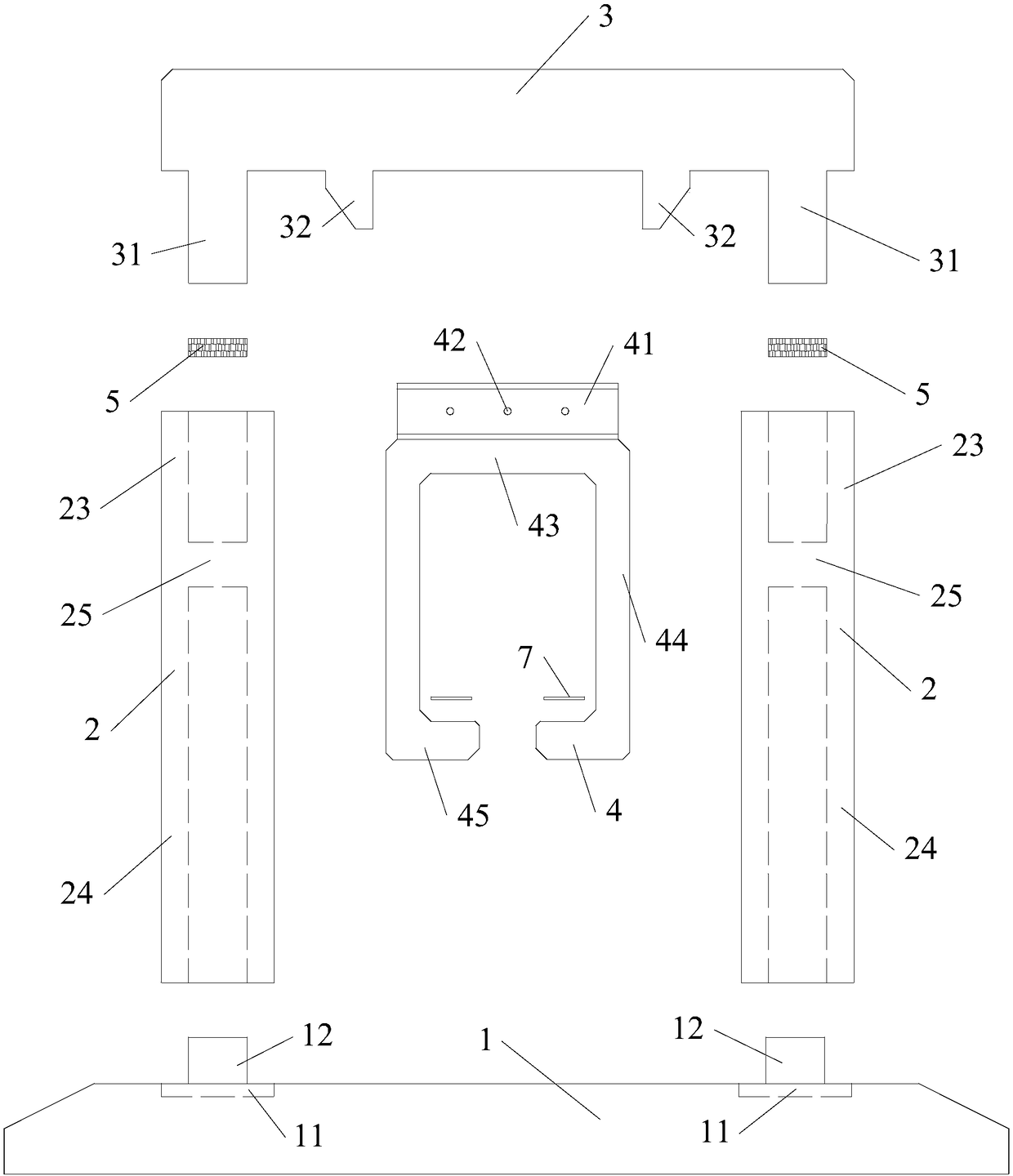

[0059] Such as Figure 1-Figure 5 As shown, a fully prefabricated assembled concrete freight suspension monorail structure includes a prefabricated raft foundation 1 fixed on the ground, a prefabricated hollow concrete pier 2 arranged on the prefabricated raft foundation 1, and erected on the prefabricated The prefabricated concrete crossbeam 3 on the hollow concrete pier 2, and the prefabricated concrete track beam 4 connected under the prefabricated concrete crossbeam 3 by fasteners. in,

[0060] The prefabricated raft foundation 1 is a steel-concrete structure, the prefabricated raft foundation 1 is embedded in the surface of the soil layer, and the prefabricated raft foundation 1 and the prefabricated hollow concrete pier 2 are connected by sleeve grouting. Specifically, such as Figure 6 As shown, the prefabricated raft foundation 1 is pre-processed with a groove 11 with a depth of 3cm-10cm, the groove 11 is provided with a positioning pile 12, and the groove 11 and the...

Embodiment 2

[0074] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the surface part of the prefabricated raft foundation 1 below the soil layer is provided with several protrusions 13, and all the protrusions 13 are arranged in an array, and the protrusions 13 and The prefabricated raft foundation 1 is an integrally formed structure. It is beneficial to increase the contact area between the prefabricated raft foundation 1 and the soil layer, and limit the displacement of the prefabricated raft foundation 1 .

Embodiment 3

[0076] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the prefabricated raft foundation 1 is provided with a sleeve 14 with a height of 10cm-20cm, and the sleeve 14 is used to set the prefabricated hollow concrete pier 2. The size of the inner edge of the sleeve 14 is greater than the size of the outer edge of the prefabricated hollow concrete pier 2, and the prefabricated hollow concrete pier 2 is arranged behind the sleeve 14, and concrete is poured into the sleeve 14 to form a concrete structure, The prefabricated raft foundation 1 and the prefabricated hollow concrete pier 2 are connected.

[0077] The lower part of the sleeve 14 is provided with a grout leakage hole 15. With this structure, after the sleeve 14 is connected to the prefabricated hollow concrete pier 2, the subsequent poured concrete can enter the prefabricated hollow concrete pier 2 from the grout leakage hole 15. The hollow part forms a limit pin structure in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com